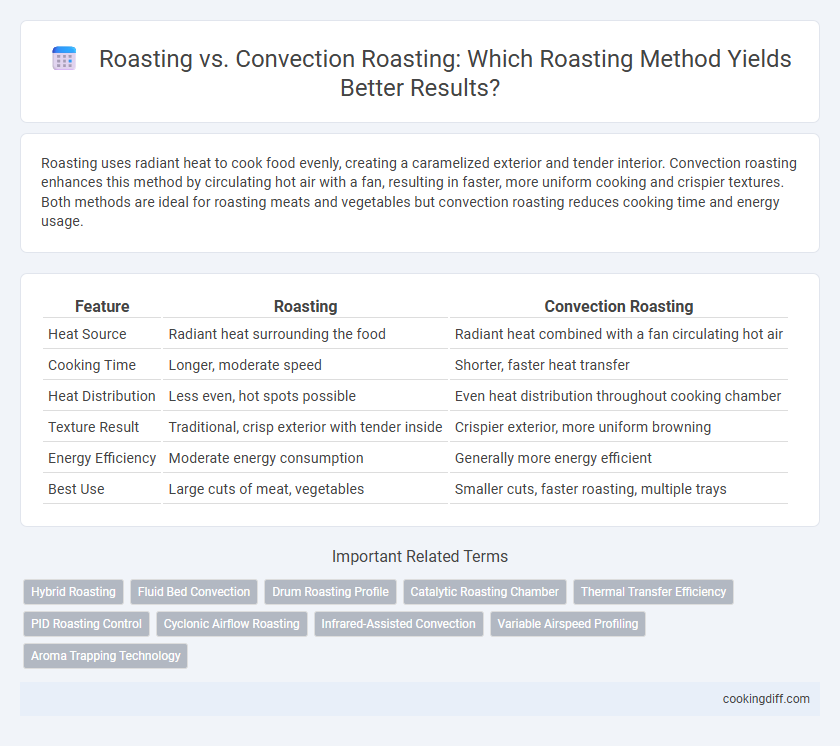

Roasting uses radiant heat to cook food evenly, creating a caramelized exterior and tender interior. Convection roasting enhances this method by circulating hot air with a fan, resulting in faster, more uniform cooking and crispier textures. Both methods are ideal for roasting meats and vegetables but convection roasting reduces cooking time and energy usage.

Table of Comparison

| Feature | Roasting | Convection Roasting |

|---|---|---|

| Heat Source | Radiant heat surrounding the food | Radiant heat combined with a fan circulating hot air |

| Cooking Time | Longer, moderate speed | Shorter, faster heat transfer |

| Heat Distribution | Less even, hot spots possible | Even heat distribution throughout cooking chamber |

| Texture Result | Traditional, crisp exterior with tender inside | Crispier exterior, more uniform browning |

| Energy Efficiency | Moderate energy consumption | Generally more energy efficient |

| Best Use | Large cuts of meat, vegetables | Smaller cuts, faster roasting, multiple trays |

Introduction to Roasting Methods

Roasting is a dry-heat cooking method that uses hot air to cook food evenly, typically in an oven. It enhances flavor through caramelization and Maillard reactions, resulting in a crisp, browned exterior and juicy interior.

Convection roasting improves this process by circulating hot air with a fan, which speeds cooking and promotes more uniform heat distribution. This method reduces cooking time and enhances browning, making it ideal for large cuts of meat and whole poultry.

What is Traditional Roasting?

Traditional roasting involves cooking food by surrounding it with dry heat in an oven at a consistent temperature. This method relies on radiant heat from the oven walls to cook the food evenly, typically resulting in a crispy exterior and tender interior.

- Heat Source - Utilizes radiant heat without the use of a fan to circulate air.

- Cooking Time - Usually requires a longer cooking period compared to convection roasting.

- Texture and Flavor - Produces a classic browned crust and retains natural juices effectively.

This method focuses on steady, uniform heat rather than air circulation, distinguishing it from convection roasting.

Understanding Convection Roasting

Convection roasting utilizes a fan to circulate hot air evenly around the food, resulting in faster and more uniform cooking compared to traditional roasting. This method enhances Maillard reactions, producing a crisp exterior while maintaining juicy interiors, ideal for meats and vegetables. Understanding convection roasting helps optimize temperature settings and cooking times to achieve consistent results and energy efficiency.

Key Differences Between Roasting and Convection Roasting

Roasting uses radiant heat from the oven walls to cook food evenly, while convection roasting employs a fan to circulate hot air, speeding up cooking and promoting browning. Convection roasting typically produces crispier exteriors and juicier interiors due to the efficient heat distribution.

- Heat Source - Roasting relies on static radiant heat, whereas convection roasting uses a fan to distribute hot air.

- Cooking Speed - Convection roasting reduces cooking time by circulating hot air evenly around the food.

- Texture Outcome - Convection roasting produces a crunchier exterior and retains moisture better than traditional roasting.

Temperature and Time Comparison

| Roasting Method | Temperature Range | Cooking Time |

|---|---|---|

| Traditional Roasting | 325degF - 375degF (163degC - 190degC) | Longer; depends on meat size, typically 20-30 minutes per pound |

| Convection Roasting | 300degF - 350degF (149degC - 177degC) | Shorter; reduces cooking time by approximately 25% due to air circulation |

Impact on Food Texture and Flavor

Roasting uses radiant heat that surrounds the food, creating a crispy, browned exterior while keeping the interior moist, enhancing natural flavors with caramelization. This method intensifies complex, savory notes, especially in meats and vegetables, resulting in a rich texture contrast.

Convection roasting employs a fan to circulate hot air evenly, which promotes faster and more uniform cooking, producing a consistently crisp outer layer without drying out the food. The enhanced airflow also preserves moisture inside, leading to a juicier texture and well-balanced flavor development throughout the dish.

Best Foods for Each Roasting Method

Roasting uses dry heat to evenly cook foods and is ideal for items that benefit from caramelization and browning. Convection roasting circulates hot air with a fan, promoting faster, more even cooking without drying out the food.

- Traditional Roasting excels with large cuts of meat - Beef roasts and whole chickens develop a deep crust and tender interior.

- Convection Roasting suits vegetables and smaller cuts - Brussels sprouts, potatoes, and chicken wings roast quickly with crisp, evenly browned surfaces.

- Delicate foods benefit from convection roasting - Fish fillets cook evenly while retaining moisture due to more controlled heat distribution.

Equipment Needed for Roasting vs Convection Roasting

Roasting requires a conventional oven or a rotisserie with consistent dry heat to cook food evenly. Convection roasting uses the same oven equipped with a fan and exhaust system, which circulates hot air for faster and more uniform cooking. The primary difference in equipment lies in the convection oven's fan technology that enhances heat distribution compared to standard roasting methods.

Energy Efficiency and Cooking Consistency

Which method offers better energy efficiency and cooking consistency: roasting or convection roasting? Convection roasting uses a fan to circulate hot air, reducing cooking time and energy consumption compared to traditional roasting. This method also ensures more even heat distribution, resulting in consistent cooking results and less temperature fluctuation.

Related Important Terms

Hybrid Roasting

Hybrid roasting combines the even heat distribution of convection roasting with the intense, direct heat of traditional roasting, enhancing flavor development and tenderness in meats. This method optimizes cooking efficiency and preserves moisture, resulting in a perfectly roasted dish with a crispy exterior and juicy interior.

Fluid Bed Convection

Fluid bed convection roasting uses a stream of hot air to suspend and roast items uniformly, resulting in even heat distribution and faster cooking times compared to traditional roasting, which relies on radiant heat. This method enhances energy efficiency and produces a consistent texture with minimal risk of scorching or uneven roasting.

Drum Roasting Profile

Drum roasting offers precise control of temperature and bean agitation, ensuring even heat distribution and consistent development of coffee's flavor complexity compared to convection roasting, which relies primarily on hot air circulation and may result in uneven roast profiles. The drum roasting profile allows for slower heat ramp rates and extended Maillard reactions, enhancing caramelization and producing a richer, more balanced cup.

Catalytic Roasting Chamber

Catalytic roasting chambers enhance roasting by utilizing a catalytic converter to efficiently oxidize gases, reducing emissions and improving flavor development compared to traditional convection roasting. This method promotes uniform heat distribution and precise temperature control, resulting in consistent roast quality and energy efficiency.

Thermal Transfer Efficiency

Roasting relies primarily on radiant heat and conduction, which can result in uneven cooking and longer cooking times compared to convection roasting. Convection roasting utilizes a fan to circulate hot air evenly, significantly enhancing thermal transfer efficiency by reducing hot and cold spots and speeding up the cooking process.

PID Roasting Control

PID roasting control enhances the precision of both traditional roasting and convection roasting by continuously adjusting temperature based on real-time feedback, ensuring optimal heat distribution and consistent browning. While convection roasting leverages hot air circulation for even cooking, PID control refines this process by minimizing temperature fluctuations, resulting in superior flavor development and texture.

Cyclonic Airflow Roasting

Cyclonic airflow roasting enhances heat distribution by circulating hot air rapidly around the food, resulting in even browning and crispy textures without the need for added fats. Compared to traditional convection roasting, this method reduces cooking time and improves moisture retention, offering a more efficient and flavorful roasting experience.

Infrared-Assisted Convection

Infrared-assisted convection roasting combines the rapid, high-heat benefits of infrared radiation with the even heat distribution of convection, resulting in faster cooking times and enhanced flavor development compared to traditional convection roasting. This method improves Maillard reaction efficiency and moisture retention, producing juicier, more evenly cooked foods with a crisp exterior.

Variable Airspeed Profiling

Variable Airspeed Profiling in roasting enables precise control over heat distribution and airflow, enhancing flavor development and texture by adjusting airspeed at different roasting stages. Compared to convection roasting, which uses a constant airflow, this method optimizes the roasting process for improved uniformity and complexity in the final product.

Roasting vs Convection Roasting for roasting method. Infographic

cookingdiff.com

cookingdiff.com