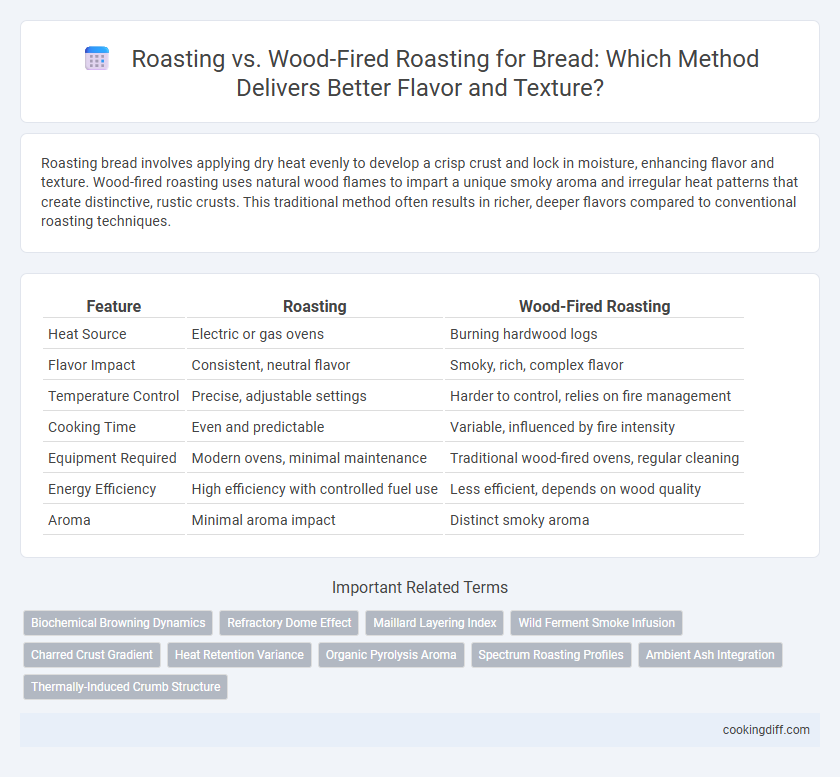

Roasting bread involves applying dry heat evenly to develop a crisp crust and lock in moisture, enhancing flavor and texture. Wood-fired roasting uses natural wood flames to impart a unique smoky aroma and irregular heat patterns that create distinctive, rustic crusts. This traditional method often results in richer, deeper flavors compared to conventional roasting techniques.

Table of Comparison

| Feature | Roasting | Wood-Fired Roasting |

|---|---|---|

| Heat Source | Electric or gas ovens | Burning hardwood logs |

| Flavor Impact | Consistent, neutral flavor | Smoky, rich, complex flavor |

| Temperature Control | Precise, adjustable settings | Harder to control, relies on fire management |

| Cooking Time | Even and predictable | Variable, influenced by fire intensity |

| Equipment Required | Modern ovens, minimal maintenance | Traditional wood-fired ovens, regular cleaning |

| Energy Efficiency | High efficiency with controlled fuel use | Less efficient, depends on wood quality |

| Aroma | Minimal aroma impact | Distinct smoky aroma |

Introduction to Roasting Methods in Bread Baking

Roasting in bread baking involves applying dry heat to develop a crust and enhance flavor through caramelization and Maillard reactions. Traditional roasting uses controlled oven temperatures, while wood-fired roasting relies on radiant heat from burning wood, imparting a distinct smoky aroma.

Oven roasting offers precise temperature control, ensuring consistent crumb texture and crust color in artisanal bread. Wood-fired roasting introduces natural variations in heat distribution, creating unique char patterns and subtle smoky notes that are prized in rustic loaves. Both methods impact the bread's final flavor profile and texture, catering to different baking styles and consumer preferences.

What is Traditional Roasting?

Traditional roasting involves cooking bread in a controlled oven environment using consistent heat sources such as gas or electric ovens. This method allows precise temperature regulation, ensuring even baking and predictable results.

- Consistent Heat Control - Traditional roasting uses modern ovens that maintain steady temperatures for uniform bread texture.

- Predictable Outcomes - The method enables bakers to replicate bread qualities by adjusting time and temperature settings accurately.

- Efficient Process - It simplifies baking by reducing reliance on manual heat management compared to wood-fired methods.

Understanding Wood-Fired Roasting

| Wood-fired roasting | Utilizes radiant heat from burning wood, creating uneven but flavorful temperature profiles essential for artisan bread textures. |

| Roasting | Conventional roasting typically applies consistent dry heat, often leading to uniform crust development but less smoky aroma compared to wood-fired methods. |

| Understanding Wood-Fired Roasting | Mastering wood-fired roasting requires controlling airflow and wood type to balance heat intensity and smoke infusion, key factors enhancing bread's crust complexity and depth of flavor. |

Heat Distribution: Conventional vs. Wood-Fired Ovens

Conventional ovens use electric or gas elements to provide consistent and even heat distribution around the bread, ensuring uniform roasting. Wood-fired ovens generate heat from burning wood, creating variable temperatures and fluctuating heat zones that can lead to uneven roasting but impart unique flavors.

- Conventional Ovens Heat Consistency - Utilizes controlled heating elements for precise temperature regulation and stable heat distribution.

- Wood-Fired Ovens Heat Variability - Wood combustion produces hotspots and cooler areas, resulting in diverse crust textures.

- Flavor Influence - Wood-fired roasting combines heat irregularities with smoky aromas, enhancing the bread's taste profile.

Flavor Profiles: Roasting vs. Wood-Fired Roasting

Roasting bread in a conventional oven produces a consistent, even flavor with subtle caramelization due to controlled heat distribution. This method emphasizes the natural sweetness and nuttiness of the grains without overpowering the bread's inherent taste.

Wood-fired roasting imparts a distinctive smoky aroma and complex flavor profile that enhances the crust's texture and depth. The variable heat and direct flame contact create unique charred notes and a rustic finish often prized by artisanal bakers.

Crust and Texture Differences

How do the crust and texture differ between roasting and wood-fired roasting for bread? Roasting typically produces a uniform crust with a softer interior, while wood-fired roasting creates a thicker, crunchier crust due to the intense, uneven heat. The smoky aroma and irregular heat distribution in wood-fired ovens enhance the bread's texture, resulting in a chewier crumb and more complex flavor profile.

Environmental Impact of Each Method

Roasting bread traditionally uses electric or gas ovens, which typically consume more fossil fuels and emit higher levels of carbon dioxide compared to wood-fired methods. Wood-fired roasting relies on renewable biomass, potentially lowering carbon footprint if sourced sustainably, but can contribute to air pollution through particulate emissions. Evaluating overall environmental impact requires considering energy efficiency, fuel source sustainability, and local air quality regulations for each roasting method.

Equipment and Setup Comparison

Roasting bread typically requires electric or gas ovens with precise temperature controls, allowing consistent heat distribution for even baking. Wood-fired roasting, by contrast, depends on traditional wood-fired ovens that use natural flames and embers, creating a unique smoky flavor but demanding more skill to manage temperature fluctuations. Equipment for wood-fired setups involves firewood storage, combustion chambers, and refractory materials, while modern roasting equipment emphasizes digital controls and insulated ovens for efficiency and reproducibility.

Skill Level and Learning Curve

Roasting bread requires a consistent temperature control that can be easily managed with modern ovens, making it more accessible for beginners. Wood-fired roasting demands advanced skills to regulate fire intensity and timing, presenting a steeper learning curve for bakers.

- Roasting skill level - Basic understanding of oven settings and timing is sufficient for quality results.

- Wood-fired roasting expertise - Requires mastery of fire manipulation and temperature fluctuations for optimal bread texture.

- Learning curve comparison - Conventional roasting offers a shorter learning curve, while wood-fired roasting necessitates extensive practice.

Choosing between roasting and wood-fired roasting depends on the baker's experience and willingness to invest time in mastering the craft.

Related Important Terms

Biochemical Browning Dynamics

Roasting bread induces Maillard reactions and caramelization, creating complex flavor compounds and a golden crust, while wood-fired roasting intensifies these biochemical browning dynamics through uneven heat and smoke exposure, enhancing aromatic profiles with phenolic and smoky compounds. The interplay of temperature gradients and combustion byproducts in wood-fired roasting accelerates melanoidin formation, contributing to deeper color and richer sensory characteristics compared to conventional roasting methods.

Refractory Dome Effect

Refractory dome effect in wood-fired roasting creates consistent, radiant heat by absorbing and slowly releasing thermal energy, enhancing crust development and crumb texture compared to traditional roasting. This thermal mass effect ensures uniform baking, reducing hotspots and improving bread's flavor complexity through precise temperature control.

Maillard Layering Index

Roasting bread using traditional methods versus wood-fired roasting significantly impacts the Maillard Layering Index, with wood-fired roasting enhancing complex flavor profiles due to higher, uneven heat distribution that promotes intensified Maillard reactions on the crust. This results in a deeper brown color and richer aromatic compounds, distinguishing wood-fired bread with a more robust, caramelized crust compared to conventional roasting techniques.

Wild Ferment Smoke Infusion

Wild ferment smoke infusion enhances wood-fired roasting by introducing complex microbial flavors and natural antioxidants that deepen the crust's texture and aroma, creating uniquely rustic bread profiles. Roasting with controlled heat offers consistency but lacks the organic, smoky nuances imparted by wild fermentation in wood-fired methods.

Charred Crust Gradient

Roasting bread typically produces an even, golden-brown crust with subtle Maillard reaction gradients, while wood-fired roasting creates a distinctive charred crust gradient due to the intense, uneven heat and smoky combustion gases. The wood-fired method enhances flavor complexity by imparting smoky notes and varying crust texture, from crisp charred edges to softer interior crumb.

Heat Retention Variance

Wood-fired roasting offers superior heat retention due to the thermal mass of bricks and stones that absorb and radiate heat evenly, maintaining steady temperatures crucial for crust development in bread. In contrast, conventional roasting methods often experience more significant heat fluctuations, impacting the consistency of the bake and potentially resulting in uneven texture and crumb.

Organic Pyrolysis Aroma

Roasting bread utilizes controlled heat to develop a uniform crust, enhancing flavor through Maillard reactions, while wood-fired roasting imparts a distinctive organic pyrolysis aroma from the combustion of natural wood, creating complex smoky and earthy undertones. This organic pyrolysis aroma arises from the thermal decomposition of lignin and cellulose in wood, enriching the bread's sensory profile with authentic, rustic notes that cannot be replicated by conventional roasting methods.

Spectrum Roasting Profiles

Spectrum roasting profiles reveal that traditional roasting offers precise temperature control for consistent crust development, while wood-fired roasting imparts unique smoky flavors and uneven heat distribution that enhances artisanal bread character. Analyzing spectrum profiles highlights how wood-fired methods create complex Maillard reactions and flavor compounds not achievable with conventional roasting techniques.

Ambient Ash Integration

Roasting bread over ambient ash enhances flavor complexity by infusing subtle smoky and earthy notes that ordinary roasting methods lack. Wood-fired roasting specifically leverages the natural combustion of wood, allowing ambient ash to interact directly with the dough, creating a unique crust texture and deeper aromatic profile.

Roasting vs Wood-Fired Roasting for bread. Infographic

cookingdiff.com

cookingdiff.com