An aluminum pan offers excellent heat conductivity, ensuring quick and even sauteing, while its lightweight design provides easy maneuverability. Ceramic-coated pans provide a non-stick surface that requires less oil and simplifies cleaning but may not distribute heat as uniformly as aluminum. Choosing between the two depends on prioritizing heat performance or ease of maintenance during sauteing.

Table of Comparison

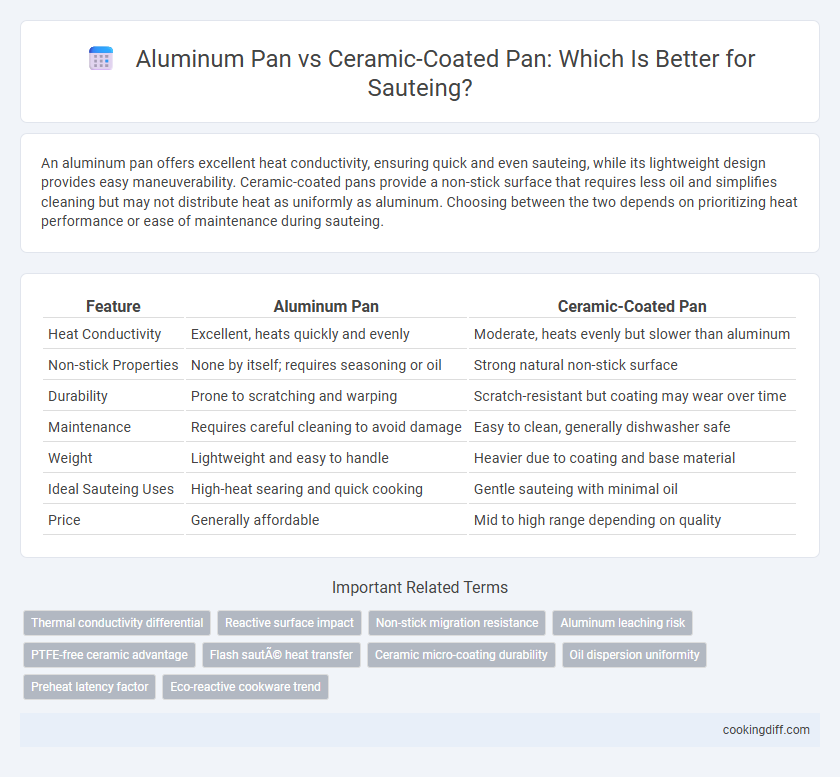

| Feature | Aluminum Pan | Ceramic-Coated Pan |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Moderate, heats evenly but slower than aluminum |

| Non-stick Properties | None by itself; requires seasoning or oil | Strong natural non-stick surface |

| Durability | Prone to scratching and warping | Scratch-resistant but coating may wear over time |

| Maintenance | Requires careful cleaning to avoid damage | Easy to clean, generally dishwasher safe |

| Weight | Lightweight and easy to handle | Heavier due to coating and base material |

| Ideal Sauteing Uses | High-heat searing and quick cooking | Gentle sauteing with minimal oil |

| Price | Generally affordable | Mid to high range depending on quality |

Introduction to Sautéing: Importance of the Right Pan

| The choice between aluminum and ceramic-coated pans significantly impacts sauteing performance, with aluminum offering superior heat conductivity for quick, even cooking, while ceramic-coated pans provide non-stick convenience and enhanced durability. |

| Aluminum pans heat rapidly and maintain consistent temperature, essential for the high-heat, fast-cooking technique of sauteing, whereas ceramic coatings reduce food adhesion, minimizing oil usage and easing cleanup. |

| Selecting the appropriate pan aligns with sauteing goals: aluminum pans optimize heat control and browning, whereas ceramic-coated options prioritize ease of use and health-conscious cooking with less fat. |

Aluminum Pans: Key Features for Sautéing

Aluminum pans are highly favored for sauteing due to their superior heat conductivity and lightweight nature, allowing for quick and even cooking. Their ability to respond rapidly to temperature changes ensures precise control over sauteing processes.

- Excellent Heat Conductivity - Aluminum pans distribute heat evenly across the surface, minimizing hot spots and promoting uniform cooking.

- Lightweight Construction - The low weight of aluminum pans allows for easy maneuverability when tossing or stirring ingredients during sauteing.

- Rapid Temperature Response - Aluminum quickly heats up and cools down, giving cooks tight control over browning and preventing overcooking.

Ceramic-Coated Pans: Unique Sautéing Qualities

Ceramic-coated pans offer superior non-stick properties that facilitate easy browning and deglazing during sauteing. Their even heat distribution prevents hot spots, ensuring consistent cooking results compared to aluminum pans.

- Non-stick surface - Allows food to release effortlessly, reducing the need for excess oil or butter.

- Heat retention - Maintains a uniform temperature which is ideal for precise sauteing of delicate ingredients.

- Chemical resistance - Resists high heat degradation and scratching better than traditional aluminum pans.

Heat Conductivity: Aluminum vs Ceramic-Coated Pans

Aluminum pans offer superior heat conductivity, allowing for rapid and even heat distribution essential for precise sauteing. This enables consistent browning and reduces the risk of hot spots that can burn food.

Ceramic-coated pans provide moderate heat conductivity but excel in non-stick properties, making them ideal for sauteing delicate ingredients. However, their heat distribution is less efficient compared to aluminum, potentially requiring higher cooking temperatures.

Nonstick Performance: Which Pan Excels for Sautéing?

Aluminum pans offer excellent heat conductivity but may require additional oil to prevent sticking during sauteing. Ceramic-coated pans provide a naturally nonstick surface that enhances ease of cooking and cleaning.

- Aluminum's Heat Responsiveness - Aluminum pans heat up quickly ensuring even cooking but often need more oil for effective nonstick results.

- Ceramic Coating Durability - Ceramic coatings maintain nonstick integrity over time, reducing food adhesion and facilitating cleanup.

- Health and Chemical Safety - Ceramic-coated pans avoid the use of PTFE and PFOA chemicals commonly found in traditional nonstick surfaces.

Ceramic-coated pans generally excel in nonstick performance for sauteing by combining easy release and chemical safety with adequate heat distribution.

Durability and Longevity: Aluminum vs Ceramic-Coated Options

Aluminum pans offer excellent heat conductivity but tend to scratch and warp over time, reducing their durability for sauteing. Ceramic-coated pans provide a non-stick surface that resists scratching and maintains structural integrity longer, enhancing longevity. Choosing ceramic-coated pans often results in better long-term performance and less frequent replacement in saute cooking.

Health and Safety Considerations When Sautéing

Aluminum pans are popular for sauteing due to their excellent heat conductivity but may pose health concerns if the surface is scratched, potentially leaching aluminum into food. Ceramic-coated pans offer a non-toxic, non-reactive surface that prevents metal leaching and withstands high heat without releasing harmful chemicals. Choosing ceramic-coated pans enhances safety by minimizing exposure to toxic metals and maintaining food purity during sauteing.

Ease of Cleaning: Low-Maintenance Sautéing Choices

Aluminum pans offer excellent heat conduction and are typically dishwasher safe, making them easier to clean after sauteing greasy or sticky foods. Their non-reactive surface also prevents food residue from bonding, reducing scrubbing time.

Ceramic-coated pans require gentle hand washing to preserve their nonstick surface, which can be more delicate but still relatively low-maintenance when properly cared for. The ceramic coating naturally resists food sticking, often allowing for quick rinsing without heavy boiling or soaking.

Price Comparison: Aluminum vs Ceramic-Coated Pans

Which offers better value for sauteing: aluminum pans or ceramic-coated pans? Aluminum pans are generally more affordable, providing efficient heat conduction and durability at a lower price point. Ceramic-coated pans tend to be pricier due to their non-stick properties and eco-friendly materials, but they require gentler care to maintain their coating and longevity.

Related Important Terms

Thermal conductivity differential

Aluminum pans offer superior thermal conductivity, heating up quickly and distributing heat evenly for consistent sauteing results. Ceramic-coated pans provide a non-stick surface but have lower thermal conductivity, which can result in slower, less uniform heat distribution during cooking.

Reactive surface impact

Aluminum pans can react with acidic foods during sauteing, potentially altering flavors and causing discoloration, while ceramic-coated pans provide a non-reactive surface that preserves the food's natural taste and appearance. This non-reactivity enhances flavor integrity and reduces the risk of metal leaching into meals when cooking with acidic ingredients.

Non-stick migration resistance

Aluminum pans offer excellent heat conduction but may suffer from non-stick coating migration when exposed to high heat during sauteing, potentially affecting food safety. Ceramic-coated pans provide superior resistance to non-stick migration, maintaining coating integrity and ensuring safer, healthier cooking at elevated temperatures.

Aluminum leaching risk

When sauteing, aluminum pans heat quickly and evenly but pose a risk of aluminum leaching into acidic foods, potentially impacting health and flavor. Ceramic-coated pans provide a non-reactive surface that prevents aluminum exposure, offering a safer option for cooking acidic ingredients while maintaining effective heat distribution.

PTFE-free ceramic advantage

Ceramic-coated pans offer a PTFE-free nonstick surface that provides safer sauteing by reducing the risk of toxic fumes and chemical leaching, unlike some aluminum pans coated with PTFE-based materials. The high heat resistance and even heat distribution of ceramic coatings ensure consistent cooking performance while maintaining a healthier cooking environment.

Flash sauté heat transfer

Aluminum pans excel in flash saute heat transfer due to their superior thermal conductivity, allowing rapid and even heating essential for quick cooking techniques. Ceramic-coated pans provide non-stick benefits but generally have lower heat transfer efficiency, resulting in slower temperature response during flash sauteing.

Ceramic micro-coating durability

Ceramic-coated pans offer superior durability compared to aluminum pans due to their enhanced resistance to scratches and high-temperature wear, maintaining a non-stick surface longer during sauteing. The ceramic micro-coating provides excellent heat distribution and chemical stability, ensuring prolonged performance without degrading or releasing harmful substances.

Oil dispersion uniformity

Aluminum pans offer excellent heat conduction that promotes consistent oil dispersion and even cooking during sauteing. In contrast, ceramic-coated pans provide a smoother surface that reduces oil pooling but may heat less evenly, potentially affecting uniform oil distribution.

Preheat latency factor

Aluminum pans exhibit rapid preheat latency, reaching optimal sauteing temperature quickly due to their high thermal conductivity. Ceramic-coated pans have slower preheat latency, requiring more time to evenly distribute heat but providing excellent non-stick performance once heated.

Aluminum pan vs ceramic-coated pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com