Enamel-coated pans provide excellent heat retention and durability, making them ideal for high-heat sauteing with even browning and minimal sticking. Ceramic nonstick pans offer a naturally nonstick surface that requires less oil, perfect for healthier cooking and easy cleanup, but they may not withstand very high temperatures as well as enamel-coated options. Choosing between the two depends on whether durability and heat retention or nonstick convenience and lower fat cooking are priorities in your sauteing technique.

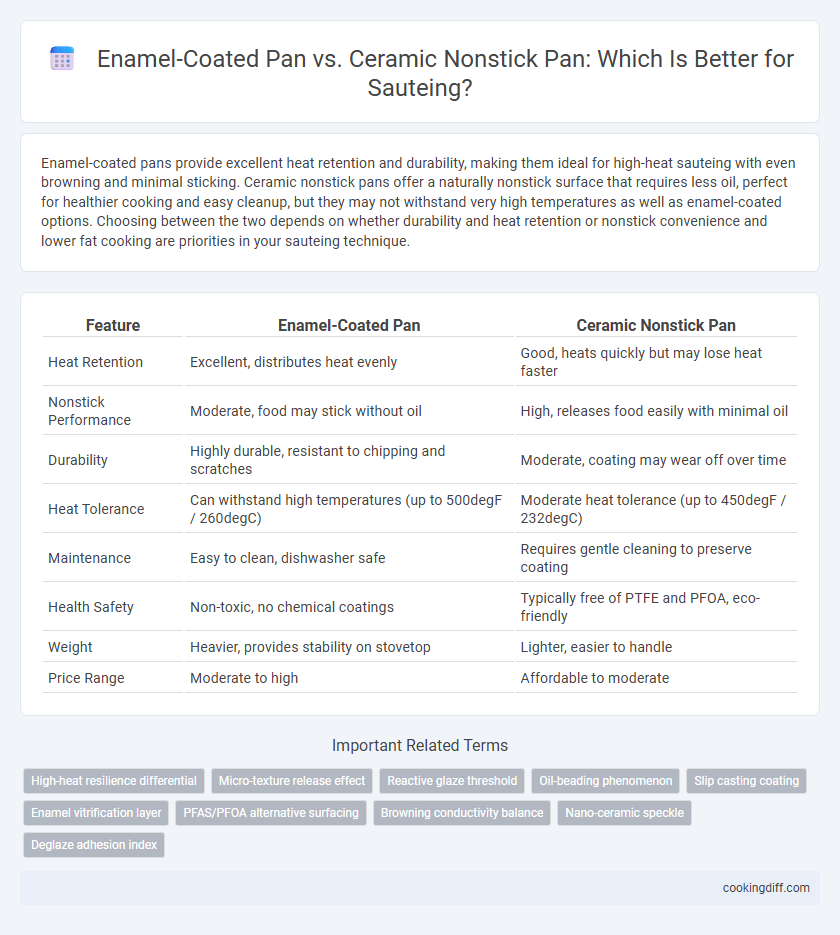

Table of Comparison

| Feature | Enamel-Coated Pan | Ceramic Nonstick Pan |

|---|---|---|

| Heat Retention | Excellent, distributes heat evenly | Good, heats quickly but may lose heat faster |

| Nonstick Performance | Moderate, food may stick without oil | High, releases food easily with minimal oil |

| Durability | Highly durable, resistant to chipping and scratches | Moderate, coating may wear off over time |

| Heat Tolerance | Can withstand high temperatures (up to 500degF / 260degC) | Moderate heat tolerance (up to 450degF / 232degC) |

| Maintenance | Easy to clean, dishwasher safe | Requires gentle cleaning to preserve coating |

| Health Safety | Non-toxic, no chemical coatings | Typically free of PTFE and PFOA, eco-friendly |

| Weight | Heavier, provides stability on stovetop | Lighter, easier to handle |

| Price Range | Moderate to high | Affordable to moderate |

Key Differences: Enamel-Coated vs Ceramic Nonstick Pans

Enamel-coated pans offer excellent heat retention and durability, making them ideal for high-heat sauteing, while ceramic nonstick pans provide superior nonstick performance with easier cleanup but may be less heat-tolerant. Both pan types avoid reactive metal surfaces, preserving food flavor and quality during sauteing.

- Heat Retention - Enamel-coated pans retain and distribute heat evenly, enabling consistent sauteing results at higher temperatures.

- Nonstick Properties - Ceramic nonstick pans feature a smooth surface that reduces food sticking, facilitating low-oil cooking and effortless cleanup.

- Durability - Enamel coatings are resistant to scratching and chipping under vigorous use, while ceramic coatings can wear down faster with metal utensils or abrasive cleaning.

Sautéing Performance: Heat Distribution and Retention

Enamel-coated pans offer excellent heat retention, allowing for consistent sauteing temperatures and even browning of ingredients. Their superior heat distribution prevents hot spots, ensuring food cooks evenly across the surface.

Ceramic nonstick pans heat up quickly but may have uneven heat distribution, which can lead to inconsistent sauteing results. Despite faster heat loss, ceramic coatings provide a smooth surface that requires less oil for sauteing delicate foods.

Food Release and Nonstick Qualities

Enamel-coated pans provide excellent food release due to their smooth, non-porous surface, which prevents food from sticking during sauteing. Their durable finish resists scratches and high heat, maintaining consistent nonstick qualities over time.

Ceramic nonstick pans offer superior slickness initially, allowing delicate foods to glide easily while sauteing without tearing. However, ceramic coatings may lose their nonstick effectiveness faster with frequent use and higher temperatures compared to enamel-coated pans.

Durability and Longevity in Daily Sautéing

Enamel-coated pans offer superior durability due to their resistance to chipping and high heat tolerance, making them ideal for daily sauteing tasks. Ceramic nonstick pans provide excellent nonstick performance but may wear down faster with frequent use and abrasive utensils. For longevity in daily sauteing, enamel-coated pans generally maintain their surface integrity longer, reducing the need for replacement.

Maintenance and Cleaning Ease

Enamel-coated pans offer a durable surface that resists staining and can be cleaned easily with mild detergents, making maintenance straightforward. They do not require seasoning and can often be placed in the dishwasher for added convenience.

Ceramic nonstick pans require gentle cleaning with non-abrasive sponges to preserve their coating and extend lifespan. Avoiding high heat and harsh cleaning agents is essential to prevent damage and maintain nonstick properties. Regular inspection for scratches ensures optimal performance during sauteing.

Health and Safety Considerations

Which pan ensures better health and safety when sauteing: enamel-coated or ceramic nonstick? Enamel-coated pans are free from toxic chemicals like PFOA and PTFE, making them a safer choice for high-heat cooking without risking harmful fumes. Ceramic nonstick pans are generally non-toxic but may wear down faster, potentially reducing their safety and effectiveness over time.

Flavor Development: Browning and Caramelization

Enamel-coated pans retain high heat efficiently, promoting superior browning and complex caramelization during sauteing. Ceramic nonstick pans offer even heat distribution but may not achieve the same Maillard reaction intensity, influencing flavor depth.

- Enamel-coated pans achieve higher surface temperatures - This enhances the Maillard reaction, key for rich, browned flavors.

- Ceramic nonstick pans provide gentle heat - They reduce the risk of burning but may produce milder caramelization.

- Flavor development depends on heat retention - Enamel pans excel in sustained high heat, facilitating deeper flavor complexity.

Compatibility with Cooktops and Ovens

Enamel-coated pans are highly compatible with all cooktops, including induction, gas, electric, and ceramic, and they can withstand high oven temperatures up to 500degF. Ceramic nonstick pans also work well on most cooktops but may have lower oven safety, typically around 350degF to 450degF, depending on the manufacturer. For sauteing, the enamel-coated pan offers greater versatility in heat sources and is more suitable for oven finishing techniques due to its higher heat tolerance.

Cost Comparison and Value for Money

Enamel-coated pans generally come at a higher price point but offer durable performance and aesthetic appeal, making them a long-term investment for sauteing. Ceramic nonstick pans are more affordable, providing good heat distribution and easy cleanup, though they may wear out faster with regular use.

- Enamel-Coated Pan Cost - Higher initial cost reflects durability and resistance to scratching.

- Ceramic Nonstick Pan Cost - Lower upfront cost appeals to budget-conscious buyers seeking decent sauteing performance.

- Value for Money - Enamel offers greater longevity while ceramic provides short-term affordability.

Choosing between these pans depends on balancing budget constraints with expected usage frequency and performance needs.

Related Important Terms

High-heat resilience differential

Enamel-coated pans withstand high heat better than ceramic nonstick pans, retaining their durability and preventing coating degradation during sauteing at elevated temperatures. Ceramic nonstick pans are more prone to damage and decreased nonstick performance when exposed to prolonged high heat, making enamel-coated pans a superior choice for intense sauteing.

Micro-texture release effect

Enamel-coated pans feature a slightly rough micro-texture that enhances the release of food during sauteing by creating tiny air pockets, reducing sticking and promoting even browning. Ceramic nonstick pans possess a smoother surface with a distinct micro-texture designed to prevent food adhesion through a durable polymer coating, optimizing ease of food release and cleanup while maintaining high-heat resistance.

Reactive glaze threshold

Enamel-coated pans feature a non-reactive glaze that withstands high sauteing temperatures without leaching metals or altering food flavors, making them ideal for acidic ingredients. Ceramic nonstick pans possess a reactive glaze threshold that can degrade faster under intense heat, potentially releasing compounds and compromising sauteing performance over time.

Oil-beading phenomenon

Enamel-coated pans exhibit minimal oil-beading, promoting even heat distribution and uniform sauteing, while ceramic nonstick pans often show pronounced oil-beading, causing uneven cooking and potential hot spots. The oil-beading phenomenon affects how ingredients contact the pan surface, impacting browning and moisture retention during sauteing.

Slip casting coating

Enamel-coated pans with slip casting coating provide a durable, chip-resistant surface ideal for high-heat sauteing, preserving both flavor and pan integrity. Ceramic nonstick pans offer smooth release properties but may wear faster under intense heat, making enamel-coated options preferable for long-lasting performance in sauteing.

Enamel vitrification layer

The enamel-coated pan features a vitrification layer that offers superior durability and resistance to high heat, making it ideal for evenly sauteing without warping or scratching. Unlike ceramic nonstick pans, the enamel vitrification maintains its smooth surface longer, ensuring consistent food release and enhanced flavor development during sauteing.

PFAS/PFOA alternative surfacing

Enamel-coated pans offer a durable, PFAS/PFOA-free surface ideal for high-heat sauteing without chemical leaching, while ceramic nonstick pans provide a naturally nonreactive, toxin-free alternative with superior food release properties but may require gentler handling to maintain coating integrity. Both surfaces prioritize health-conscious cooking by eliminating harmful fluorinated compounds, making them safer choices for sauteing compared to traditional nonstick options.

Browning conductivity balance

Enamel-coated pans provide superior browning due to their excellent heat conductivity and ability to maintain consistent high temperatures, essential for achieving a perfect Maillard reaction during sauteing. Ceramic nonstick pans offer moderate heat retention and even distribution but may require lower temperatures to preserve the coating, resulting in less intense browning compared to enamel-coated cookware.

Nano-ceramic speckle

Nano-ceramic speckle coatings in ceramic nonstick pans provide superior heat distribution and chemical resistance, enhancing the sauteing process by ensuring even cooking and easy food release. Enamel-coated pans, while durable and resistant to acidic ingredients, lack the advanced nonstick properties and quick heat response offered by nano-ceramic speckle technology.

Enamel-coated pan vs ceramic nonstick pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com