Aluminum pots heat up quickly and offer excellent temperature control for simmering, making them ideal for delicate sauces and soups. Enameled cast iron retains heat longer and provides even heat distribution, which is perfect for slow, steady simmering over extended periods. Choosing between the two depends on whether rapid heat adjustment or consistent, long-term heat retention is more important for your cooking needs.

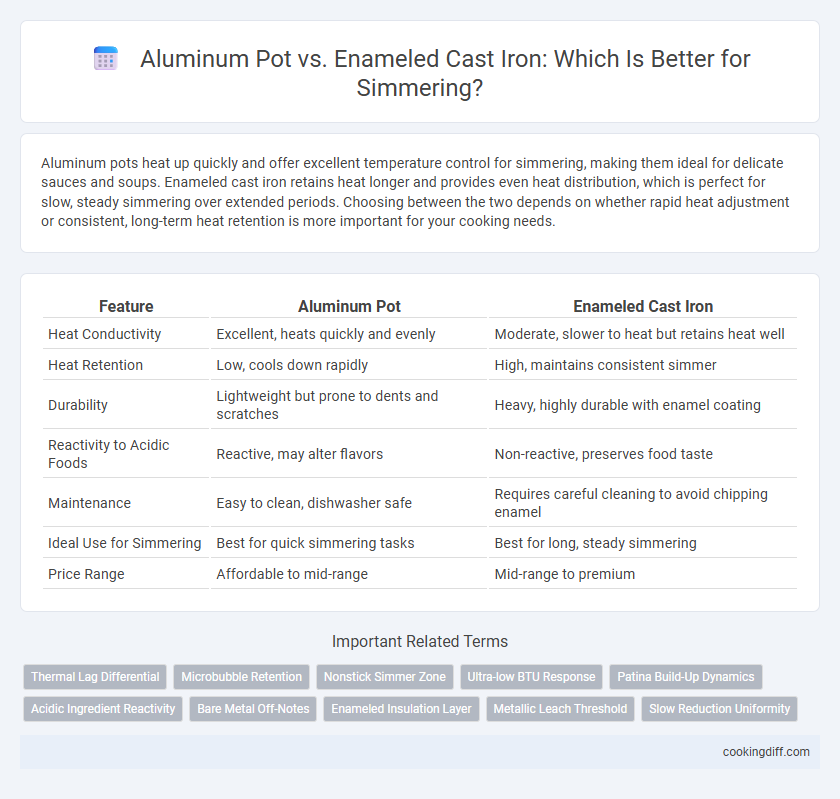

Table of Comparison

| Feature | Aluminum Pot | Enameled Cast Iron |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Moderate, slower to heat but retains heat well |

| Heat Retention | Low, cools down rapidly | High, maintains consistent simmer |

| Durability | Lightweight but prone to dents and scratches | Heavy, highly durable with enamel coating |

| Reactivity to Acidic Foods | Reactive, may alter flavors | Non-reactive, preserves food taste |

| Maintenance | Easy to clean, dishwasher safe | Requires careful cleaning to avoid chipping enamel |

| Ideal Use for Simmering | Best for quick simmering tasks | Best for long, steady simmering |

| Price Range | Affordable to mid-range | Mid-range to premium |

Introduction: Choosing the Right Pot for Simmering

Aluminum pots offer excellent thermal conductivity, allowing for quick and even heating ideal for precise simmering control. Enameled cast iron provides superior heat retention and a non-reactive surface, making it perfect for slow, consistent simmering without altering the flavor of acidic ingredients. Selecting the right pot depends on the desired heat distribution and cooking duration for optimal simmering results.

Aluminum Pot vs Enameled Cast Iron: Material Overview

What are the key differences between aluminum pots and enameled cast iron for simmering? Aluminum pots offer excellent heat conductivity and lightweight handling, allowing precise temperature control during simmering. Enameled cast iron provides superior heat retention and even distribution, making it ideal for slow, consistent simmering but tends to be heavier and requires more careful maintenance.

Heat Distribution and Retention in Simmering

| Material | Heat Distribution | Heat Retention |

|---|---|---|

| Aluminum Pot | Excellent heat distribution due to high thermal conductivity, ensuring even simmering without hot spots. | Lower heat retention, requiring more frequent temperature adjustments during simmering for consistent results. |

| Enameled Cast Iron | Moderate heat distribution with slower response time, but provides steady and consistent simmering temperatures. | Superior heat retention, maintaining stable simmer conditions for extended periods with minimal heat fluctuations. |

Reactivity and Flavor Impact on Simmered Dishes

Aluminum pots react with acidic ingredients during simmering, which can alter the flavor of dishes by imparting a metallic taste. Enameled cast iron, with its non-reactive surface, preserves the intended flavors and prevents discoloration of acidic or delicate foods.

The non-reactive enamel coating ensures even heat distribution without chemical interaction, maintaining the balance of flavors throughout the simmering process. Aluminum cookware may leach metals into food, potentially affecting both taste and nutritional quality when simmering for extended periods.

Durability and Longevity of Aluminum vs Enameled Cast Iron

Aluminum pots offer excellent heat conduction but may dent or warp over time, affecting their durability. They typically have a shorter lifespan compared to heavier cookware materials, requiring replacement every few years with frequent use.

Enameled cast iron pots provide superior longevity, resisting rust and maintaining structural integrity for decades under proper care. The durable enamel coating protects the cast iron base, making it highly resistant to chipping and corrosion during simmering.

Ease of Cleaning and Maintenance for Simmering Pans

Aluminum pots offer lightweight construction that makes cleaning quick and effortless, especially after simmering acidic foods. Enameled cast iron pans require careful maintenance to avoid chipping the enamel, but they resist staining and retain flavors well during long simmering sessions.

- Aluminum pots clean easily - Their smooth surfaces allow food residues to wash away with minimal scrubbing.

- Enameled cast iron resists stains - The glass coating prevents food from penetrating, preserving pan appearance.

- Maintenance differs significantly - Aluminum needs gentle detergents to avoid discoloration, whereas enameled cast iron demands careful handling to protect the enamel finish.

Choosing between these depends on your preference for lightweight cleaning versus durable, stain-resistant cookware.

Weight and Handling: Ergonomics in Simmering

Aluminum pots are significantly lighter than enameled cast iron, enhancing ease of handling during prolonged simmering. The ergonomic benefits of lightweight aluminum reduce strain on wrists, making it ideal for frequent stirring or transferring.

- Weight Difference - Aluminum pots typically weigh less than half of enameled cast iron counterparts, providing superior maneuverability.

- Heat Distribution - While aluminum offers rapid heat conduction, its lightweight nature requires careful handling to maintain stability.

- Ergonomic Design - Enameled cast iron often features robust handles but its heavy weight can cause fatigue, impacting long simmering sessions.

Compatibility with Cooktops and Ovens

Aluminum pots are highly compatible with most cooktops, including gas, electric, and induction, due to their excellent heat conductivity. Enameled cast iron performs exceptionally well in ovens and on stovetops but may be less effective on induction without a magnetic base.

- Aluminum Pot Compatibility - Aluminum conducts heat efficiently and works on gas, electric, and induction cooktops.

- Enameled Cast Iron Cooktop Use - Enameled cast iron is durable and ideal for all stovetops but requires a magnetic base for induction compatibility.

- Oven Performance - Both aluminum pots and enameled cast iron are oven safe, though enameled cast iron withstands higher temperatures without damage.

Cost Analysis: Budgeting for the Best Simmering Pot

Aluminum pots offer a cost-effective option for simmering due to their low price and efficient heat conduction, making them ideal for budget-conscious cooks. Enameled cast iron pots, while significantly more expensive upfront, provide superior heat retention and durability, which can justify the higher initial investment over time. Evaluating long-term use and maintenance costs is essential when budgeting for the best simmering pot, as enameled cast iron often outlasts aluminum alternatives despite the steeper cost.

Related Important Terms

Thermal Lag Differential

Aluminum pots offer rapid heat conduction with minimal thermal lag, ensuring precise temperature control during simmering, whereas enameled cast iron retains heat longer, causing slower temperature adjustments and higher thermal lag. This differential affects simmering efficiency, with aluminum providing quick responsiveness and enameled cast iron delivering steady, sustained heat ideal for low and slow cooking.

Microbubble Retention

Enameled cast iron excels in microbubble retention during simmering due to its thick, porous surface that traps heat evenly, promoting consistent low heat and minimal bubble disruption. Aluminum pots heat rapidly but lack the thermal mass to maintain stable microbubble formation, which can lead to uneven simmering and fluctuating temperatures.

Nonstick Simmer Zone

Aluminum pots offer a superior nonstick simmer zone due to their excellent thermal conductivity, ensuring even heat distribution and preventing food from sticking during low-temperature cooking. Enameled cast iron provides durability and heat retention but may develop hotspots, making it less effective for maintaining a consistent nonstick simmering surface.

Ultra-low BTU Response

Aluminum pots offer ultra-low BTU response, rapidly adjusting to minimal heat for precise simmering control, whereas enameled cast iron retains heat longer but reacts slower to low flame changes. This makes aluminum ideal for delicate simmering processes requiring quick temperature regulation and energy efficiency.

Patina Build-Up Dynamics

Aluminum pots feature rapid heat conduction but lack the patina build-up characteristic of enameled cast iron, which enhances flavor development during prolonged simmering. Enameled cast iron promotes gradual seasoning and patina formation on its surface, improving heat retention and creating nuanced taste profiles over time.

Acidic Ingredient Reactivity

Aluminum pots react with acidic ingredients such as tomatoes or vinegar, causing metallic flavors and potential discoloration, while enameled cast iron provides a non-reactive surface that preserves the taste and color of acidic dishes during simmering. The durable enamel coating also prevents nutrient loss and unwanted chemical reactions, making enameled cast iron superior for slow cooking acidic recipes.

Bare Metal Off-Notes

Aluminum pots can cause bare metal off-notes during simmering due to their reactive surface, which may leach metallic flavors into acidic or prolonged-cooked dishes. Enameled cast iron, with its non-reactive coating, effectively prevents off-flavors, maintaining the integrity of delicate simmered recipes without imparting metallic taste.

Enameled Insulation Layer

Enameled cast iron pots feature a durable, non-reactive enamel insulation layer that provides even heat distribution and excellent heat retention, making them ideal for consistent simmering without hot spots. This enamel coating also prevents metal interaction with acidic ingredients, preserving flavor and ensuring easier cleaning compared to aluminum pots.

Metallic Leach Threshold

Aluminum pots tend to release small amounts of aluminum ions into food when simmering acidic ingredients, potentially exceeding safe metallic leach thresholds, while enameled cast iron provides a non-reactive cooking surface that prevents metal leaching. Choosing enameled cast iron reduces the risk of ingesting trace metals, making it a safer option for prolonged simmering of acidic dishes.

Aluminum Pot vs Enameled Cast Iron for simmering. Infographic

cookingdiff.com

cookingdiff.com