An aluminum pan offers excellent heat conductivity and rapid temperature changes, making it ideal for quick sauteing tasks where responsiveness is key. Copper core pans provide superior heat distribution and precise temperature control, allowing for even cooking and preventing hotspots when sauteing delicate ingredients. While aluminum pans are lightweight and affordable, copper core pans tend to be more durable and preferred by chefs seeking optimal cooking performance.

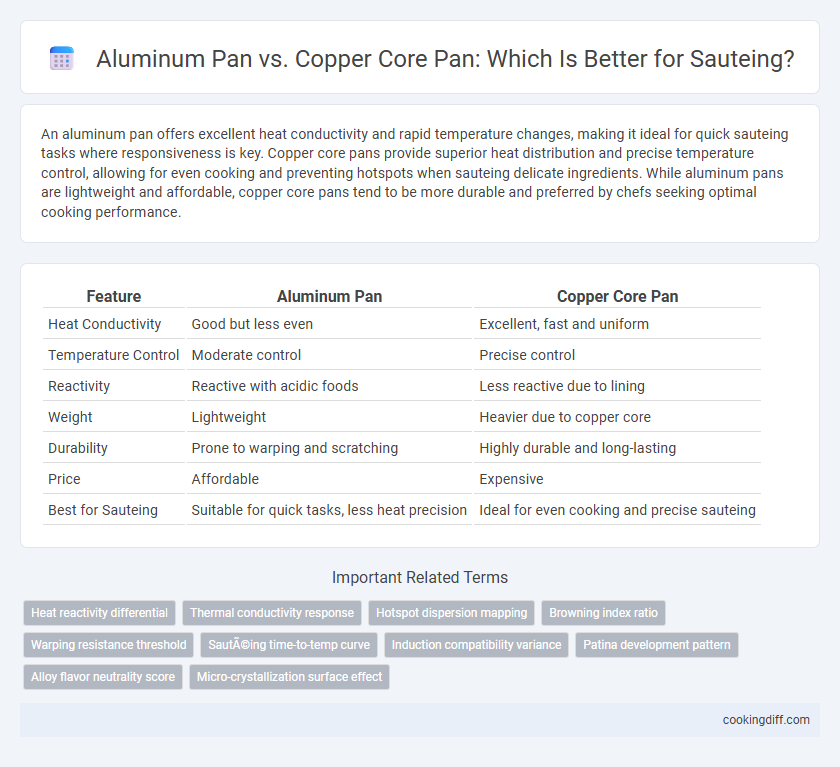

Table of Comparison

| Feature | Aluminum Pan | Copper Core Pan |

|---|---|---|

| Heat Conductivity | Good but less even | Excellent, fast and uniform |

| Temperature Control | Moderate control | Precise control |

| Reactivity | Reactive with acidic foods | Less reactive due to lining |

| Weight | Lightweight | Heavier due to copper core |

| Durability | Prone to warping and scratching | Highly durable and long-lasting |

| Price | Affordable | Expensive |

| Best for Sauteing | Suitable for quick tasks, less heat precision | Ideal for even cooking and precise sauteing |

Introduction to Sautéing: Choosing the Right Pan

| Aluminum Pan | Lightweight, excellent heat conduction, quick temperature adjustments, ideal for quick sauteing tasks. |

| Copper Core Pan | Superior heat distribution with precise temperature control, more durable with longer heat retention, preferred for delicate sauteing requiring consistent heat. |

| Sauteing Efficiency | Copper core pans maintain steady heat for even cooking, while aluminum pans offer rapid heating and cooling for versatility in sauteing techniques. |

Aluminum Pans: Key Features for Sautéing

Aluminum pans offer excellent heat conductivity, ensuring even cooking during sauteing. Their lightweight design provides ease of handling for quick, precise movements in the kitchen.

- Superior Heat Conduction - Aluminum efficiently distributes heat, preventing hot spots and promoting uniform sauteing.

- Lightweight Construction - Easy to maneuver, aluminum pans reduce wrist fatigue during extended cooking sessions.

- Affordability - Aluminum pans are generally more cost-effective compared to copper core options while delivering strong performance.

Copper Core Pans: Advantages in Sauté Techniques

Copper core pans offer superior heat conductivity, allowing precise temperature control essential for sauteing delicate ingredients. Their rapid heat responsiveness minimizes the risk of burning or uneven cooking, enhancing flavor and texture. This thermal efficiency supports quick, high-heat cooking, making copper core pans ideal for professional saute techniques.

Heat Conductivity: Aluminum vs Copper Core

Aluminum pans offer excellent heat conductivity, allowing for even heat distribution during sauteing, which helps prevent hot spots and burning. Copper core pans provide superior thermal responsiveness, enabling quick temperature adjustments that enhance precise cooking control.

Copper core pans heat up faster and cool down more rapidly than aluminum, making them ideal for delicate sauteing tasks requiring immediate temperature shifts. Aluminum pans are more affordable and lighter but may have slightly less precise heat regulation compared to copper core cookware. Both materials excel in heat conductivity, but copper core pans deliver unmatched performance for chefs prioritizing speed and accuracy in sauteing.

Temperature Control and Responsiveness

Aluminum pans heat quickly and evenly, providing good temperature control for sauteing, but they can react with acidic foods, affecting flavor. Copper core pans offer superior responsiveness to temperature changes, allowing precise heat adjustments that prevent burning or undercooking. This makes copper core pans ideal for delicate sauteing tasks where exact temperature management is crucial.

Weight and Maneuverability During Sautéing

Which pan offers better maneuverability for sauteing: aluminum or copper core? Aluminum pans are significantly lighter, making quick tosses and flips easier during cooking. Copper core pans, while heavier, provide excellent heat control but may require more effort to handle swiftly.

Durability and Maintenance Comparison

Aluminum pans offer good durability but tend to warp over time with high heat, requiring more careful maintenance. Copper core pans provide superior durability due to their robust construction and resist warping, though they demand regular polishing to maintain their appearance.

- Aluminum pan durability - Aluminum can warp or dent more easily under intense sauteing conditions.

- Copper core pan durability - Copper core pans maintain shape and structural integrity even at high temperatures.

- Maintenance demands - Aluminum pans are generally easier to clean but may lose nonstick qualities faster than copper core pans.

Copper core pans require more consistent upkeep but offer enhanced longevity compared to aluminum pans.

Flavor Impact: Do Pans Affect Taste?

Aluminum pans offer excellent heat conductivity, promoting even cooking that can enhance the natural flavors of sauteed ingredients without imparting metallic tastes. Copper core pans provide superior temperature control, allowing precise heat adjustments that preserve delicate flavors and prevent overcooking.

Copper's reactive nature can sometimes subtly influence taste, especially with acidic foods, while aluminum pans with anodized surfaces minimize this effect to maintain dish purity. Choosing between these pans depends on the desired flavor outcome and cooking technique, as both significantly shape the sauteing experience.

Price and Value: Aluminum vs Copper Core

Aluminum pans are generally more affordable, making them a budget-friendly option for sauteing without sacrificing decent heat conduction. Copper core pans, while pricier, offer superior temperature control and durability that often justify the higher investment in professional kitchens.

The value of aluminum pans lies in their lightweight design and efficient heat distribution, ideal for everyday cooking tasks. Copper core pans provide enhanced precision and responsiveness, delivering consistent saute results, which can be cost-effective over the long term due to their longevity.

Related Important Terms

Heat reactivity differential

Aluminum pans offer rapid, even heat distribution ideal for precise sauteing, while copper core pans provide superior thermal conductivity and faster temperature adjustments, enhancing control over cooking heat. The higher heat reactivity of copper reduces hotspots and allows for immediate response to stove adjustments, making it preferred for delicate saute tasks.

Thermal conductivity response

Copper core pans exhibit superior thermal conductivity, allowing for rapid and even heat distribution essential for precise sauteing control. Aluminum pans heat quickly but may deliver less consistent temperature regulation, potentially impacting the uniformity of sauteed ingredients.

Hotspot dispersion mapping

Aluminum pans provide even heat distribution but tend to develop hotspots more quickly compared to copper core pans, which offer superior thermal conductivity and consistent hotspot dispersion. Copper core pans minimize uneven cooking by rapidly equalizing temperature across the surface, making them ideal for precise sauteing techniques.

Browning index ratio

Copper core pans exhibit a superior browning index ratio compared to aluminum pans due to their enhanced heat conductivity and rapid temperature response, enabling more even and precise browning during sauteing. Aluminum pans, while lightweight and economical, often result in uneven heat distribution that can cause inconsistent browning and reduced Maillard reaction efficiency.

Warping resistance threshold

Copper core pans exhibit superior heat conductivity and maintain a more consistent temperature, reducing hotspots that contribute to warping during sauteing; aluminum pans, while lightweight and inexpensive, have a lower warping resistance threshold due to their softer metal composition. The durability of copper core pans against high heat and rapid temperature changes makes them ideal for sauteing tasks requiring frequent temperature adjustments.

Sautéing time-to-temp curve

Aluminum pans heat quickly and provide a rapid time-to-temp curve, ideal for fast sauteing with responsive temperature control. Copper core pans offer superior thermal conductivity and even heat distribution, resulting in precise temperature maintenance but a slightly slower heat-up time compared to aluminum.

Induction compatibility variance

Aluminum pans generally lack induction compatibility unless they feature a magnetic stainless steel base, while copper core pans often include an induction-friendly magnetic layer to ensure efficient heat distribution on induction cooktops. The variance in induction compatibility directly affects sauteing performance, with copper core pans providing superior temperature control and responsiveness compared to most aluminum pans without induction bases.

Patina development pattern

Aluminum pans develop a natural patina more slowly due to their reactive surface, which can affect the browning and flavor profile during sauteing, whereas copper core pans promote even heat distribution and faster patina formation, enhancing the Maillard reaction for superior flavor and texture. The copper core's superior thermal conductivity allows for precise temperature control, crucial for achieving consistent saute results and optimal patina development.

Alloy flavor neutrality score

Aluminum pans exhibit a high alloy flavor neutrality score, ensuring that sauteed ingredients retain their natural taste without any metallic or off-flavors. Copper core pans, while offering superior heat conductivity, sometimes impart subtle metallic notes, making aluminum pans preferable for flavor-sensitive sauteing.

Aluminum pan vs copper core pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com