Roasting chicken produces a crispy skin and deep, caramelized flavors due to dry heat cooking, while steam-assisted roasting combines dry heat with steam to retain moisture and create a juicier texture. Steam-assisted roasting reduces cooking time and prevents the chicken from drying out, making it ideal for leaner cuts. The method chosen depends on whether you prioritize crispy skin or enhanced juiciness and tenderness.

Table of Comparison

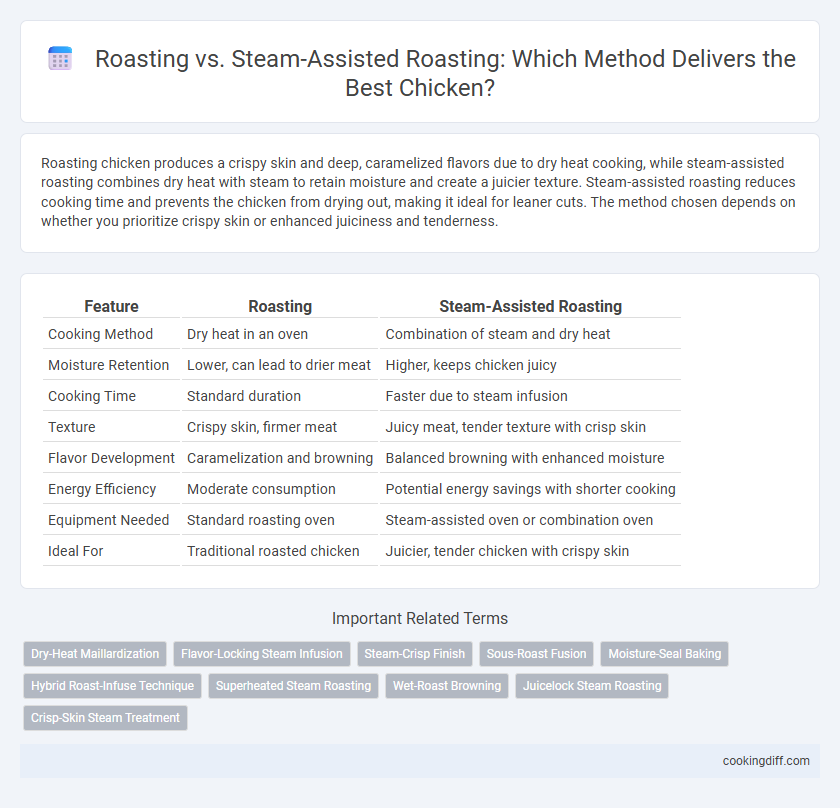

| Feature | Roasting | Steam-Assisted Roasting |

|---|---|---|

| Cooking Method | Dry heat in an oven | Combination of steam and dry heat |

| Moisture Retention | Lower, can lead to drier meat | Higher, keeps chicken juicy |

| Cooking Time | Standard duration | Faster due to steam infusion |

| Texture | Crispy skin, firmer meat | Juicy meat, tender texture with crisp skin |

| Flavor Development | Caramelization and browning | Balanced browning with enhanced moisture |

| Energy Efficiency | Moderate consumption | Potential energy savings with shorter cooking |

| Equipment Needed | Standard roasting oven | Steam-assisted oven or combination oven |

| Ideal For | Traditional roasted chicken | Juicier, tender chicken with crispy skin |

Traditional Roasting for Chicken: An Overview

Traditional roasting of chicken involves cooking the bird in a dry heat environment, usually an oven, which enhances flavor through caramelization and Maillard browning. This method typically results in a crispy skin and tender, juicy meat when done correctly.

- Heat Source - Uses dry heat, often at temperatures between 350degF to 450degF, to evenly cook the chicken.

- Texture Outcome - Yields a crispy exterior while maintaining moisture inside the meat.

- Cooking Time - Usually requires 20 minutes per pound to ensure thorough cooking and safe internal temperature.

What Is Steam-Assisted Roasting?

What is steam-assisted roasting and how does it differ from traditional roasting? Steam-assisted roasting involves cooking chicken with added moisture in the oven, which helps retain juiciness and tenderness. This method uses a humid environment to prevent drying out, resulting in a more flavorful and evenly cooked chicken compared to conventional dry heat roasting.

Flavor Differences: Roasting vs Steam-Assisted Roasting

Roasting chicken develops a deep, caramelized flavor through Maillard browning, resulting in a crispy skin and rich, concentrated taste. This dry heat method intensifies natural chicken flavors by evaporating moisture and creating a savory crust.

Steam-assisted roasting preserves moisture within the chicken while still allowing some browning, producing a juicier texture with a milder flavor profile. The added steam softens the skin, reducing crispness but enhancing overall succulence and tenderness.

Moisture Retention in Chicken: Which Method Wins?

Roasting chicken traditionally involves dry heat, which can result in moisture loss and drier meat. Steam-assisted roasting introduces steam during the cooking process, significantly improving moisture retention and yielding juicier chicken.

Studies show steam-assisted roasting maintains internal moisture levels better than conventional roasting by creating a humid environment that reduces evaporation. This method produces tender, succulent chicken while preserving flavor and texture. For chefs prioritizing juicy meat, steam-assisted roasting is the superior technique.

Texture Comparison: Classic Roast vs Steam-Infused Roast

Classic roasting produces a crisp, golden-brown skin with a firm, well-cooked interior. Steam-assisted roasting retains more moisture, resulting in a juicier texture with slightly less crust formation.

- Crispness - Classic roast achieves a crunchier exterior due to dry heat exposure.

- Moisture retention - Steam infusion helps maintain internal juiciness by reducing moisture loss.

- Texture contrast - Steam-assisted roasting creates a tender bite with a softer skin compared to the traditional roast.

Overall, steam-assisted roasting balances moisture and tenderness, while classic roasting emphasizes crisp skin and firm texture.

Cooking Time: Standard Roasting vs Steam-Assisted

Standard roasting chicken typically requires cooking times of 45 to 60 minutes at 375degF, ensuring a crispy skin and even browning. Steam-assisted roasting reduces cooking time by approximately 15-20%, thanks to the moist environment accelerating heat transfer and preventing drying out.

Steam-assisted roasting maintains juiciness and tenderness by combining dry heat with steam, resulting in faster cooking without compromising texture. This method is especially beneficial for larger cuts, as it shortens overall roasting durations while preserving flavor and moisture.

Nutrient Preservation During Roasting Methods

Roasting chicken at high temperatures can lead to the loss of heat-sensitive vitamins such as B vitamins and vitamin C. Steam-assisted roasting helps preserve nutrients by maintaining moisture and preventing nutrient degradation through a gentler cooking environment. Studies show that steam-assisted methods retain higher levels of antioxidants and protein quality compared to conventional dry roasting.

Equipment Needed for Each Roasting Style

Traditional roasting requires a conventional oven capable of maintaining consistent dry heat, while steam-assisted roasting needs a combi oven that can generate both steam and dry heat simultaneously. Steam-assisted roasting equipment provides precise humidity control, essential for maintaining moisture in chicken during cooking.

- Conventional Oven - Standard roasting involves using a dry heat oven with adjustable temperature settings for even cooking.

- Combi Oven - Steam-assisted roasting requires a specialized oven that combines steam injection with traditional baking functions.

- Humidity Control System - Essential in steam-assisted roasting to regulate moisture levels, preventing the chicken from drying out.

Energy Efficiency: Traditional vs Steam-Assisted Roasting

Steam-assisted roasting of chicken reduces energy consumption by enhancing heat transfer and moisture retention, leading to shorter cooking times compared to traditional dry roasting. Traditional roasting requires higher temperatures and longer durations, resulting in increased energy usage and potential moisture loss. Incorporating steam-assisted techniques offers a sustainable alternative with improved energy efficiency and better texture preservation.

Related Important Terms

Dry-Heat Maillardization

Roasting enhances chicken's flavor through dry-heat Maillardization, producing a crispy, browned crust rich in complex aromas and savory notes. Steam-assisted roasting moderates surface dehydration, resulting in a juicier interior but a less pronounced Maillard reaction, yielding a softer crust with milder flavor development.

Flavor-Locking Steam Infusion

Roasting chicken with steam-assisted technology enhances flavor-locking by infusing moisture during the cooking process, resulting in juicier, more tender meat compared to traditional dry roasting. This method preserves natural juices and intensifies the savory profile, creating a superior taste experience with crispy skin and succulent interior.

Steam-Crisp Finish

Steam-assisted roasting enhances chicken by injecting steam during cooking, which maintains moisture and produces a tender interior, while the high dry heat crisps the skin to a golden, crackling finish. This method delivers a superior balance of juiciness and a distinctive, crisp texture compared to traditional roasting that often results in drier meat and less uniformly crispy skin.

Sous-Roast Fusion

Sous-Roast Fusion combines traditional roasting with steam-assisted technology, enhancing moisture retention and flavor infusion in chicken through precise temperature control and steam circulation. This method outperforms conventional dry roasting by producing juicier, tender meat with a crispier skin and reduced cooking time.

Moisture-Seal Baking

Roasting preserves chicken's natural flavors while dry heat forms a crispy skin, yet steam-assisted roasting enhances moisture retention by creating a humid environment that prevents drying. Moisture-seal baking uses steam to lock in juices, resulting in tender, succulent chicken with a balanced texture compared to traditional roasting methods.

Hybrid Roast-Infuse Technique

The Hybrid Roast-Infuse Technique combines dry heat roasting with periodic steam injection, enhancing moisture retention and achieving a tender, flavorful chicken crust. This method improves texture uniformity and reduces cooking time by utilizing steam to prevent drying while maintaining the Maillard reaction characteristic of traditional roasting.

Superheated Steam Roasting

Superheated steam roasting enhances chicken's juiciness and tenderness by combining dry heat roasting with steam above 100degC, accelerating Maillard reactions for a crispy, golden crust while preserving moisture. This method reduces cooking time compared to conventional roasting and minimizes nutrient loss, delivering flavorful, evenly cooked chicken with a healthier fat profile.

Wet-Roast Browning

Steam-assisted roasting enhances wet-roast browning in chicken by maintaining higher moisture levels, which promotes Maillard reaction while preventing skin from drying out. This method yields a juicier interior and evenly browned, crispy skin compared to traditional dry roasting, where moisture loss can limit uniform browning.

Juicelock Steam Roasting

Juicelock Steam Roasting preserves moisture in chicken by infusing steam during cooking, resulting in tender, juicier meat compared to traditional dry roasting methods. This technique minimizes moisture loss, enhances flavor retention, and reduces cooking time while maintaining a crisp skin.

Roasting vs Steam-Assisted Roasting for Chicken Infographic

cookingdiff.com

cookingdiff.com