A mesh cooling tray allows hot air to circulate evenly around roasted pet food, preventing sogginess and ensuring a crisp texture. In contrast, a rack elevates the food but may restrict airflow underneath, potentially causing uneven cooling and moisture buildup. Choosing a mesh tray optimizes cooling efficiency and preserves the desired roast quality for pet treats.

Table of Comparison

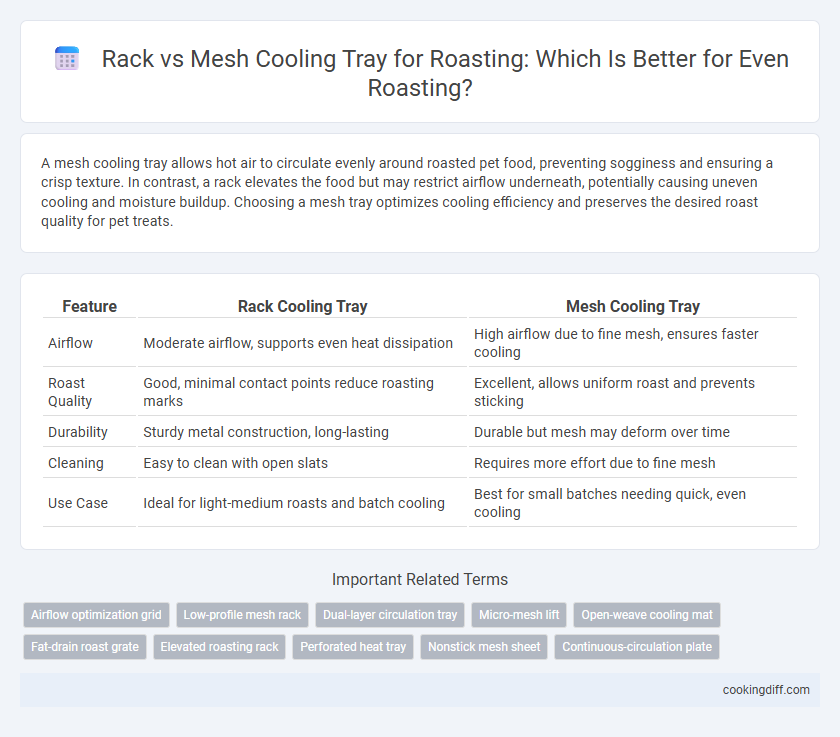

| Feature | Rack Cooling Tray | Mesh Cooling Tray |

|---|---|---|

| Airflow | Moderate airflow, supports even heat dissipation | High airflow due to fine mesh, ensures faster cooling |

| Roast Quality | Good, minimal contact points reduce roasting marks | Excellent, allows uniform roast and prevents sticking |

| Durability | Sturdy metal construction, long-lasting | Durable but mesh may deform over time |

| Cleaning | Easy to clean with open slats | Requires more effort due to fine mesh |

| Use Case | Ideal for light-medium roasts and batch cooling | Best for small batches needing quick, even cooling |

Introduction: Rack vs Mesh Cooling Tray in Roasting

Choosing between a rack and a mesh cooling tray significantly impacts the roasting process and final product quality. Each option offers distinct benefits related to airflow, heat distribution, and ease of use during roasting.

- Rack - Elevates food to allow air circulation beneath, promoting even roasting and browning.

- Mesh Cooling Tray - Features a fine grid that supports smaller items while maximizing airflow from all directions.

- Heat Distribution - Mesh trays typically provide more uniform heat exposure, reducing hotspots compared to standard racks.

Key Differences Between Roasting Racks and Mesh Cooling Trays

What are the key differences between roasting racks and mesh cooling trays? Roasting racks elevate food to allow even heat circulation and fat drainage during cooking, while mesh cooling trays provide a flat, breathable surface ideal for cooling and crisping post-roasting. The design of roasting racks focuses on heat exposure, whereas mesh trays prioritize airflow and moisture escape.

Heat Circulation: Which Provides Better Airflow?

Mesh cooling trays offer superior heat circulation due to their perforated surface, allowing air to flow freely beneath and around food items. This enhanced airflow prevents moisture buildup and promotes even roasting.

Rack cooling trays, while sturdy and supportive, restrict airflow to the bottom of the food, often resulting in less consistent heat distribution. Their solid bars can block air, making them less effective for optimal heat circulation during roasting.

Cooking Evenness: Rack or Mesh Tray Advantage

Mesh cooling trays provide superior airflow beneath the food, promoting more even cooking and consistent roasting results. Racks elevate food to allow fat drainage but may restrict heat circulation compared to mesh trays, potentially causing uneven cooking.

- Mesh Tray Advantage - The fine grid design of mesh trays facilitates optimal heat distribution by exposing more surface area of the food to hot air.

- Rack Limitation - Racks create pockets of stagnant air below the food, which can lead to uneven temperature exposure during roasting.

- Cooking Evenness Outcome - Mesh cooling trays generally produce more uniform browning and doneness due to enhanced airflow compared to racks.

Versatility in the Kitchen: Uses Beyond Roasting

Mesh cooling trays offer enhanced airflow, making them ideal for roasting and evenly cooling delicate baked goods. Rack cooling trays provide sturdy support for heavier items and double as versatile tools for grilling, drying, and even candy making.

- Mesh Cooling Tray - Allows crumbs and excess moisture to fall through, promoting quicker cooling of cookies and pastries.

- Rack Cooling Tray - Supports larger, heavier foods like roasts or poultry without bending or warping.

- Multi-functional Use - Both trays serve as drying racks for herbs and vegetables or a base for pan-frying to drain excess oil.

Choosing between rack and mesh trays expands their utility beyond roasting, adapting to diverse kitchen tasks.

Cleaning and Maintenance Considerations

Mesh cooling trays often require more intensive cleaning due to their fine wire grids that trap coffee oils and chaff, necessitating frequent scrubbing to maintain hygiene. Rack cooling trays feature open slats that facilitate easier debris removal and faster drying, reducing the buildup of residue over time. Regular maintenance is crucial for both types to ensure consistent roasting quality and prevent contamination from old coffee particles.

Durability and Material Quality Comparison

Rack cooling trays typically feature stainless steel construction, offering high durability and resistance to rust and heat damage during roasting. Mesh cooling trays, often made with finer wire mesh, provide good airflow but may use lower-grade metals that can bend or degrade over time under heavy use.

Stainless steel racks maintain structural integrity longer, making them ideal for frequent roasting and handling hot beans. Mesh trays, while promoting even cooling, require more careful handling to avoid warping or material fatigue, impacting their lifespan.

Cost Analysis: Rack vs Mesh Cooling Tray

Rack cooling trays typically cost more upfront due to their sturdy construction and materials but offer longer durability and easier maintenance. Mesh cooling trays are usually less expensive initially but may wear out faster and require more frequent replacements, increasing overall costs over time. Choosing between the two depends on balancing initial investment against long-term value and operational efficiency.

Suitability for Different Foods: Meat, Vegetables, and More

Mesh cooling trays provide even airflow, making them ideal for roasting smaller or irregularly shaped foods like vegetables and nuts. Rack cooling trays are better suited for larger cuts of meat as they allow fat to drip away, promoting crispiness and browning.

Mesh trays prevent delicate items from falling through, preserving their shape during roasting. Meat benefits from racks that elevate it, ensuring heat surrounds the surface evenly for thorough cooking. Both trays enhance roasting results but should be chosen based on the type and size of food.

Related Important Terms

Airflow optimization grid

Mesh cooling trays enhance roasting quality by allowing superior airflow through their perforated surfaces, promoting even heat distribution and faster cooling compared to traditional racks. Rack trays limit airflow with solid bars, often causing uneven roasting and hotspots, whereas mesh grids optimize thermal exposure for consistent bean development.

Low-profile mesh rack

Low-profile mesh racks offer superior airflow and even heat distribution during roasting compared to traditional racks, preventing hotspots and ensuring consistent roast quality. Their fine mesh design supports smaller coffee beans or nuts while allowing chaff and debris to fall through, enhancing roasting efficiency and cleanup.

Dual-layer circulation tray

A dual-layer circulation tray combines the benefits of rack and mesh cooling trays by enhancing airflow through both perforated surfaces and elevated racks, promoting even roasting and optimal heat dissipation. This design reduces bean scorching and accelerates cooling, improving overall roasting consistency and flavor development.

Micro-mesh lift

Micro-mesh lift trays offer superior airflow and even heat distribution compared to traditional rack cooling trays, minimizing roast inconsistencies and enhancing bean quality. The fine mesh design prevents smaller beans from falling through while allowing optimal cooling speed, crucial for achieving a balanced flavor profile during the roasting process.

Open-weave cooling mat

Open-weave cooling mats provide superior airflow and even heat distribution compared to traditional rack or mesh cooling trays, enhancing roasting uniformity and crispness. Their breathable design prevents moisture buildup and allows for faster cooling, making them ideal for maintaining food texture and quality post-roast.

Fat-drain roast grate

Fat-drain roast grates on rack trays offer superior airflow, allowing excess fat to drain away during roasting, resulting in crispier, less greasy meats. Mesh cooling trays, while providing a more uniform surface, often retain fat beneath the meat, which can lead to less effective fat drainage and soggier textures.

Elevated roasting rack

Elevated roasting racks improve airflow around the food, promoting even heat distribution and crispier textures compared to mesh cooling trays that may trap moisture underneath. The solid surface of a rack prevents small pieces from falling through while allowing fat to drip away, enhancing roasting efficiency and flavor.

Perforated heat tray

Perforated heat trays offer superior airflow and even heat distribution during roasting compared to rack or mesh cooling trays, reducing hot spots and enhancing the Maillard reaction for optimal flavor development. Their design minimizes moisture buildup and ensures consistent roasting by allowing hot air to circulate freely around the food, improving texture and overall cooking efficiency.

Nonstick mesh sheet

Nonstick mesh trays offer superior airflow and even heat distribution compared to traditional racks, enhancing the roasting process by promoting consistent browning and reducing sticking. Their fine mesh design allows juices to drip away while maintaining food stability, making cleanup easier and ensuring a crisp finish on roasted items.

Rack vs mesh cooling tray for roasting. Infographic

cookingdiff.com

cookingdiff.com