Aluminum pots heat quickly and distribute warmth evenly, making them suitable for gentle simmering without hot spots. Copper core pots offer superior temperature control and responsiveness, allowing precise adjustments to maintain a steady simmer for delicate pet recipes. Both materials provide excellent heat conduction, but copper cores excel in consistent, low-heat cooking crucial for simmering pet food.

Table of Comparison

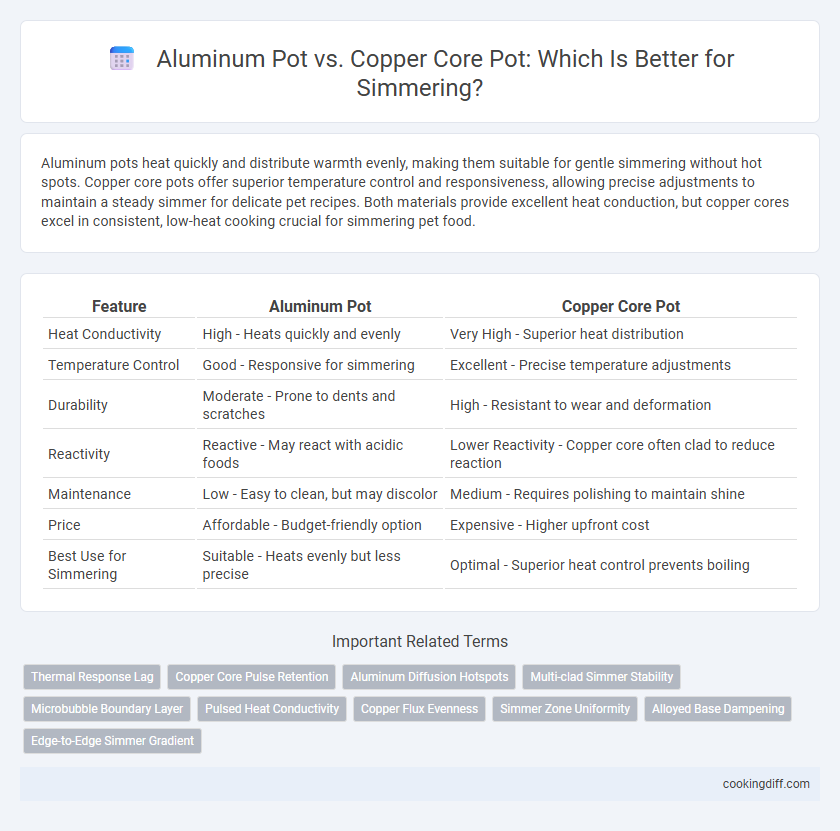

| Feature | Aluminum Pot | Copper Core Pot |

|---|---|---|

| Heat Conductivity | High - Heats quickly and evenly | Very High - Superior heat distribution |

| Temperature Control | Good - Responsive for simmering | Excellent - Precise temperature adjustments |

| Durability | Moderate - Prone to dents and scratches | High - Resistant to wear and deformation |

| Reactivity | Reactive - May react with acidic foods | Lower Reactivity - Copper core often clad to reduce reaction |

| Maintenance | Low - Easy to clean, but may discolor | Medium - Requires polishing to maintain shine |

| Price | Affordable - Budget-friendly option | Expensive - Higher upfront cost |

| Best Use for Simmering | Suitable - Heats evenly but less precise | Optimal - Superior heat control prevents boiling |

Introduction: Importance of Pot Material in Simmering

Choosing the right pot material is crucial for achieving precise temperature control during simmering. Aluminum pots and copper core pots each offer distinct thermal properties that impact cooking performance.

- Aluminum pots - Provide excellent heat conductivity and fast response to temperature changes, making them energy-efficient.

- Copper core pots - Offer superior heat distribution and consistent simmering temperatures due to copper's high thermal conductivity.

- Material influence - The choice between aluminum and copper core affects heat retention, temperature stability, and overall cooking results during simmering.

Aluminum Pots: Key Features and Benefits

Aluminum pots offer excellent heat conductivity, allowing for quick and even simmering without hot spots that can scorch food. Their lightweight nature makes them easy to handle during long cooking sessions, enhancing user comfort and control.

These pots are also highly affordable and resistant to corrosion, making them a practical and durable choice for everyday simmering tasks. The non-reactive surface of anodized aluminum ensures that flavors remain pure and untainted throughout the cooking process.

Copper Core Pots: Key Features and Benefits

| Copper Core Pots | Exceptional heat conductivity ensures precise temperature control essential for gentle simmering, preventing scorching or uneven cooking. |

| Thermal Responsiveness | Rapid heat adjustments allow cooks to maintain consistent simmering temperatures effortlessly, ideal for delicate sauces and soups. |

| Durability and Maintenance | High-quality copper core pots often feature stainless steel cladding that resists corrosion and simplifies cleaning, combining durability with culinary performance. |

Heat Distribution: Aluminum vs Copper Core

Aluminum pots offer excellent heat conduction, ensuring quick and even heat distribution for simmering. Copper core pots provide superior thermal responsiveness, allowing precise control of simmering temperatures.

Copper core pots maintain consistent heat across the surface, reducing hot spots that can cause food to stick or burn during simmering. Aluminum distributes heat evenly but tends to react more slowly to temperature changes compared to copper. The choice between aluminum and copper core depends on the desired balance between fast heat response and affordability.

Temperature Control and Simmering Precision

Aluminum pots offer excellent heat conductivity, allowing quick temperature adjustments for efficient simmering. Copper core pots provide superior temperature control and even heat distribution, minimizing hot spots and preventing food from scorching during delicate simmering tasks. For precise simmering, copper core cookware ensures consistent low heat, essential for recipes requiring gradual cooking.

Durability and Lifespan Comparison

Aluminum pots offer lightweight durability but tend to warp or degrade faster under continuous high heat compared to copper core pots. Copper core pots provide superior longevity due to their robust construction and resistance to corrosion when used properly.

- Aluminum Pot Durability - Aluminum is softer and more prone to dents and warping from uneven heating, reducing its effective lifespan under frequent simmering.

- Copper Core Longevity - Copper cores reinforce the pot structure, enhancing heat distribution and significantly extending the cookware's usable life.

- Maintenance Impact - Proper maintenance prolongs both types, but copper core pots generally withstand regular cleaning and wear better over time, preserving performance.

Reactivity with Ingredients: Which Is Safer?

Which pot material offers safer reactivity with ingredients during simmering? Aluminum pots may react with acidic foods, potentially altering taste and leaching metals, while copper core pots typically have a non-reactive stainless steel lining that prevents direct contact with food. This lining makes copper core pots safer for simmering a wide range of ingredients without chemical interaction concerns.

Maintenance and Cleaning Requirements

Aluminum pots require gentle cleaning to avoid surface damage, while copper core pots need regular polishing to maintain their appearance and heat conductivity. Both materials resist corrosion differently, impacting their maintenance routines.

- Aluminum pots are prone to discoloration - They should be washed with mild detergents and avoided from abrasive scrubbing.

- Copper core pots develop a patina - Polishing is necessary to prevent tarnish and preserve thermal efficiency.

- Both pots require hand washing - Dishwashers can degrade aluminum surfaces and copper finishes.

Proper care extends the lifespan and performance of each pot during simmering tasks.

Cost Considerations: Aluminum vs Copper Core Pots

Aluminum pots are generally more affordable than copper core pots, making them a cost-effective option for simmering tasks. Copper core pots, while more expensive, offer superior heat conductivity and precise temperature control, which can enhance cooking results. The initial investment in copper core pots often pays off through improved simmering performance and durability over time.

Related Important Terms

Thermal Response Lag

Aluminum pots offer fast thermal response with minimal lag, allowing precise temperature adjustments for simmering, while copper core pots provide superior heat conductivity but may exhibit slight thermal response lag due to their layered construction. Choosing between aluminum and copper core pots depends on balancing rapid heat changes against even heat distribution during simmering.

Copper Core Pulse Retention

Copper core pots excel in pulse retention during simmering due to copper's superior thermal conductivity, allowing precise temperature control and even heat distribution. Aluminum pots, while lightweight and affordable, often provide less consistent heat retention, making them less effective for delicate simmering tasks requiring steady warmth.

Aluminum Diffusion Hotspots

Aluminum pots often create diffusion hotspots due to uneven heat distribution, leading to inconsistent simmering and potential scorching of food. Copper core pots provide superior thermal conductivity, ensuring even heat diffusion and stable simmering temperatures for precise cooking control.

Multi-clad Simmer Stability

Multi-clad pots with a copper core offer superior simmer stability due to copper's excellent thermal conductivity, allowing for precise temperature control and consistent low heat ideal for delicate simmering. Aluminum pots, while lightweight and cost-effective, often provide less uniform heat distribution, which can make maintaining a steady simmer more challenging compared to multi-clad copper core cookware.

Microbubble Boundary Layer

Copper core pots provide superior heat conductivity, creating a stable microbubble boundary layer that maintains consistent simmering temperatures, essential for delicate cooking processes. Aluminum pots heat unevenly and can disrupt this microbubble boundary layer, resulting in fluctuating simmer temperatures and less precise cooking control.

Pulsed Heat Conductivity

Copper core pots exhibit superior pulsed heat conductivity compared to aluminum pots, enabling rapid and precise temperature adjustments essential for maintaining a consistent simmer. This enhanced thermal responsiveness minimizes hotspots and prevents scorching, making copper core cookware ideal for delicate simmering tasks.

Copper Flux Evenness

Copper core pots provide superior heat conductivity and exceptional heat distribution, ensuring consistent simmering temperatures and preventing hot spots. Aluminum pots heat quickly but often lack the copper flux evenness, resulting in uneven simmering and potential burning.

Simmer Zone Uniformity

Copper core pots offer superior simmer zone uniformity due to copper's excellent thermal conductivity, providing even heat distribution that minimizes hot spots during simmering. Aluminum pots heat quickly but often struggle with consistent temperature control, resulting in less uniform simmer zones compared to copper core cookware.

Alloyed Base Dampening

Aluminum pots with alloyed bases provide excellent heat distribution but may suffer from uneven heat retention, causing occasional temperature fluctuations during simmering. Copper core pots excel in alloyed base dampening, delivering superior thermal conductivity and steady temperature control essential for maintaining consistent simmering.

Aluminum pot vs Copper core pot for simmering. Infographic

cookingdiff.com

cookingdiff.com