Cast iron skillets offer superior heat retention and develop a natural non-stick surface with seasoning, making them ideal for high-heat sauteing and achieving a crisp, caramelized crust. Enameled cast iron pans provide even heat distribution and eliminate the need for seasoning, allowing for easier maintenance and preventing reactions with acidic ingredients during sauteing. Both options excel in heat performance, but cast iron skillets require regular seasoning, while enameled pans offer convenience with a smooth, durable surface.

Table of Comparison

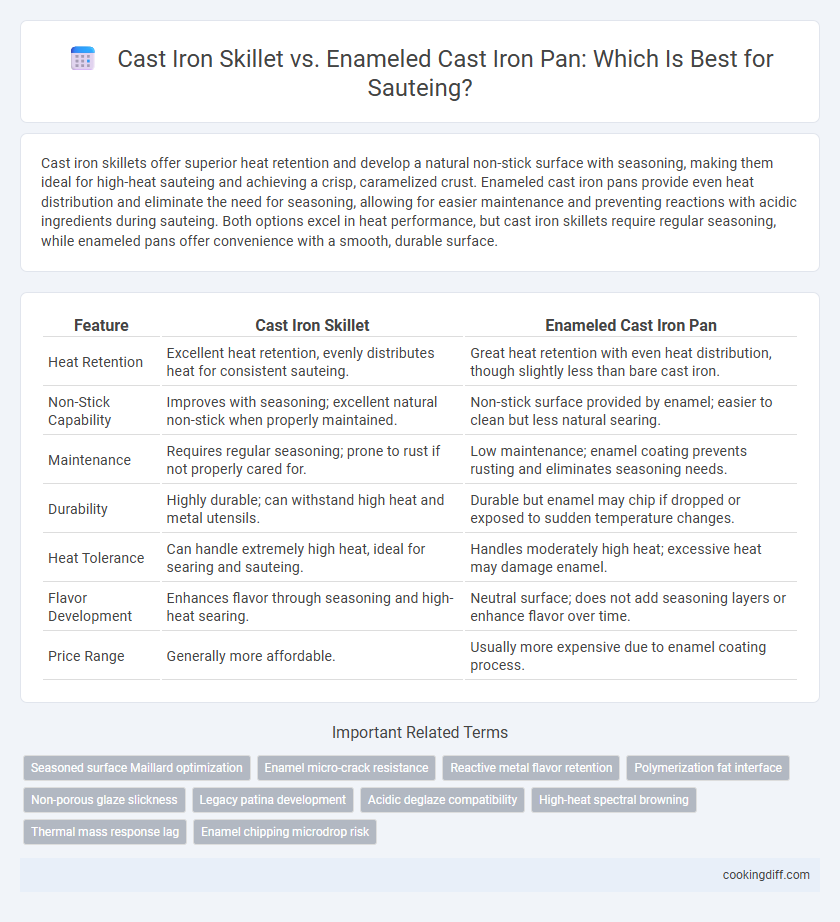

| Feature | Cast Iron Skillet | Enameled Cast Iron Pan |

|---|---|---|

| Heat Retention | Excellent heat retention, evenly distributes heat for consistent sauteing. | Great heat retention with even heat distribution, though slightly less than bare cast iron. |

| Non-Stick Capability | Improves with seasoning; excellent natural non-stick when properly maintained. | Non-stick surface provided by enamel; easier to clean but less natural searing. |

| Maintenance | Requires regular seasoning; prone to rust if not properly cared for. | Low maintenance; enamel coating prevents rusting and eliminates seasoning needs. |

| Durability | Highly durable; can withstand high heat and metal utensils. | Durable but enamel may chip if dropped or exposed to sudden temperature changes. |

| Heat Tolerance | Can handle extremely high heat, ideal for searing and sauteing. | Handles moderately high heat; excessive heat may damage enamel. |

| Flavor Development | Enhances flavor through seasoning and high-heat searing. | Neutral surface; does not add seasoning layers or enhance flavor over time. |

| Price Range | Generally more affordable. | Usually more expensive due to enamel coating process. |

Introduction to Sautéing: Choosing the Right Pan

Cast iron skillets provide excellent heat retention and develop a natural non-stick surface over time, making them ideal for high-heat sauteing. Enameled cast iron pans offer a smooth, easy-to-clean surface that prevents rusting and doesn't require seasoning, but they may heat less evenly. Selecting between these pans depends on heat tolerance, maintenance preference, and the specific sauteing technique used.

Cast Iron Skillet: Features and Sautéing Performance

Cast iron skillets are prized for their exceptional heat retention and even cooking surface, making them ideal for sauteing. Their natural non-stick seasoning improves with use, allowing for high-temperature searing and browning without sticking.

These skillets distribute heat uniformly, preventing hot spots that can cause uneven cooking. The heavy-duty construction offers durability and excellent heat control, essential for precision sauteing. Although they require regular seasoning and careful maintenance to prevent rust, cast iron skillets deliver superior performance in developing deep, rich flavors.

Enameled Cast Iron Pan: Features and Sautéing Performance

Enameled cast iron pans feature a smooth, non-reactive enamel coating that prevents food from sticking and eliminates the need for seasoning. This coating also allows for easy cleaning and resists acidic ingredients, making it ideal for sauteing a variety of dishes.

The even heat distribution and retention of enameled cast iron ensure consistent sauteing results with minimal hot spots. Its durability supports high-temperature cooking, preserving texture and flavor in vegetables and proteins without imparting metallic taste.

Heat Retention and Distribution Comparison

| Cookware Type | Heat Retention | Heat Distribution |

|---|---|---|

| Cast Iron Skillet | Excellent heat retention, maintains high temperatures for even cooking | Uneven initial heat distribution; requires preheating for consistent temperature |

| Enameled Cast Iron Pan | Strong heat retention with added protective enamel layer | More uniform heat distribution due to smooth enamel surface |

Nonstick Properties and Food Release

Cast iron skillets develop a natural nonstick surface over time through seasoning, which enhances food release during sauteing. Enameled cast iron pans feature a smooth, glass-like coating that resists sticking but may require more oil to prevent food from adhering. Both options provide excellent heat retention, but seasoned cast iron offers superior nonstick benefits for browning and searing ingredients effectively.

Maintenance and Cleaning Requirements

Cast iron skillets require seasoning and careful drying to prevent rust, making maintenance more intensive. Enameled cast iron pans have a protective coating that simplifies cleaning and eliminates the need for seasoning.

- Seasoning Needed - Cast iron skillets must be regularly seasoned to maintain a non-stick surface and prevent rust.

- Rust Prevention - Immediate drying after washing is essential for cast iron to avoid corrosion.

- Ease of Cleaning - Enameled cast iron pans can be cleaned with soap and water without risk of damaging the surface.

Durability and Longevity

Cast iron skillets are renowned for their exceptional durability, often lasting a lifetime when properly maintained. The seasoned surface in cast iron improves with use, enhancing its non-stick properties and resistance to wear over decades.

Enameled cast iron pans offer a protective coating that prevents rust and eliminates the need for seasoning, increasing longevity with less maintenance. However, the enamel can chip or crack under heavy impact, which may reduce the pan's lifespan compared to bare cast iron.

Weight and Handling in Sautéing

Cast iron skillets are heavier and require more effort to handle during sauteing, which can affect maneuverability. Enameled cast iron pans, while still substantial in weight, often feature smoother surfaces and ergonomic handles that improve grip and ease of use.

- Weight Impact - Cast iron skillets typically weigh between 5 to 12 pounds, making them sturdy but less agile for quick sauteing movements.

- Handling Comfort - Enameled cast iron pans include coated surfaces and larger handles that distribute weight more evenly for better control.

- Heat Distribution vs Weight - Both types offer excellent heat retention, but the heavier cast iron skillet may tire hands more quickly during prolonged sauteing.

Flavor Development: Seasoning vs. Enamel

Cast iron skillets develop a natural non-stick surface over time through seasoning, which enhances flavor by allowing a slight fond buildup during sauteing. Enameled cast iron pans, coated with a vitreous enamel layer, do not season but offer easy maintenance and prevent metallic taste transfer in dishes.

- Seasoning Enhances Flavor - The polymerized oil layer in seasoned cast iron imparts deeper, richer flavors through repeated cooking.

- Enamel Provides Neutral Taste - Enameled surfaces resist reactive compounds, preserving the pure taste of sauteed ingredients.

- Fond Formation vs. Easy Cleaning - Cast iron skillets create fond essential for flavor development, whereas enameled pans prioritize convenience without seasoning.

Choosing between seasoned cast iron and enameled cast iron pans depends on balancing flavor complexity with upkeep preferences.

Related Important Terms

Seasoned surface Maillard optimization

A cast iron skillet with a well-seasoned surface creates an optimal non-stick layer that enhances Maillard reaction development during sauteing, producing superior browning and flavor complexity. In contrast, enameled cast iron pans, lacking this seasoning, tend to have a less reactive surface, which can limit the depth of Maillard browning and slightly reduce flavor intensity.

Enamel micro-crack resistance

Enameled cast iron pans offer superior resistance to micro-cracks compared to traditional cast iron skillets, ensuring durability during high-heat sauteing. This resistance helps maintain a smooth cooking surface and prevents food from sticking, optimizing sauteing performance and pan longevity.

Reactive metal flavor retention

Cast iron skillets retain heat exceptionally well, promoting even browning and enhancing flavor through seasoning buildup, but their reactive surface can sometimes impart a metallic taste to acidic foods. Enameled cast iron pans, coated with a non-reactive glaze, prevent flavor alteration and preserve the true taste of sauteed ingredients while offering similar heat retention benefits.

Polymerization fat interface

Cast iron skillets develop a natural polymerized fat interface that enhances non-stick properties and flavor over time, whereas enameled cast iron pans lack this seasoning layer, resulting in a less effective polymerization surface for sauteing. The polymerization of fats in traditional cast iron improves heat retention and browning, making it superior for high-heat sauteing compared to the stable but less reactive enamel coating.

Non-porous glaze slickness

Enameled cast iron pans feature a durable, non-porous glaze that offers superior slickness, reducing food sticking and enhancing sauteing performance compared to traditional cast iron skillets, which have a porous surface requiring seasoning. The smooth enamel coating also prevents absorption of flavors and odors, ensuring easier cleaning and consistent cooking results.

Legacy patina development

Cast iron skillets develop a natural, seasoning-based legacy patina that enhances non-stick performance and flavor depth with continued use. Enameled cast iron pans, coated with a glass layer, prevent patina formation, offering easier maintenance but less seasoning evolution and flavor integration over time.

Acidic deglaze compatibility

Cast iron skillets excel in heat retention but can react with acidic ingredients during deglazing, potentially imparting a metallic taste and damaging the seasoning. Enameled cast iron pans offer superior compatibility with acidic deglazes, preventing metal interaction and providing easy cleanup while maintaining even heat distribution.

High-heat spectral browning

Cast iron skillets excel in high-heat spectral browning due to their superior heat retention and ability to reach higher temperatures, creating a rich Maillard reaction essential for sauteing. Enameled cast iron pans offer even heat distribution but typically have a lower heat ceiling, which can limit peak browning intensity.

Thermal mass response lag

Cast iron skillets possess high thermal mass leading to slower response to temperature changes, which helps maintain steady heat during sauteing but reduces precision with rapid heat adjustments. Enameled cast iron pans share similar heat retention properties but slightly improve response time due to their coated surface, offering a balance between heat stability and temperature control for sauteed dishes.

Cast iron skillet vs Enameled cast iron pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com