Stainless steel pans offer excellent heat retention and even cooking, making them ideal for achieving a perfect saute with a desirable sear on meats and vegetables. Titanium pans are lighter and more durable, resisting scratches and corrosion but may not distribute heat as evenly, which can affect the consistency of sauteed dishes. Choosing between the two depends on whether you prioritize heat performance and cooking precision or lightweight durability and ease of maintenance.

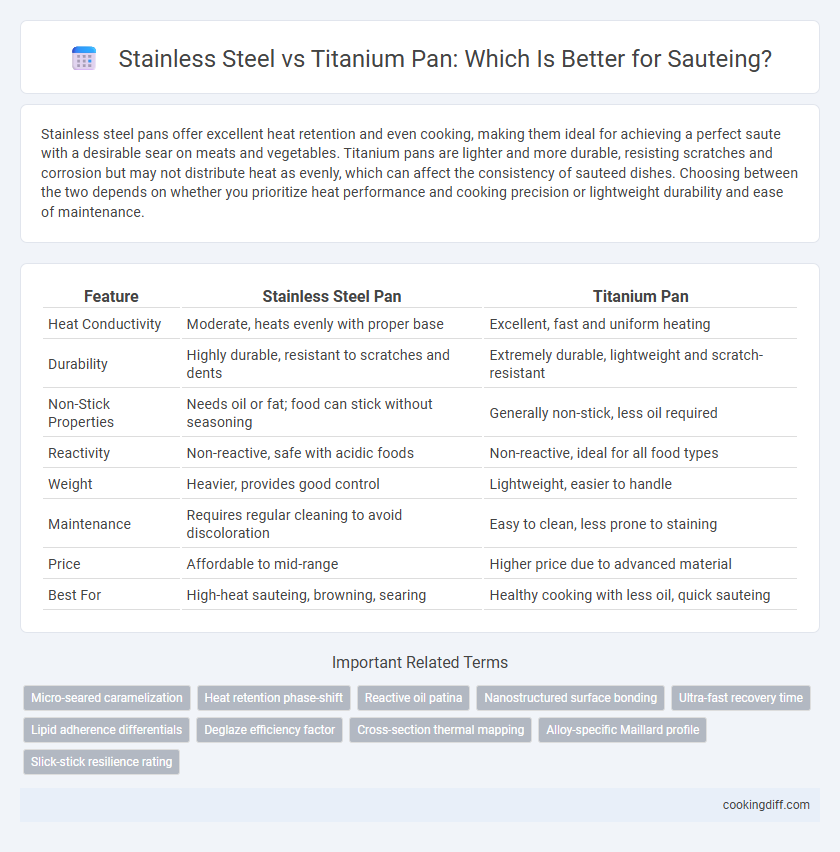

Table of Comparison

| Feature | Stainless Steel Pan | Titanium Pan |

|---|---|---|

| Heat Conductivity | Moderate, heats evenly with proper base | Excellent, fast and uniform heating |

| Durability | Highly durable, resistant to scratches and dents | Extremely durable, lightweight and scratch-resistant |

| Non-Stick Properties | Needs oil or fat; food can stick without seasoning | Generally non-stick, less oil required |

| Reactivity | Non-reactive, safe with acidic foods | Non-reactive, ideal for all food types |

| Weight | Heavier, provides good control | Lightweight, easier to handle |

| Maintenance | Requires regular cleaning to avoid discoloration | Easy to clean, less prone to staining |

| Price | Affordable to mid-range | Higher price due to advanced material |

| Best For | High-heat sauteing, browning, searing | Healthy cooking with less oil, quick sauteing |

Introduction: Stainless Steel vs Titanium Pans for Sautéing

Stainless steel pans offer excellent heat retention and even cooking, making them ideal for achieving a perfect saute. Titanium pans, known for their lightweight durability and non-reactive surface, provide quick heat responsiveness and ease of handling. Choosing between stainless steel and titanium depends on cooking style and preference for heat distribution versus weight.

Heat Conductivity: Stainless Steel vs Titanium Pans

Which pan offers better heat conductivity for sauteing, stainless steel or titanium? Stainless steel pans provide excellent heat distribution, ensuring even cooking without hot spots. Titanium pans heat quickly but tend to have uneven heat conduction, which can affect consistent sauteing results.

Durability and Longevity Comparison

Stainless steel pans offer exceptional durability due to their resistance to scratches, corrosion, and high heat, making them ideal for long-term use in sauteing. Titanium pans, while also durable and resistant to corrosion, tend to be lighter but may develop surface wear faster under intense cooking conditions.

The longevity of stainless steel pans is enhanced by their ability to withstand rigorous cleaning and frequent use without compromising performance. Titanium pans excel in weight and non-reactivity but may require more careful maintenance to preserve their sauteing surface over time.

Weight and Handling Differences

Stainless steel pans are generally heavier, providing stability and even heat distribution during sauteing, while titanium pans are lighter, enhancing ease of handling and maneuverability. The weight difference significantly impacts cooking comfort and prolonged use, especially when tossing ingredients.

- Stainless steel pan weight - Typically ranges from 3 to 5 pounds, contributing to a sturdy cooking experience.

- Titanium pan weight - Usually under 2 pounds, offering superior portability and less fatigue.

- Handling characteristics - Stainless steel pans require more effort to lift and tilt, whereas titanium pans allow quicker and more precise movements in the kitchen.

Nonstick Properties for Sautéing

Stainless steel pans lack inherent nonstick properties, requiring adequate oil and high heat to prevent food from sticking during sauteing. Titanium pans often feature a nonstick coating or naturally resist sticking, allowing for easier food release and less oil usage.

Nonstick titanium pans are preferable for sauteing delicate foods like fish and vegetables, as they reduce the risk of tearing. Stainless steel pans provide superior browning and fond development but demand skilful temperature control to avoid sticking. Choosing between the two depends on the balance between desired cooking technique and ease of cleanup.

Maintenance and Cleaning Requirements

Stainless steel pans require thorough cleaning to remove food residues and often benefit from polishing to maintain their appearance, but they are highly durable and resistant to stains. Titanium pans offer superior non-stick properties, making them easier to clean with minimal scrubbing and less risk of food sticking. Maintenance for titanium pans is generally lower, as they resist corrosion and discoloration more effectively than stainless steel under regular sauteing conditions.

Reactivity with Food Ingredients

Stainless steel pans exhibit low reactivity with acidic and alkaline food ingredients, making them ideal for sauteing tomatoes, wine-based sauces, and citrus-infused dishes without altering flavors. Their non-reactive surface preserves the integrity of delicate ingredients and prevents metallic taste contamination during cooking.

Titanium pans are highly non-reactive and resist corrosion when sauteing with acidic components, ensuring no leaching of metals into the food. This makes titanium cookware a safe choice for preparing dishes with vinegar, lemon juice, or wine while maintaining pure ingredient flavors.

Price and Value for Home Cooks

Stainless steel pans generally offer a more affordable option for home cooks seeking durability and versatility in sauteing. Titanium pans, while more expensive, provide excellent non-stick properties and lightweight handling that can justify the higher price for frequent sauteing.

- Cost Efficiency - Stainless steel pans typically cost less, making them accessible for most home kitchens without compromising on heat distribution.

- Durability and Maintenance - Titanium pans resist scratching and corrosion better, reducing replacement frequency despite the initial higher investment.

- Performance Value - The non-stick nature of titanium pans allows for healthier cooking with less oil, enhancing value for health-conscious home cooks.

Performance for Sautéing Vegetables and Meats

| Pan Material | Performance for Sauteing Vegetables | Performance for Sauteing Meats |

|---|---|---|

| Stainless Steel | Provides excellent heat retention and even cooking, ideal for achieving caramelization without sticking when preheated properly. | Allows for superior browning and searing due to high heat tolerance and consistent surface temperature, enhancing flavor development. |

| Titanium | Offers quick heat responsiveness and lightweight handling, but may have less even heat distribution which can affect consistent sauteing results. | Suitable for lighter searing tasks but may not achieve the same deep brown crust as stainless steel due to lower heat retention. |

Related Important Terms

Micro-seared caramelization

Stainless steel pans excel at achieving micro-seared caramelization during sauteing due to their superior heat retention and even temperature distribution, which promotes Maillard reactions for enhanced flavor development. Titanium pans, while lightweight and corrosion-resistant, often lack the optimal thermal conductivity needed for consistent searing, resulting in less pronounced caramelization.

Heat retention phase-shift

Stainless steel pans offer excellent heat retention due to their dense, multi-layer construction, allowing for consistent temperature control during sauteing. Titanium pans heat up quickly but cool rapidly, resulting in less stable heat retention and uneven cooking compared to stainless steel.

Reactive oil patina

Stainless steel pans develop a reactive oil patina that enhances non-stick properties and improves flavor over time, making them ideal for sauteing with high heat and oil. Titanium pans, while durable and lightweight, lack this natural oil patina formation, resulting in less seasoning and potentially less flavorful sauteed dishes.

Nanostructured surface bonding

Nanostructured surface bonding enhances heat retention and distribution in both stainless steel and titanium pans, improving sauteing performance by creating a more even cooking surface. Stainless steel pans with nanostructured coatings offer superior durability and resistance to corrosion, while titanium pans provide lightweight strength and quick responsiveness to temperature changes.

Ultra-fast recovery time

Stainless steel pans offer ultra-fast heat recovery, allowing for precise temperature control and consistent browning during sauteing. Titanium pans provide excellent durability but typically exhibit slower heat recovery, making stainless steel the preferred choice for rapid and even cooking.

Lipid adherence differentials

Stainless steel pans exhibit higher lipid adherence due to their micro-porous surface, which can result in uneven cooking and increased oil usage during sauteing. Titanium pans provide a smoother surface with lower lipid retention, promoting faster release of food and more efficient sauteing with less oil.

Deglaze efficiency factor

Stainless steel pans excel in deglaze efficiency due to their ability to develop flavorful fond, which dissolves easily when liquid is added, enhancing sauce depth. Titanium pans, while durable and lightweight, lack the same fond formation, resulting in less effective deglazing and reduced flavor complexity.

Cross-section thermal mapping

Stainless steel pans exhibit uneven heat distribution with hot spots during sauteing, as revealed by cross-section thermal mapping, which can lead to inconsistent cooking results. Titanium pans demonstrate superior thermal conductivity and more uniform heat distribution across the cooking surface, enhancing precise temperature control and even browning.

Alloy-specific Maillard profile

Stainless steel pans promote a robust Maillard reaction due to their superior heat retention and even distribution, enhancing caramelization and flavor complexity during sauteing. Titanium pans, with their rapid heat conduction and non-reactive surface, tend to produce a milder Maillard profile, resulting in subtler browning and less intense flavor development.

Stainless steel pan vs titanium pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com