Sauteing uses direct contact with a hot pan, relying on conductive heat to quickly cook food while preserving texture and flavor. Infrared pan searing employs radiant heat that penetrates food surface layers more evenly, creating a distinct crust without overcooking the interior. This difference makes infrared searing ideal for achieving a uniform, caramelized exterior compared to the traditional saute method.

Table of Comparison

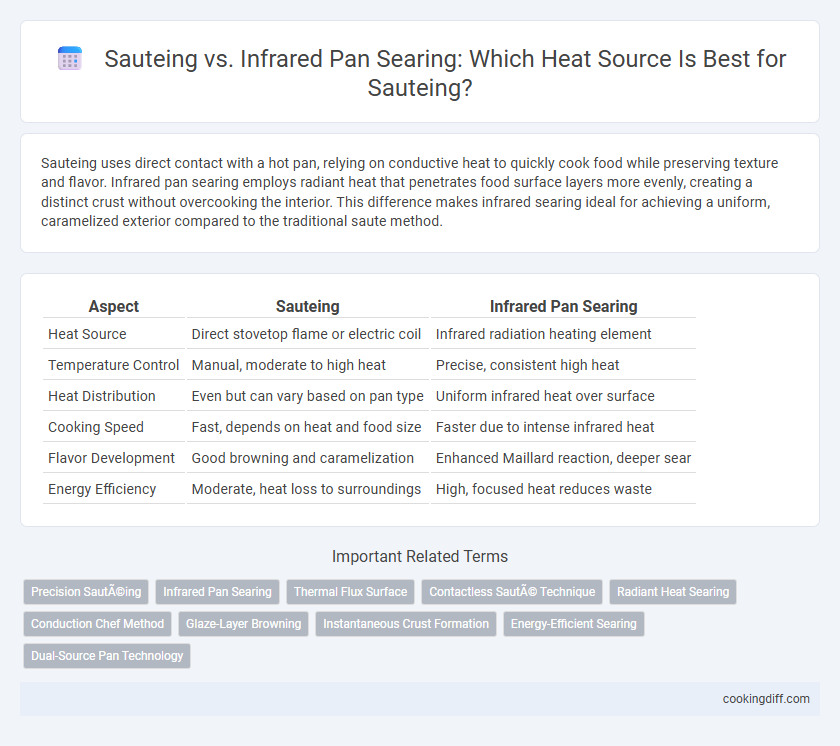

| Aspect | Sauteing | Infrared Pan Searing |

|---|---|---|

| Heat Source | Direct stovetop flame or electric coil | Infrared radiation heating element |

| Temperature Control | Manual, moderate to high heat | Precise, consistent high heat |

| Heat Distribution | Even but can vary based on pan type | Uniform infrared heat over surface |

| Cooking Speed | Fast, depends on heat and food size | Faster due to intense infrared heat |

| Flavor Development | Good browning and caramelization | Enhanced Maillard reaction, deeper sear |

| Energy Efficiency | Moderate, heat loss to surroundings | High, focused heat reduces waste |

Introduction to Sautéing and Infrared Pan Searing

Sauteing involves cooking food quickly in a small amount of oil or fat over medium-high heat, using direct contact with a hot pan. Infrared pan searing employs infrared radiation to deliver intense, even heat for rapid browning and caramelization without excessive oil.

Both techniques aim to develop flavor through Maillard reaction, but infrared pan searing offers more precise temperature control and faster heat transfer. Sauteing typically relies on gas or electric stovetops, creating slightly uneven heat distribution compared to the consistent infrared heat source. Infrared searing reduces cooking time and enhances crust formation on meats and vegetables, making it ideal for quick, high-heat applications.

Understanding the Science of Sautéing

Sauteing relies on direct contact with a hot pan surface to quickly cook food using conduction, while infrared pan searing employs radiant heat to achieve higher temperatures with less surface contact. Understanding the science of sauteing highlights the importance of radiant versus conductive heat transfer in influencing texture and flavor development.

- Sauteing uses conduction heat transfer - This method requires a heated pan to directly transfer heat to the food's surface for rapid cooking.

- Infrared pan searing uses radiant heat - Infrared radiation heats food by emitting energy waves, enhancing browning and crust formation without extensive oil use.

- Heat source affects Maillard reaction - The temperature control and heat distribution differences between methods determine the extent of flavor complexity achieved.

What is Infrared Pan Searing?

Infrared pan searing uses infrared radiation to generate intense, even heat directly on the cooking surface, allowing for precise temperature control and rapid browning of meats and vegetables. Unlike traditional sauteing, which relies on conduction heat through a hot pan, infrared searing reduces flare-ups and produces a consistent crust without overcooking the interior.

This method enhances Maillard reaction efficiency, resulting in enhanced flavor and texture development. Infrared pan searing is particularly effective for thicker cuts of meat, ensuring a caramelized exterior while preserving juiciness inside.

Heat Distribution: Sautéing vs Infrared Pan Searing

How does heat distribution differ between sauteing and infrared pan searing? Sauteing uses direct contact with a hot surface, promoting even heat spread across the pan for consistent cooking. Infrared pan searing relies on radiant heat, delivering rapid, intense heat that concentrates on the surface of the food for a faster, more precise sear.

Flavor Development: Comparing Sautéing and Infrared Techniques

Sauteing utilizes direct contact with a hot pan to develop rich, caramelized flavors through the Maillard reaction, enhancing the natural taste of ingredients. Infrared pan searing provides intense, even heat that creates a superior crust and deeper flavor complexity by rapidly sealing in juices. Both techniques maximize flavor development, but infrared searing excels in achieving a consistent, restaurant-quality sear that intensifies umami notes.

Cooking Speed: Sautéing vs Infrared Pan Searing

Sauteing uses direct contact with a hot pan to cook food quickly over medium to high heat, promoting even browning and moisture retention. Infrared pan searing relies on intense radiant heat, significantly accelerating cooking speed and enhancing the Maillard reaction for a superior crust.

- Sauteing offers controlled heat - it allows quick cooking with less risk of burning due to moderate temperature ranges.

- Infrared pan searing achieves higher temperatures rapidly - it significantly reduces overall cooking time by delivering precise and intense heat.

- Infrared technology enhances surface caramelization - improving flavor and texture in a shorter cooking period compared to traditional sauteing.

Both methods optimize cooking speed but infrared pan searing excels in maximizing heat intensity and reducing time.

Nutrient Retention: Which Method Wins?

Sauteing preserves more water-soluble vitamins like vitamin C and B-complex due to its moderate heat and shorter cooking time compared to infrared pan searing. Infrared pan searing, while providing intense and even heat, can lead to higher nutrient degradation because of the elevated temperatures used. For optimal nutrient retention, sauteing offers a gentler cooking process that maintains the integrity of sensitive nutrients better than infrared pan searing.

Equipment and Tools Needed for Each Method

| Method | Equipment Needed | Tools Required |

|---|---|---|

| Sauteing | Stainless steel, cast iron, or non-stick skillet heated over a gas or electric stovetop burner | Metal or wooden spatula, tongs, and cooking oil with a high smoke point |

| Infrared Pan Searing | Specialized infrared heating element or infrared burner paired with a cast iron or carbon steel pan | Heat-resistant gloves, metal spatula or tongs designed for high-heat, and thermometer for precise temperature control |

Ideal Foods for Sautéing vs Infrared Pan Searing

Sauteing is ideal for delicate foods like vegetables, thin cuts of meat, and seafood, where quick, even cooking at medium to high heat preserves texture and moisture. Infrared pan searing excels with thicker cuts of meat, such as steaks and pork chops, as it delivers intense, rapid heat for a crispy crust and deeper Maillard reaction.

Vegetables, shrimp, and chicken breasts benefit from sauteing's controlled heat and frequent stirring, preventing burning and promoting even browning. Infrared searing is best suited for foods requiring a robust crust without overcooking the interior, including ribeye steaks and lamb chops due to its precise and concentrated heat source.

Related Important Terms

Precision Sautéing

Precision sauteing uses controlled stovetop heat to evenly cook food with minimal oil, preserving texture and flavor. Infrared pan searing offers higher temperatures but less temperature control, making precision sauteing ideal for delicate ingredients requiring consistent heat distribution.

Infrared Pan Searing

Infrared pan searing delivers intense, even heat that penetrates food quickly, creating a superior Maillard reaction compared to traditional sauteing methods. This precise heat control reduces cooking time and enhances flavor development by maintaining consistent surface temperatures without the risk of flare-ups.

Thermal Flux Surface

Sauteing relies on direct contact with a hot pan surface, achieving a moderate thermal flux surface that ensures even cooking and browning of ingredients. Infrared pan searing generates a higher and more concentrated thermal flux surface, resulting in faster Maillard reactions and a crisper crust without overcooking the interior.

Contactless Sauté Technique

Infrared pan searing uses radiant heat to cook food evenly without direct contact, enhancing Maillard reaction and flavor development while reducing oil usage and sticking. Contactless saute techniques leverage infrared heat sources to achieve precise temperature control and faster cooking times compared to traditional sauteing that relies on direct pan-to-food contact.

Radiant Heat Searing

Radiant heat searing in infrared pan searing delivers intense, evenly distributed heat that rapidly caramelizes the food's surface, creating a superior Maillard reaction compared to traditional sauteing methods. Unlike sauteing, which relies on direct contact with a hot pan, infrared searing uses radiant heat to penetrate the food for a crisp exterior while retaining juiciness inside.

Conduction Chef Method

Sauteing relies on direct conduction heat transfer from a hot pan to food, allowing precise temperature control and even cooking essential for delicate ingredients. Infrared pan searing uses radiant heat, which can create intense surface temperatures but lacks the even conduction necessary for consistent sauteing results preferred by professional chefs.

Glaze-Layer Browning

Sauteing relies on direct contact with a hot pan, generating Maillard reaction-based glaze-layer browning through oil heat transfer, while infrared pan searing uses radiant heat to create a more even and intense glaze-layer browning with minimal moisture loss. Infrared pan searing achieves higher surface temperatures quickly, enhancing caramelization and producing a crispier, richer glaze compared to traditional sauteing.

Instantaneous Crust Formation

Sauteing relies on direct contact with a hot pan to create a crispy exterior through Maillard reactions, while infrared pan searing uses intense radiant heat to achieve instantaneous crust formation with minimal moisture loss. Infrared heat penetrates the food surface rapidly, resulting in a faster and more even crust compared to traditional sauteing methods.

Energy-Efficient Searing

Sauteing typically uses direct contact with a hot pan and moderate heat, making it energy-efficient for quick cooking by minimizing heat loss. Infrared pan searing employs radiant heat that penetrates food rapidly, offering higher temperatures faster and reducing overall cooking time, thereby improving energy efficiency in searing processes.

Sautéing vs Infrared Pan Searing for heat source. Infographic

cookingdiff.com

cookingdiff.com