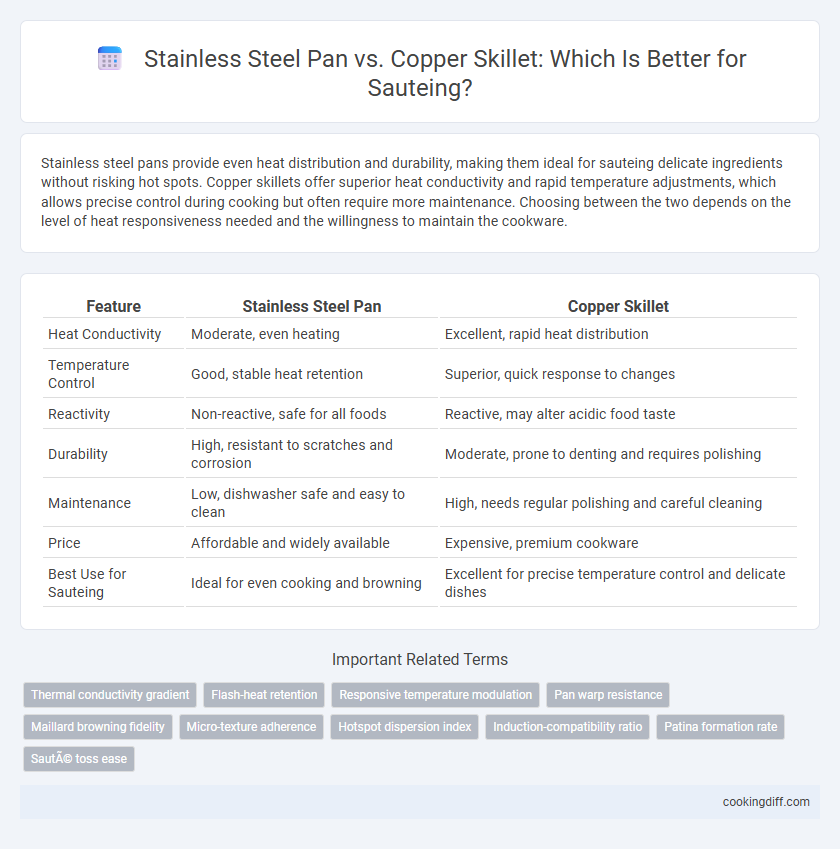

Stainless steel pans provide even heat distribution and durability, making them ideal for sauteing delicate ingredients without risking hot spots. Copper skillets offer superior heat conductivity and rapid temperature adjustments, which allows precise control during cooking but often require more maintenance. Choosing between the two depends on the level of heat responsiveness needed and the willingness to maintain the cookware.

Table of Comparison

| Feature | Stainless Steel Pan | Copper Skillet |

|---|---|---|

| Heat Conductivity | Moderate, even heating | Excellent, rapid heat distribution |

| Temperature Control | Good, stable heat retention | Superior, quick response to changes |

| Reactivity | Non-reactive, safe for all foods | Reactive, may alter acidic food taste |

| Durability | High, resistant to scratches and corrosion | Moderate, prone to denting and requires polishing |

| Maintenance | Low, dishwasher safe and easy to clean | High, needs regular polishing and careful cleaning |

| Price | Affordable and widely available | Expensive, premium cookware |

| Best Use for Sauteing | Ideal for even cooking and browning | Excellent for precise temperature control and delicate dishes |

Introduction to Sautéing: Stainless Steel vs. Copper

Sauteing requires precise temperature control to achieve even cooking and browning, making pan material a crucial factor. Stainless steel pans offer durability and excellent browning capabilities due to their high heat tolerance and non-reactive surface. Copper skillets provide superior thermal conductivity, allowing rapid temperature adjustments essential for delicate sauteing tasks.

Heat Conductivity: Stainless Steel Pan vs. Copper Skillet

Copper skillets offer superior heat conductivity compared to stainless steel pans, allowing for faster and more even heating during sauteing. Stainless steel pans heat more slowly and less evenly, which can result in hot spots and less precise temperature control.

- Copper's thermal conductivity - Copper conducts heat approximately 16 times better than stainless steel, enabling rapid temperature adjustments.

- Heat distribution - Copper skillets provide uniform heat across the cooking surface, reducing the risk of burning or uneven cooking.

- Durability and maintenance - Stainless steel pans are more resistant to corrosion and easier to maintain but sacrifice some thermal responsiveness.

The choice between stainless steel and copper skillets depends on the importance of precise heat control versus ease of use and maintenance for sauteing.

Responsiveness and Temperature Control

Stainless steel pans offer moderate responsiveness and retain heat evenly, making them suitable for steady sauteing but slower temperature adjustments. Copper skillets excel in responsiveness, allowing chefs to rapidly change heat levels with precision, ideal for delicate or quick-cooking tasks. Superior temperature control in copper enhances cooking accuracy, while stainless steel provides durability and even heat distribution.

Evenness of Cooking Surface

Stainless steel pans provide a durable cooking surface that heats evenly but may have slight hot spots compared to copper skillets. Copper skillets excel in heat conductivity, ensuring a more uniform cooking surface that responds quickly to temperature changes.

The evenness of a copper skillet allows for precise temperature control during sauteing, preventing food from burning or sticking. Stainless steel pans retain heat well but can develop uneven heat distribution without a high-quality base. Choosing between the two depends on the cook's preference for heat responsiveness versus durability and maintenance.

Durability and Longevity Comparison

| Material | Durability | Longevity |

|---|---|---|

| Stainless Steel Pan | Highly resistant to corrosion, scratches, and dents due to robust alloy composition. | Can last decades with proper care, making it a long-term investment for sauteing. |

| Copper Skillet | Prone to tarnishing and requires regular polishing, but copper core offers excellent heat conduction. | May have a shorter lifespan unless lined with durable stainless steel, especially with frequent use. |

Maintenance and Cleaning Requirements

Stainless steel pans require less intensive maintenance and can be easily cleaned with common dish soap and scrubbers, making them ideal for everyday use. Copper skillets demand more careful cleaning and occasional polishing to prevent tarnish and maintain their heat conduction efficiency.

- Stainless steel durability - Resists staining and corrosion, allowing simple dishwasher-safe cleaning.

- Copper skillet sensitivity - Prone to oxidation and requires regular polishing with specialized cleaners.

- Cleaning effort - Stainless steel pans are low-maintenance, while copper requires dedicated upkeep for optimal performance.

Weight and Handling in Sautéing

Which is easier to handle during sauteing, a stainless steel pan or a copper skillet? Stainless steel pans are generally heavier, providing stability but requiring more effort to maneuver. Copper skillets, being lighter, offer superior control and quicker response to wrist movements, enhancing precision in sauteing tasks.

Cost Considerations: Investment Value

Stainless steel pans offer a more affordable initial investment compared to copper skillets, which tend to be significantly more expensive due to their superior heat conductivity. While copper skillets require higher upfront costs, their durability and excellent heat distribution can justify the long-term value for serious home cooks or professionals.

- Stainless steel affordability - Stainless steel pans generally cost less, making them accessible for everyday cooking without compromising basic performance.

- Copper skillet expense - Copper skillets often carry a premium price tag reflecting advanced heat control and aesthetic appeal.

- Investment value - High-quality copper skillets can last decades, potentially offsetting their higher price through enhanced cooking precision and longevity.

Flavor Influence on Ingredients

Stainless steel pans offer even heating and excellent browning, which enhances the Maillard reaction and intensifies the natural flavors of sauteed ingredients. Their non-reactive surface prevents metallic taste transfer, preserving the purity of delicate spices and herbs.

Copper skillets provide superior heat conductivity, allowing precise temperature control that can prevent overcooking and maintain ingredient integrity. However, copper's reactive nature may impart a slight metallic taste when cooking acidic foods, subtly altering the flavor profile.

Related Important Terms

Thermal conductivity gradient

Copper skillets provide superior thermal conductivity with a gradient of approximately 401 W/m*K, enabling faster and more even heat distribution during sauteing, whereas stainless steel pans have a much lower conductivity around 16 W/m*K, resulting in slower heat response and less uniform cooking. This significant difference in thermal conductivity gradients allows copper skillets to maintain precise temperature control and reduce hotspots compared to stainless steel pans.

Flash-heat retention

Copper skillets offer superior flash-heat retention due to their high thermal conductivity, allowing precise temperature control and rapid heat recovery during sauteing. Stainless steel pans provide less efficient heat retention but excel in even cooking and durability, making them better for dishes requiring steady heat rather than quick temperature changes.

Responsive temperature modulation

Copper skillets offer superior responsive temperature modulation compared to stainless steel pans due to copper's excellent thermal conductivity, enabling precise heat control and quick adjustments during sauteing. Stainless steel pans heat more slowly and retain heat longer, which can cause less immediate temperature responsiveness and increased risk of overheating delicate ingredients.

Pan warp resistance

Stainless steel pans offer superior warp resistance during high-heat sauteing due to their durable construction and ability to maintain shape under thermal stress. Copper skillets, while excellent for heat conductivity, are more prone to warping unless reinforced with a stainless steel or nickel lining.

Maillard browning fidelity

Stainless steel pans provide consistent high heat retention crucial for achieving precise Maillard browning during sauteing, minimizing hot spots that can lead to uneven caramelization. Copper skillets offer superior heat conductivity, enabling rapid temperature adjustments that help maintain optimal surface temperature for peak Maillard reaction fidelity.

Micro-texture adherence

Stainless steel pans offer a slightly rougher micro-texture surface that enhances oil adhesion and promotes even browning during sauteing, preventing food from slipping. Copper skillets, with their smoother micro-texture, provide rapid heat conductivity but may require more precise temperature control to avoid sticking and ensure consistent food searing.

Hotspot dispersion index

Stainless steel pans typically have a higher hotspot dispersion index, leading to uneven heat distribution during sauteing, whereas copper skillets excel with superior thermal conductivity and minimal hotspots, ensuring consistent heat across the surface. This difference makes copper skillets preferable for precise temperature control and even cooking of delicate ingredients.

Induction-compatibility ratio

Stainless steel pans typically have a high induction-compatibility ratio due to their magnetic properties, making them highly efficient for sauteing on induction cooktops. Copper skillets often require a stainless steel base to work with induction, resulting in a lower compatibility ratio compared to pure stainless steel pans.

Patina formation rate

Copper skillets develop a patina much faster than stainless steel pans due to copper's higher reactivity with heat and food acids, which enhances flavor over time and provides a natural non-stick surface. Stainless steel pans form patina slowly, offering a more inert cooking surface that requires seasoning for similar benefits but maintains durability against corrosion.

Stainless steel pan vs copper skillet for sautéing. Infographic

cookingdiff.com

cookingdiff.com