Roasting whole poultry creates a crispy, golden skin while allowing the meat to develop deep, caramelized flavors through dry heat exposure. Salt crust baking envelops the bird in a thick layer of salt that traps moisture, resulting in exceptionally juicy and tender meat with subtle seasoning. Both methods enhance the texture and taste of poultry but differ in flavor intensity and moisture retention.

Table of Comparison

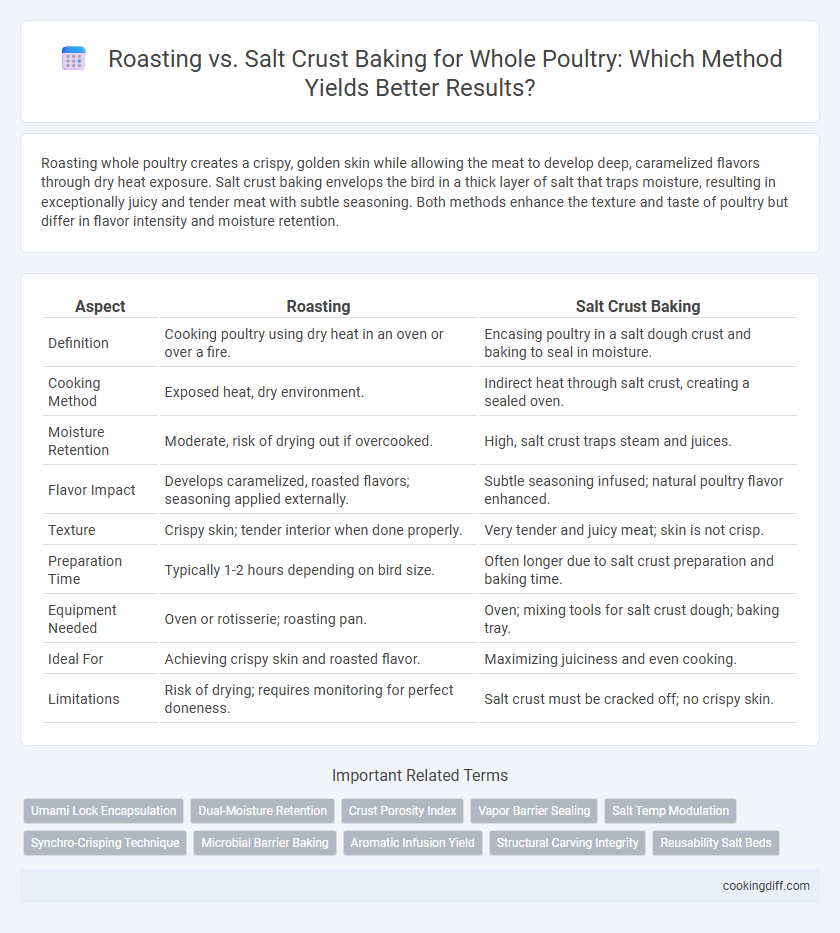

| Aspect | Roasting | Salt Crust Baking |

|---|---|---|

| Definition | Cooking poultry using dry heat in an oven or over a fire. | Encasing poultry in a salt dough crust and baking to seal in moisture. |

| Cooking Method | Exposed heat, dry environment. | Indirect heat through salt crust, creating a sealed oven. |

| Moisture Retention | Moderate, risk of drying out if overcooked. | High, salt crust traps steam and juices. |

| Flavor Impact | Develops caramelized, roasted flavors; seasoning applied externally. | Subtle seasoning infused; natural poultry flavor enhanced. |

| Texture | Crispy skin; tender interior when done properly. | Very tender and juicy meat; skin is not crisp. |

| Preparation Time | Typically 1-2 hours depending on bird size. | Often longer due to salt crust preparation and baking time. |

| Equipment Needed | Oven or rotisserie; roasting pan. | Oven; mixing tools for salt crust dough; baking tray. |

| Ideal For | Achieving crispy skin and roasted flavor. | Maximizing juiciness and even cooking. |

| Limitations | Risk of drying; requires monitoring for perfect doneness. | Salt crust must be cracked off; no crispy skin. |

Introduction to Whole Poultry Cooking Techniques

What distinguishes roasting from salt crust baking when preparing whole poultry? Roasting exposes the bird to dry heat, resulting in a crispy skin and rich, caramelized flavors. Salt crust baking envelops the poultry in a thick salt mixture, preserving moisture and producing exceptionally tender meat without additional seasoning.

What Is Traditional Roasting?

Traditional roasting involves cooking whole poultry in an open oven with dry heat, which crisps the skin and enhances flavor through caramelization. This method contrasts with salt crust baking, where the bird is encased in a salt mixture to retain moisture and infuse seasoning during cooking.

- Heat exposure - Dry heat directly cooks the poultry's surface, creating a browned and crispy exterior.

- Flavor development - Maillard reactions during roasting produce rich, savory flavors and aromas.

- Texture contrast - Roasting yields a crisp skin and tender, juicy meat inside.

Traditional roasting remains a popular technique for achieving a flavorful and visually appealing roasted poultry dish.

Understanding Salt Crust Baking

Salt crust baking involves encasing whole poultry in a thick layer of salt, which creates a sealed environment that locks in moisture and heat. This method allows the bird to cook evenly and retain its natural juices, resulting in exceptionally tender and flavorful meat.

Unlike roasting, where direct dry heat can cause moisture loss and uneven cooking, salt crust baking uses the insulating properties of salt to maintain consistent temperature and prevent drying out. The hardened salt crust also enhances flavor infusion and makes carving easier as the bird emerges perfectly cooked.

Flavor Development: Roasting vs Salt Crust Baking

Roasting whole poultry enhances flavor through Maillard reactions, creating a browned, savory crust and deep caramelization. Salt crust baking seals moisture and infuses subtle seasoning without intense browning, preserving the meat's natural taste.

- Roasting develops complex flavors - High, dry heat induces Maillard reactions that produce rich, savory notes and crispy skin.

- Salt crust baking retains moisture - The salt encasement traps steam, keeping the poultry juicy and tender.

- Salt crust imparts mild seasoning - The poultry absorbs a gentle saltiness, enhancing flavor without overpowering the natural profile.

Moisture Retention and Juiciness Compared

Roasting whole poultry exposes it to dry heat, which can lead to moisture loss, while salt crust baking encases the bird in a salt mixture that traps steam and preserves juices. The salt crust acts as a natural barrier, enhancing moisture retention and resulting in a juicier, more tender texture compared to traditional roasting. Studies show salt crust baking can retain up to 20% more moisture, significantly improving the overall succulence of poultry dishes.

Texture Differences in Finished Poultry

Roasting whole poultry typically results in a crispy, browned skin with a tender, evenly cooked interior due to dry heat exposure. Salt crust baking creates a sealed environment that locks in moisture, producing exceptionally juicy meat with a slightly firmer texture beneath the preserved skin.

Texture differences between the two methods are notable: roasting offers a more pronounced contrast between the crunchy exterior and soft meat, while salt crust baking yields a consistently moist and tender bite throughout. The salt crust acts as a natural barrier, preventing moisture loss and enhancing the poultry's natural flavors without the need for additional basting. Roasting is ideal for those seeking a traditional crispy skin, whereas salt crust baking is preferred for maintaining optimal juiciness and subtle flavor retention in the finished poultry.

Required Equipment and Preparation Steps

Roasting whole poultry requires a roasting pan, oven, and a meat thermometer to ensure even cooking and proper internal temperature. Salt crust baking involves encasing the bird in a salt mixture, necessitating a large baking dish and ample coarse salt, combined with egg whites and herbs to form the crust. Preparation for roasting focuses on seasoning and trussing the bird, while salt crust baking demands careful coverage of the poultry to create a sealed salt shell that retains moisture during cooking.

Cooking Time and Temperature Considerations

Roasting whole poultry requires maintaining an oven temperature between 350degF and 400degF, with cooking times typically ranging from 20 to 25 minutes per pound to ensure even browning and thorough doneness. Salt crust baking, by contrast, involves encasing the bird in a salt mixture that insulates and retains moisture, allowing the poultry to cook at a consistent temperature closer to 375degF but often for a slightly longer duration.

While roasting exposes the bird directly to dry heat, promoting a crisp skin, salt crust baking protects the meat from direct heat, resulting in a juicier texture but slower heat penetration that demands precise temperature control. Both methods require an internal poultry temperature of 165degF for safe consumption, but salt crust baking's heat distribution can affect the time needed to reach this target.

Serving and Presentation Styles

| Roasting | Provides a crispy, golden-brown skin ideal for direct serving, enhancing visual appeal and texture contrast. Plates are often garnished with roasted vegetables or herbs, emphasizing a rustic, hearty presentation. |

| Salt Crust Baking | Encases the poultry in a hardened salt shell that is cracked open tableside, creating an interactive serving experience. This method preserves moisture and flavor, resulting in tender meat that is delicately sliced and elegantly plated. |

Related Important Terms

Umami Lock Encapsulation

Roasting whole poultry enhances Maillard reactions, intensifying umami flavors by breaking down proteins and fats, whereas salt crust baking encapsulates moisture and natural juices, preserving umami compounds within the meat. The salt crust acts as a barrier, locking in umami-rich amino acids and nucleotides, resulting in a juicier, more flavorful poultry experience compared to the drier texture often associated with roasting.

Dual-Moisture Retention

Roasting whole poultry enhances Maillard reaction flavors and develops crispy skin, while salt crust baking encases the bird in a salt layer, creating a moist environment that seals in juices for superior dual-moisture retention. The combination of dry heat in roasting and salt's hygroscopic properties during salt crust baking prevents excessive moisture loss, preserving tenderness and juiciness throughout cooking.

Crust Porosity Index

Roasting typically yields a lower crust porosity index compared to salt crust baking, resulting in a firmer, less porous outer layer that enhances moisture retention while developing deep caramelization. Salt crust baking creates a highly porous crust due to salt's hygroscopic properties, which allows steam exchange and tenderizes whole poultry more effectively while preserving juiciness.

Vapor Barrier Sealing

Roasting creates a dry heat environment that crisps the skin and enhances flavor through Maillard reactions, while salt crust baking forms a vapor barrier by encasing the whole poultry in salt, trapping moisture and ensuring juiciness. The salt crust's vapor barrier sealing retains steam within the bird, preventing moisture loss and resulting in tender, evenly cooked meat compared to the drier texture typical of roasting.

Salt Temp Modulation

Salt crust baking for whole poultry uses salt as a thermal insulator, enabling precise salt temperature modulation to maintain consistent heat distribution and moisture retention. Roasting typically subjects poultry to direct dry heat, which can cause uneven cooking and moisture loss compared to the controlled temperature environment created by the salt crust method.

Synchro-Crisping Technique

Roasting whole poultry develops a deep, caramelized skin and evenly cooked meat, while salt crust baking locks in moisture and flavors through an insulated salt shell, ensuring juicy results. The Synchro-Crisping Technique combines the best of both methods by initially roasting to render fat and crisp the skin, then applying a salt crust to retain moisture, producing perfectly tender and flavorful poultry with a crispy finish.

Microbial Barrier Baking

Roasting exposes whole poultry to direct dry heat, effectively reducing surface microbial load through high temperatures and crispy skin formation, while salt crust baking encases the bird in a salt layer that acts as a natural microbial barrier, retaining moisture and preventing bacterial contamination during cooking. Salt crust baking maintains a controlled, insulated environment that limits oxygen exposure and pathogen growth more effectively than traditional roasting methods.

Aromatic Infusion Yield

Roasting whole poultry enhances aromatic infusion yield by allowing direct exposure to dry heat, which caramelizes the skin and intensifies natural flavors. In contrast, salt crust baking traps moisture and volatile compounds, resulting in a more subtle but deeply penetrating aroma throughout the meat.

Structural Carving Integrity

Roasting whole poultry preserves structural carving integrity by evenly rendering fat and firming muscle fibers, allowing clean, precise slices without collapsing the meat. Salt crust baking encases the bird in a hardened layer that locks in moisture but can cause uneven cooking and a fragile surface, compromising carving stability.

Roasting vs Salt Crust Baking for whole poultry. Infographic

cookingdiff.com

cookingdiff.com