Enamel pots offer excellent heat distribution and non-reactive surfaces, making them ideal for simmering delicate dishes without altering flavors. Stoneware pots retain heat evenly and provide a natural, porous texture that enhances slow cooking but may require more careful temperature control to prevent cracking. Both materials are durable, but enamel pots tend to be easier to clean and maintain for consistent simmering results.

Table of Comparison

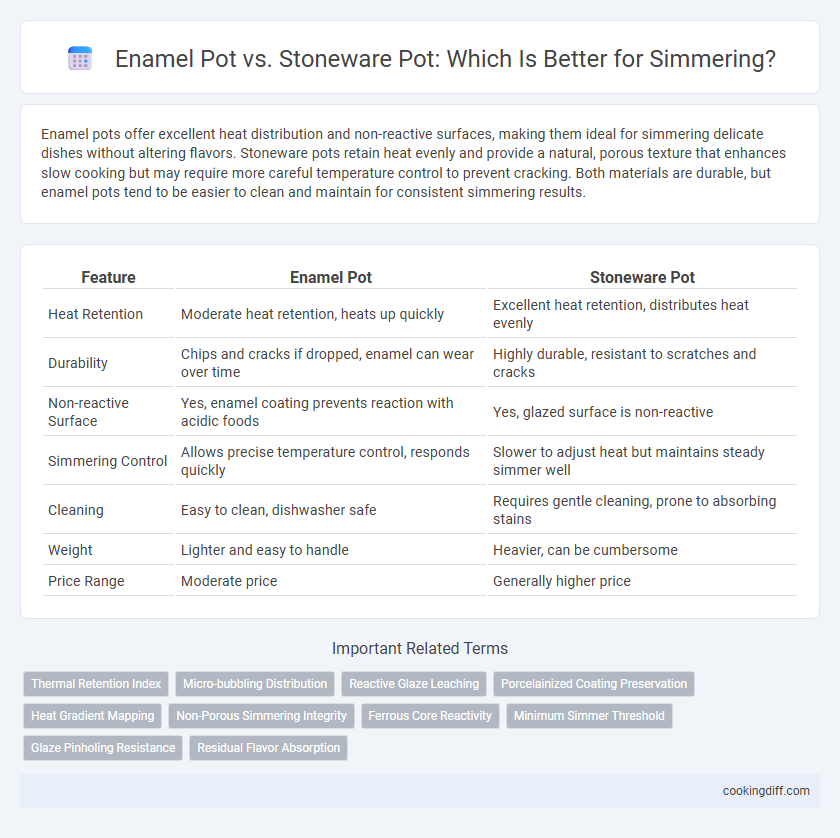

| Feature | Enamel Pot | Stoneware Pot |

|---|---|---|

| Heat Retention | Moderate heat retention, heats up quickly | Excellent heat retention, distributes heat evenly |

| Durability | Chips and cracks if dropped, enamel can wear over time | Highly durable, resistant to scratches and cracks |

| Non-reactive Surface | Yes, enamel coating prevents reaction with acidic foods | Yes, glazed surface is non-reactive |

| Simmering Control | Allows precise temperature control, responds quickly | Slower to adjust heat but maintains steady simmer well |

| Cleaning | Easy to clean, dishwasher safe | Requires gentle cleaning, prone to absorbing stains |

| Weight | Lighter and easy to handle | Heavier, can be cumbersome |

| Price Range | Moderate price | Generally higher price |

Introduction to Simmering: Why Pot Material Matters

Simmering requires consistent, gentle heat to slowly cook ingredients and develop flavors without boiling. Enamel pots offer smooth, non-reactive surfaces that prevent sticking and are ideal for maintaining steady temperatures during simmering.

Stoneware pots retain heat evenly, promoting uniform cooking but can take longer to adjust temperature, which may affect delicate simmering processes. Choosing the right pot material influences heat distribution and flavor outcomes in simmered dishes.

Enamel Pots vs Stoneware Pots: Key Material Differences

Enamel pots feature a smooth, non-porous surface coated with glass fused to metal, offering excellent heat conductivity and resistance to staining, ideal for precise simmering. Stoneware pots, made from dense, natural clay, provide superior heat retention and even distribution, creating a stable environment for slow cooking and simmering. The choice between enamel and stoneware depends on cooking style, with enamel pots favored for quick temperature adjustments and stoneware for maintaining consistent low heat over time.

Heat Distribution: Enamel Pots Compared to Stoneware

Enamel pots offer superior heat distribution due to their metal cores, ensuring even simmering without hot spots. Stoneware pots retain heat longer but heat up more slowly and can have uneven temperature zones.

- Enamel pots feature a metal base - This base conducts heat quickly and spreads it evenly across the surface.

- Stoneware pots offer excellent heat retention - They maintain simmering temperatures steadily for extended periods once heated.

- Heat distribution differences affect cooking control - Enamel pots allow more precise simmering adjustments compared to stoneware's slower response.

Retaining Steady Simmer: Which Pot Performs Better?

Enamel pots provide excellent heat retention and distribute heat evenly, making them ideal for maintaining a steady simmer over long periods. Stoneware pots, while capable of retaining heat, tend to heat up slower and may require more frequent adjustments to keep a consistent simmer. For optimal temperature control during simmering, enamel pots generally perform better due to their superior heat conductivity and stability.

Flavor Preservation: Impact of Pot Type on Taste

Enamel pots provide a non-reactive surface that preserves the natural flavors of ingredients during simmering, preventing metallic tastes. Stoneware pots offer excellent heat retention, enhancing the melding of flavors but may absorb some odors over time.

- Enamel pots are non-porous - this prevents flavor absorption, maintaining the purity of the dish.

- Stoneware's porous nature - allows subtle flavor absorption that can enrich future meals but may alter delicate tastes.

- Heat distribution differs - enamel heats quickly and evenly, while stoneware retains heat longer, affecting simmering consistency and flavor development.

Durability and Longevity: Enamel vs Stoneware Pots

Enamel pots feature a durable glass coating over metal, providing resistance to scratches and chipping, making them suitable for long-term simmering use. Stoneware pots, made from natural clay fired at high temperatures, offer robust structural integrity but can be prone to cracking under rapid temperature changes.

Enamel pots maintain longevity through their non-porous surface, which prevents stain absorption and simplifies cleaning after extended simmering. Stoneware's porous nature may absorb flavors and moisture over time, potentially affecting durability and flavor retention during prolonged cooking.

Ease of Cleaning: Maintenance for Simmering Pots

| Enamel Pot | Non-porous surface prevents food from sticking, making it easy to clean after simmering. Durable enamel coating resists stains and odors, requiring minimal maintenance. Suitable for dishwasher cleaning, saving time and effort. |

| Stoneware Pot | Porous material may absorb flavors or stains, needing more thorough cleaning after simmering. Requires careful hand washing to avoid cracking or damaging the glaze. Periodic seasoning may be necessary to maintain its integrity and ease of cleaning. |

Safety Concerns: Toxicity and Reactivity in Cooking

Enamel pots are coated with a glass-like layer that prevents direct contact between the metal base and food, reducing the risk of leaching harmful chemicals during simmering. Stoneware pots are made from natural clay and fired at high temperatures, typically posing minimal reactivity or toxicity concerns in cooking.

- Enamel coating safety - High-quality enamel prevents metal exposure and is generally non-toxic, but chipped enamel can expose reactive metals underneath.

- Stoneware inertness - Properly glazed stoneware is inert and non-reactive, ensuring no chemical transfer to simmered foods.

- Heat resistance - Both enamel and stoneware tolerate low and slow simmering temperatures safely without releasing toxins.

Using intact enamel or glazed stoneware pots ensures safe simmering without toxic or reactive risks commonly associated with bare metals or porous materials.

Versatility for Other Cooking Methods

Enamel pots offer excellent versatility beyond simmering, excelling in baking, roasting, and searing due to their heat retention and durable coating. Stoneware pots are ideal for slow cooking and baking, providing even heat distribution but limited stovetop versatility compared to enamel.

Enamel pots are compatible with various heat sources including induction, gas, and electric, making them suitable for multiple cooking techniques such as frying and braising. Stoneware pots perform best in the oven, with their porous material enhancing moisture retention for stews and casseroles. Their limited stovetop use restricts versatility primarily to oven-based recipes.

Related Important Terms

Thermal Retention Index

Enamel pots typically feature a Thermal Retention Index of approximately 0.7, indicating moderate heat hold suitable for gentle simmering, while stoneware pots exhibit a higher index near 0.9, providing superior thermal retention for consistent low-temperature cooking. The enhanced heat preservation of stoneware ensures more even simmering, minimizing temperature fluctuations and improving flavor development over extended cooking periods.

Micro-bubbling Distribution

Enamel pots provide even heat retention and consistent micro-bubbling distribution, which helps maintain a gentle simmer without hot spots, preserving the delicate flavors of slow-cooked dishes. Stoneware pots excel in gradual heat absorption but often have uneven micro-bubbling, requiring careful temperature control to prevent boiling or uneven cooking.

Reactive Glaze Leaching

Enamel pots with non-reactive, vitreous coatings prevent reactive glaze leaching, making them ideal for simmering acidic ingredients without altering flavor or safety. Stoneware pots may pose a risk of reactive glaze leaching due to their porous surfaces and less stable glazes, potentially affecting the food's taste and introducing unwanted chemicals during prolonged simmering.

Porcelainized Coating Preservation

Enamel pots feature a durable porcelainized coating that prevents food from sticking and resists acidic ingredients during simmering, preserving both flavor and pot integrity over time. Stoneware pots, while excellent for even heat distribution, lack this protective enamel layer, making them more susceptible to staining and retaining odors during prolonged simmering.

Heat Gradient Mapping

Enamel pots offer superior heat gradient mapping with their smooth, non-porous surfaces that distribute heat evenly, ensuring consistent simmering temperatures and preventing hotspots. Stoneware pots tend to have uneven heat distribution due to their porous material, which may result in fluctuating simmering temperatures and less precise heat control.

Non-Porous Simmering Integrity

Enamel pots, with their non-porous glass coating, prevent food absorption and maintain simmering integrity by providing even heat distribution without flavor contamination. Stoneware pots, although durable, are more porous and prone to moisture absorption, which can compromise simmering consistency and flavor purity over time.

Ferrous Core Reactivity

Enamel pots, often featuring a ferrous core, provide superior reactivity and heat distribution for simmering, ensuring consistent low-temperature cooking without hot spots. Stoneware pots lack a ferrous core, resulting in slower heat conduction and less precise temperature control during prolonged simmering.

Minimum Simmer Threshold

Enamel pots offer a lower minimum simmer threshold, allowing precise temperature control for gentle simmering without scorching, whereas stoneware pots retain heat longer but require higher temperatures to maintain a consistent simmer. This makes enamel pots ideal for delicate sauces and slow-cooked recipes that need steady low heat.

Glaze Pinholing Resistance

Enamel pots offer superior glaze pinholing resistance during simmering due to their smooth, non-porous surface that prevents gas bubbles from forming and creating imperfections. Stoneware pots, while sturdy, are more prone to glaze pinholing because their porous clay body can release gases under heat, compromising the glaze integrity.

Enamel pot vs Stoneware pot for simmering. Infographic

cookingdiff.com

cookingdiff.com