Roasting bread in a traditional oven provides consistent, controlled heat that ensures even browning and a uniform crust. Wood-fired oven roasting infuses bread with a unique smoky flavor and achieves a higher, more intense heat, creating a distinctive crust texture and enhanced aroma. Choosing wood-fired oven roasting over conventional methods elevates the sensory experience by combining rustic charm with artisanal quality.

Table of Comparison

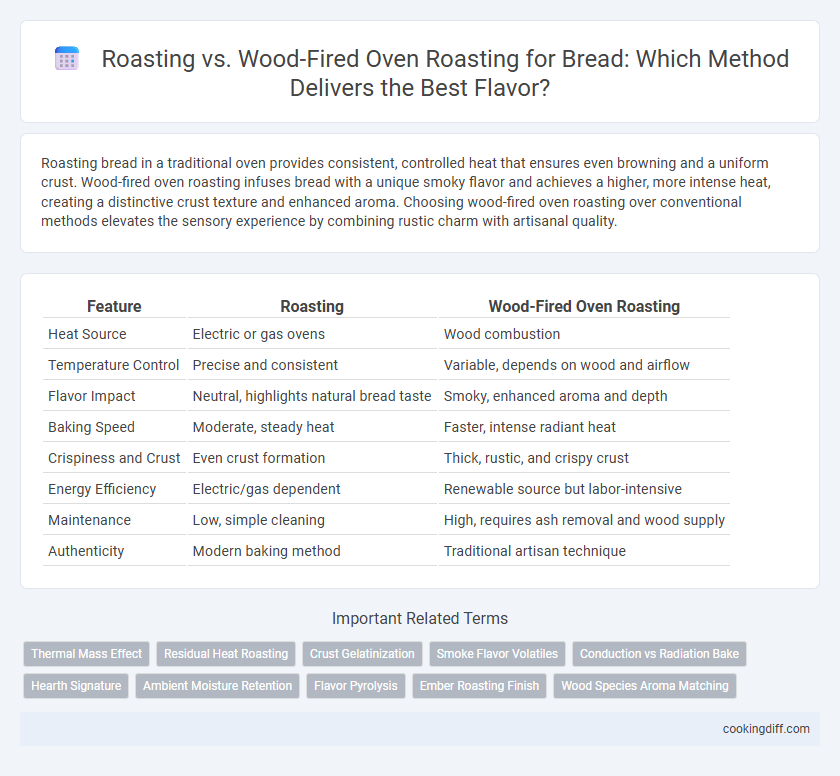

| Feature | Roasting | Wood-Fired Oven Roasting |

|---|---|---|

| Heat Source | Electric or gas ovens | Wood combustion |

| Temperature Control | Precise and consistent | Variable, depends on wood and airflow |

| Flavor Impact | Neutral, highlights natural bread taste | Smoky, enhanced aroma and depth |

| Baking Speed | Moderate, steady heat | Faster, intense radiant heat |

| Crispiness and Crust | Even crust formation | Thick, rustic, and crispy crust |

| Energy Efficiency | Electric/gas dependent | Renewable source but labor-intensive |

| Maintenance | Low, simple cleaning | High, requires ash removal and wood supply |

| Authenticity | Modern baking method | Traditional artisan technique |

Introduction to Bread Roasting Techniques

Roasting bread enhances its crust and aroma by exposing it to dry heat, a technique pivotal in achieving the perfect texture. Traditional roasting uses controlled oven temperatures to ensure even cooking and browning.

Wood-fired oven roasting infuses bread with a unique smoky flavor and crisp crust, leveraging high heat and radiant heat from the fire. This method requires skillful heat management to balance the intense environment for consistent results.

What is Traditional Roasting in Bread Making?

What is traditional roasting in bread making? Traditional roasting in bread making involves baking bread in a controlled dry heat environment, often using an oven to evenly cook the dough. This method contrasts with wood-fired oven roasting, which imparts a unique smoky flavor and creates a distinct crust texture due to the intense, uneven heat from burning wood.

How Wood-Fired Oven Roasting Works

Wood-fired oven roasting uses radiant heat from fire-heated bricks to cook bread evenly and develop a unique smoky flavor. This traditional method creates an intense, consistent heat environment that contrasts with conventional roasting techniques.

- Radiant Heat - The stone or brick surface absorbs and radiates heat, providing consistent oven temperatures crucial for perfect crust formation.

- Smoke Infusion - Burning wood releases aromatic compounds that permeate the bread, enhancing its flavor profile uniquely.

- Moisture Retention - The tightly sealed oven traps steam inside, promoting a moist crumb while maintaining a crispy crust.

Wood-fired oven roasting imparts distinctive qualities to bread that standard roasting methods cannot replicate.

Flavor Differences: Roasting vs Wood-Fired Oven

Roasting bread in a conventional oven provides consistent heat, resulting in a tender crumb and even browning. The controlled environment allows for precise temperature regulation, enhancing the Maillard reaction for a balanced crust flavor.

Wood-fired oven roasting infuses bread with smoky, earthy notes due to combustion gases and high radiant heat. This method creates a uniquely crispy crust with charred accents that are difficult to replicate in standard roasting ovens.

Crust Texture Comparison

Roasting bread develops a thick, caramelized crust with a slightly crisp texture due to direct heat exposure. Wood-fired oven roasting enhances the crust by infusing smoky flavors and creating a blistered, crunchy exterior from high, uneven temperatures. The intense heat from wood-fired ovens promotes oven spring, resulting in a crust that is both flavorful and structurally complex compared to conventional roasting methods.

Heat Distribution: Conventional vs Wood-Fired

Conventional roasting uses consistent, controlled heat through electric or gas ovens, ensuring even heat distribution around the bread. This stable environment helps achieve uniform crust development and precise baking times.

Wood-fired oven roasting relies on radiant heat from burning wood, producing variable heat zones that create a unique, artisanal crust texture. The uneven heat distribution can cause hotspots, requiring skillful management to avoid undercooked or burnt areas. This method enhances flavor complexity by infusing smoky notes into the bread's crust.

Baking Time and Efficiency

Roasting bread in a conventional oven offers consistent baking times typically ranging from 25 to 35 minutes, allowing for precise temperature control and efficient energy use. Wood-fired oven roasting can reduce baking time due to intense heat retention but requires skillful temperature management to maintain efficiency.

- Conventional Oven Baking Time - Usually requires 25-35 minutes to bake bread evenly at controlled temperatures.

- Wood-Fired Oven Heat Retention - Provides higher peak temperatures that can shorten baking times significantly.

- Energy Efficiency - Conventional ovens are more energy-efficient due to regulated heating cycles compared to the variable and intensive fuel consumption in wood-fired ovens.

Equipment and Skill Requirements

| Equipment Requirements | Roasting typically requires a conventional oven or roasting pan, which is widely available and easy to maintain, whereas wood-fired oven roasting demands a specialized brick or stone oven capable of reaching and sustaining high temperatures. |

| Skill Level | Standard roasting involves straightforward temperature control and timing that suits novice bakers, while wood-fired oven roasting requires expertise in managing fire intensity, heat distribution, and airflow to achieve optimal bread crust and texture. |

Health and Nutrition Impact

Roasting bread in a conventional oven allows for more precise temperature control, reducing the formation of harmful compounds like acrylamide compared to wood-fired oven roasting. Wood-fired oven roasting often reaches higher temperatures that can create a smokier flavor but may increase exposure to polycyclic aromatic hydrocarbons (PAHs), which pose health risks when consumed in excess. Nutritionally, both methods preserve the bread's essential nutrients, but conventional roasting is generally considered safer for minimizing potential chemical contaminants.

Related Important Terms

Thermal Mass Effect

Roasting bread in a wood-fired oven leverages the oven's high thermal mass, which retains and radiates consistent heat, resulting in even crust development and enhanced flavor complexity. In contrast, conventional roasting methods often lack this sustained thermal mass effect, leading to less uniform baking and variable crust texture.

Residual Heat Roasting

Residual heat roasting leverages the retained warmth within an oven after the primary heat source is turned off, allowing bread to bake gently and develop a deep, even crust without the risk of burning. Wood-fired oven roasting, while utilizing high initial temperatures, benefits from residual heat to maintain consistent baking conditions, enhancing flavor complexity and crust texture in artisan bread.

Crust Gelatinization

Roasting produces a distinct crust gelatinization by applying even, dry heat that caramelizes surface sugars and proteins, creating a thick, crunchy exterior. Wood-fired oven roasting enhances this effect with higher temperatures and radiant heat, promoting deeper Maillard reactions and a uniquely blistered, flavorful crust.

Smoke Flavor Volatiles

Roasting bread imparts a mild caramelized crust with subtle Maillard reaction flavors, while wood-fired oven roasting introduces complex smoke flavor volatiles such as guaiacol and syringol, enhancing the bread's aroma and depth. These phenolic compounds from wood combustion significantly contribute to the sensory profile, creating a distinct smoky character unattainable through conventional roasting methods.

Conduction vs Radiation Bake

Roasting bread using a traditional oven primarily relies on conduction, where heat transfers directly from the hot oven surfaces to the bread, resulting in a more even crust development. Wood-fired oven roasting utilizes radiation heat from the radiant fire and hot oven walls, creating intense, localized heat that enhances crust caramelization and imparts a unique smoky flavor.

Hearth Signature

Hearth Signature enhances bread roasting by combining precise temperature control with radiant heat, delivering consistent crust development and even crumb texture superior to traditional wood-fired oven roasting. Unlike wood-fired ovens, which rely on fluctuating heat and smoke infusion, Hearth Signature ensures repeatable results with optimal moisture retention and caramelization for artisanal bread.

Ambient Moisture Retention

Roasting bread in a wood-fired oven enhances ambient moisture retention, creating a humid environment that prevents the crust from drying out and promotes better oven spring. In contrast, conventional roasting methods often lack this natural humidity, resulting in a drier crust and reduced moisture content within the bread.

Flavor Pyrolysis

Roasting bread using traditional ovens relies on controlled heat to develop flavor through caramelization and Maillard reactions, while wood-fired oven roasting intensifies flavor pyrolsis by exposing bread to higher, uneven temperatures and smoke compounds, creating a distinctive smoky aroma and complex crust texture. The pyrolysis process in wood-fired ovens enhances phenolic compounds and volatile oils, resulting in a richer, deeper flavor profile compared to conventional roasting methods.

Ember Roasting Finish

Roasting bread using ember roasting enhances crust development by exposing the dough directly to glowing embers' radiant heat, creating a distinct smoky flavor and crispier texture compared to traditional wood-fired oven roasting. Ember roasting finish delivers a uniquely charred aroma and uneven caramelization, contributing to artisanal bread quality favored by sourdough enthusiasts.

Roasting vs Wood-Fired Oven Roasting for bread. Infographic

cookingdiff.com

cookingdiff.com