Sauteing involves quickly cooking food in a small amount of oil over high heat to develop rich flavors and crisp textures. Nitrogen sauteing, on the other hand, uses liquid nitrogen to rapidly freeze ingredients mid-cook, creating unique, innovative textures that contrast with traditional sauteed elements. This technique enhances the sensory experience by combining hot and cold sensations, offering chefs new creative possibilities.

Table of Comparison

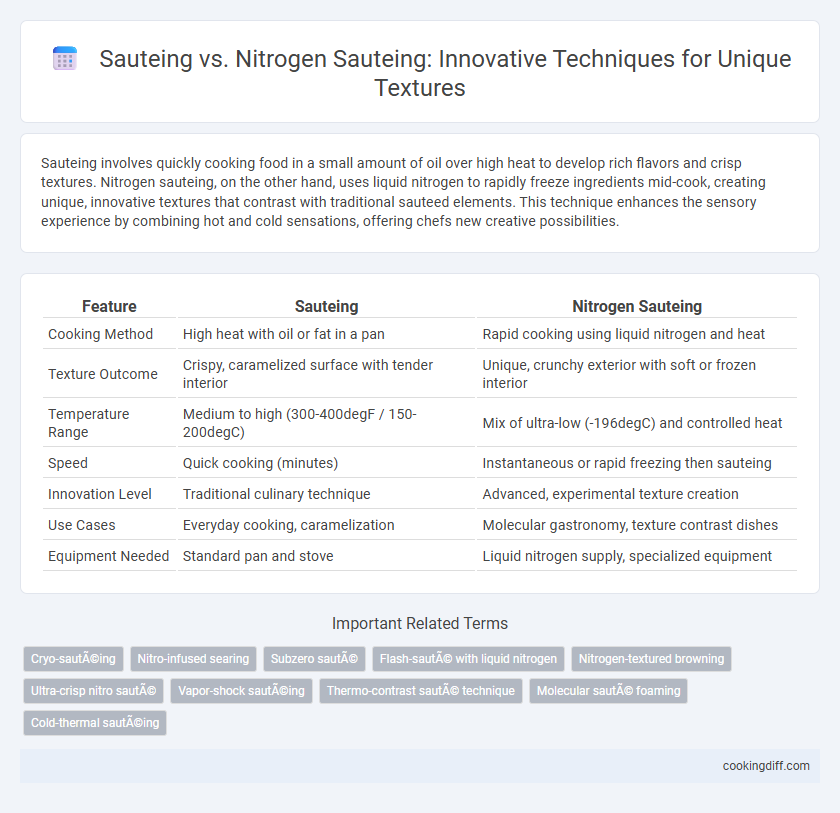

| Feature | Sauteing | Nitrogen Sauteing |

|---|---|---|

| Cooking Method | High heat with oil or fat in a pan | Rapid cooking using liquid nitrogen and heat |

| Texture Outcome | Crispy, caramelized surface with tender interior | Unique, crunchy exterior with soft or frozen interior |

| Temperature Range | Medium to high (300-400degF / 150-200degC) | Mix of ultra-low (-196degC) and controlled heat |

| Speed | Quick cooking (minutes) | Instantaneous or rapid freezing then sauteing |

| Innovation Level | Traditional culinary technique | Advanced, experimental texture creation |

| Use Cases | Everyday cooking, caramelization | Molecular gastronomy, texture contrast dishes |

| Equipment Needed | Standard pan and stove | Liquid nitrogen supply, specialized equipment |

Introduction to Sautéing: Classic Technique Overview

What distinguishes classic sauteing from nitrogen sauteing in texture creation? Classic sauteing involves cooking food quickly in a small amount of oil over high heat to achieve a browned, flavorful exterior and tender interior. Nitrogen sauteing innovates by incorporating liquid nitrogen, which freezes and crisps ingredients rapidly, producing unique textures unattainable with traditional methods.

What is Nitrogen Sautéing?

Nitrogen sauteing uses liquid nitrogen to rapidly chill and crisp ingredients during the cooking process, creating unique textures. This innovative technique contrasts traditional sauteing by integrating extreme cold to enhance the sensory experience.

- Rapid cooling effect - Liquid nitrogen freezes the surface of ingredients quickly, producing a distinctive crunch.

- Texture innovation - Combines heat and cold to create contrasting textures not achievable by conventional sauteing.

- Flavor preservation - The instant cold shock helps retain fresh flavors and nutrients in the food.

Comparing Heat Sources: Conventional vs Cryogenic

Sauteing utilizes conventional heat sources such as gas or electric stovetops, producing temperatures typically between 320degF and 500degF to quickly cook and brown food with direct heat. This dry-heat method enhances flavor development through Maillard reactions, resulting in crispy textures and rich aromas.

Nitrogen sauteing employs cryogenic cooling with liquid nitrogen to rapidly freeze and simultaneously cook, offering highly innovative textures by controlling moisture retention and temperature gradients. The cryogenic technique minimizes thermal degradation and provides unique mouthfeels not achievable with traditional sauteing.

Texture Development: Traditional vs Nitrogen Methods

Sauteing traditionally uses high heat and oil to develop rich, caramelized textures through Maillard reactions, enhancing flavor and surface crispiness. Nitrogen sauteing leverages cryogenic rapid cooling combined with sauteing to create unique, delicate textures by controlling moisture retention and cellular structure.

- Traditional Sauteing Texture Development - High heat promotes browning and a crispy exterior while maintaining a tender interior.

- Nitrogen Sauteing Technique - Rapid freezing with liquid nitrogen preserves moisture, resulting in innovative, contrasting textures.

- Texture Control - Nitrogen methods enable chefs to manipulate texture gradients inaccessible by conventional sauteing.

Integrating nitrogen sauteing with traditional methods expands culinary creativity by delivering unprecedented mouthfeel experiences.

Flavor Impact in Sautéing and Nitrogen Sautéing

Sauteing develops deep, caramelized flavors through high-heat cooking, enhancing the natural sugars and creating complex taste profiles. Nitrogen sauteing, by incorporating liquid nitrogen, rapidly freezes and shatters ingredients, preserving fresh, intense flavors with contrasting textures. This innovative method intensifies the flavor impact by balancing hot, cooked notes with cold, crisp sensations, offering a unique gustatory experience.

Innovative Textures: Culinary Possibilities Explored

Sauteing utilizes high heat and quick cooking techniques to develop rich, caramelized textures, enhancing flavor complexity in culinary creations. Nitrogen sauteing introduces cryogenic methods that rapidly freeze ingredients, allowing chefs to experiment with contrasting textures and preserve vibrant colors effectively.

Innovative textures arise from combining traditional sauteing's Maillard reaction with nitrogen's freezing properties, creating unique mouthfeels and visual appeal. Chefs can craft dishes with crisp exteriors and unexpectedly tender interiors by manipulating temperature gradients. This fusion expands the culinary possibilities, pushing the boundaries of texture innovation in modern gastronomy.

Equipment and Safety Considerations

| Equipment | Sauteing requires a heavy-bottomed skillet or saute pan, preferably stainless steel or cast iron, heated over medium-high heat. Nitrogen sauteing utilizes specialized cryogenic equipment capable of handling liquid nitrogen, including insulated gloves and containers designed to withstand extreme cold. |

| Safety Considerations | Traditional sauteing demands caution regarding hot oil splatters and high temperatures; wearing heat-resistant gloves and using appropriate utensils prevents burns. Nitrogen sauteing mandates rigorous safety protocols due to the risks of cold burns and asphyxiation; proper ventilation, protective gear, and training are essential to safely create innovative textures. |

Applications in Modern Gastronomy

Sauteing remains a fundamental technique in modern gastronomy for developing rich flavors and crisp textures through high-heat cooking. In contrast, nitrogen sauteing employs liquid nitrogen to rapidly cool and crisp ingredients post-saute, creating innovative textures not achievable with traditional methods.

Chefs use nitrogen sauteing to produce unique mouthfeels, such as ultra-crispy exteriors and frozen interiors, enhancing sensory experiences in avant-garde dishes. This fusion of thermal and cryogenic techniques expands the textural palette available in contemporary culinary applications.

Pros and Cons: Sautéing vs Nitrogen Sautéing

Traditional sauteing enhances flavors with direct heat and caramelization, while nitrogen sauteing offers innovative textures by rapidly freezing and cooking simultaneously. Each method presents unique advantages and limitations in culinary applications.

- Traditional sauteing excels in flavor development - It uses high heat to create caramelized surfaces that enhance taste and aroma.

- Nitrogen sauteing allows for novel textures - Liquid nitrogen rapidly freezes ingredients, preserving structure and creating contrast in mouthfeel.

- Limitations exist with both techniques - Traditional sauteing lacks textural innovation, whereas nitrogen sauteing requires specialized equipment and safety precautions.

Related Important Terms

Cryo-sautéing

Cryo-sauteing combines traditional sauteing techniques with cryogenic nitrogen to rapidly freeze ingredients mid-cook, creating unique textures unattainable through conventional methods. This innovative approach enhances flavor retention and texture contrast by instantly locking in moisture and structure, revolutionizing culinary experiences.

Nitro-infused searing

Nitrogen sauteing leverages liquid nitrogen's rapid freezing to create unique textures by searing foods instantly, preserving moisture while enhancing surface crispness. Nitro-infused searing introduces innovative culinary techniques that combine high-heat sauteing with nitrogen's chilling properties, producing unparalleled crispness and a tender interior.

Subzero sauté

Subzero saute employs liquid nitrogen to rapidly freeze ingredients during the sauteing process, resulting in uniquely crisp textures and intense flavor preservation unattainable with traditional sauteing. This innovative technique enhances mouthfeel by creating a contrast between the cold, crunchy exterior and tender interior, revolutionizing texture profiles in modern cuisine.

Flash-sauté with liquid nitrogen

Flash-saute with liquid nitrogen combines the rapid heat of traditional sauteing with the ultra-cold properties of nitrogen to create innovative textures by instantly freezing and shock-cooking ingredients, preserving crispness and enhancing flavor contrast. This technique enables chefs to achieve a unique balance of tender interior and crispy exterior, revolutionizing texture profiles in culinary applications.

Nitrogen-textured browning

Nitrogen sauteing uses liquid nitrogen to rapidly freeze and brown food surfaces, creating innovative textures with crisp edges and intense flavor concentration. This technique enhances Maillard reaction outcomes by enabling controlled temperature management, resulting in unique, nitrogen-textured browning not achievable through conventional sauteing.

Ultra-crisp nitro sauté

Ultra-crisp nitro saute leverages liquid nitrogen to rapidly freeze ingredients during the sauteing process, resulting in unparalleled texture contrast and exceptional crispness compared to traditional sauteing. This innovative technique enhances flavor retention and creates visually striking dishes by preserving moisture while delivering a uniquely crunchy exterior.

Vapor-shock sautéing

Vapor-shock sauteing leverages rapid steam infusion to create innovative textures by combining the high-heat, quick-cooking benefits of traditional sauteing with the moisture-retaining properties of nitrogen-assisted techniques. This method enhances surface caramelization while preserving interior juiciness, resulting in dishes with distinct vapor-induced crispiness and tender centers.

Thermo-contrast sauté technique

Thermo-contrast sauteing leverages rapid temperature changes to create innovative textures by combining intense heat with nitrogen cooling, resulting in crisp exteriors and tender interiors. This method enhances flavor development and visual appeal compared to traditional sauteing by introducing unique temperature gradients that alter food structure.

Molecular sauté foaming

Sauteing uses direct heat to cook and caramelize ingredients, developing rich Maillard flavors, while nitrogen sauteing leverages liquid nitrogen to rapidly chill and create unique textures through molecular foaming. Molecular saute foaming harnesses nitrogen's rapid phase change to trap air and create stable, airy foams that transform traditional sauteed dishes into innovative culinary experiences.

Sautéing vs Nitrogen Sautéing for innovative textures. Infographic

cookingdiff.com

cookingdiff.com