Simmering extracts flavors through prolonged heat exposure, allowing ingredients to release their essential oils and compounds slowly, resulting in a rich, robust taste. Vacuum infusion accelerates this process by using reduced pressure to draw flavors into liquids more quickly, preserving delicate aromas that simmering might diminish. While simmering enhances depth and complexity, vacuum infusion offers a faster, more precise method for flavor extraction, ideal for achieving nuanced profiles in less time.

Table of Comparison

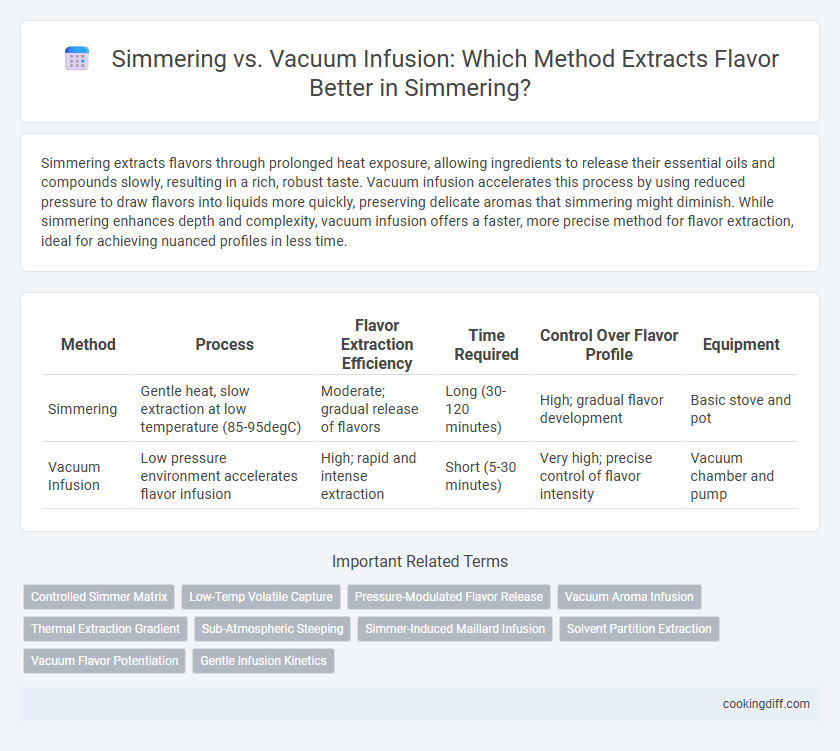

| Method | Process | Flavor Extraction Efficiency | Time Required | Control Over Flavor Profile | Equipment |

|---|---|---|---|---|---|

| Simmering | Gentle heat, slow extraction at low temperature (85-95degC) | Moderate; gradual release of flavors | Long (30-120 minutes) | High; gradual flavor development | Basic stove and pot |

| Vacuum Infusion | Low pressure environment accelerates flavor infusion | High; rapid and intense extraction | Short (5-30 minutes) | Very high; precise control of flavor intensity | Vacuum chamber and pump |

Introduction to Flavor Extraction Methods

Flavor extraction methods significantly impact the intensity and purity of culinary infusions. Simmering and vacuum infusion are two prevalent techniques that utilize heat and pressure variations to extract flavors efficiently.

- Simmering - involves heating ingredients in liquid at a low temperature to gently release and blend flavors over time.

- Vacuum Infusion - employs reduced pressure to force liquids into porous ingredients, accelerating flavor absorption without heat damage.

- Efficiency and Flavor Profile - simmering often yields a richer, more complex flavor, while vacuum infusion provides quicker extraction with preserved freshness.

What is Simmering?

Simmering is a gentle cooking technique where food is cooked in liquid at temperatures just below boiling, typically between 185degF and 205degF (85degC to 96degC). This method allows gradual flavor extraction, breaking down ingredients to release aromatic compounds without harsh boiling that can cause bitterness or loss of delicate flavors.

This slow heat process preserves the subtle taste nuances of herbs, spices, and other ingredients, making it ideal for soups, stocks, and sauces. Unlike vacuum infusion, simmering relies on consistent, moderate heat and liquid agitation to gently draw out flavors over time.

Understanding Vacuum Infusion

Vacuum infusion enhances flavor extraction by using reduced pressure to draw flavors rapidly into ingredients, unlike simmering which relies on heat over time. This method preserves volatile compounds that often dissipate during long simmering processes.

Understanding vacuum infusion involves recognizing its ability to infuse flavors deeply and evenly without prolonged exposure to heat. It accelerates the marination process, extracting complex flavors efficiently while maintaining ingredient texture. This technique offers precision in culinary applications where delicate flavors and aromas are essential.

Science Behind Simmering for Flavor

Simmering leverages gentle heat to break down food fibers and release water-soluble flavor compounds effectively without reaching boiling, which can degrade delicate aromas. This controlled temperature range, typically between 85degC to 95degC, optimizes the extraction of flavors by facilitating chemical reactions such as Maillard browning and lipid breakdown.

The gradual heat exposure in simmering allows for the thorough diffusion of volatile oils and amino acids into the cooking liquid, enhancing flavor depth and complexity. Unlike vacuum infusion, simmering relies on prolonged heat transfer, creating a dynamic environment for flavor molecules to interact and intensify naturally.

How Vacuum Infusion Enhances Taste

Vacuum infusion accelerates flavor extraction by removing air and allowing liquids to penetrate ingredients more deeply and uniformly than simmering. This method preserves delicate flavors that simmering can degrade through prolonged heat exposure.

- Enhanced penetration - Vacuum infusion forces liquids into porous food structures for richer taste absorption.

- Temperature control - It operates at lower temperatures, maintaining vibrant and fresh flavors.

- Reduced oxidation - The vacuum environment limits oxygen contact, preventing flavor loss and preserving aroma.

Vacuum infusion delivers a more intense and pure flavor profile compared to traditional simmering techniques.

Temperature and Time: Key Differences

Simmering uses moderate heat around 85-95degC to extract flavors slowly over an extended period, typically 30 minutes to several hours. Vacuum infusion operates at lower temperatures, often below 40degC, reducing infusion time to minutes while preserving delicate flavors.

- Simmering involves higher temperatures - Heat accelerates chemical reactions, intensifying flavor extraction but risks degrading heat-sensitive compounds.

- Vacuum infusion uses reduced pressure - Lower boiling points under vacuum allow flavors to infuse faster at mild temperatures.

- Time required varies significantly - Simmering requires hours, whereas vacuum infusion usually completes within minutes.

Ingredients Best Suited for Each Technique

Simmering is ideal for robust ingredients like tough cuts of meat, root vegetables, and whole spices, allowing flavors to meld slowly over time. Vacuum infusion excels with delicate herbs, fruits, and quick-release aromatics by rapidly infusing flavors without heat degradation. Choosing the right technique depends on ingredient texture and desired intensity, maximizing flavor extraction efficiently.

Equipment Needed: Simmering vs Vacuum Infusion

| Method | Equipment Needed |

|---|---|

| Simmering | Basic stovetop or heat source, pot or saucepan, and a lid; minimal specialized equipment required for slow cooking and flavor extraction. |

| Vacuum Infusion | Vacuum chamber, vacuum pump, sealable bags or containers, and precise temperature control tools; demands specialized apparatus for efficient and rapid flavor infusion under reduced pressure. |

Pros and Cons of Each Method

Which method extracts flavor more efficiently, simmering or vacuum infusion? Simmering allows for slow, consistent heat that enhances deep flavor development but can overcook delicate ingredients. Vacuum infusion speeds up flavor absorption by removing air with low pressure, preserving freshness though it may lack the complexity that heat extraction provides.

Related Important Terms

Controlled Simmer Matrix

Controlled Simmer Matrix enhances flavor extraction by maintaining precise temperature and consistent heat distribution, fostering optimal release of volatile compounds and aromatic profiles. Unlike vacuum infusion, which relies on pressure differentials, simmering enables gradual, uniform infusion of flavors, preserving delicate nuances and achieving a balanced taste profile.

Low-Temp Volatile Capture

Simmering extracts flavors by heating ingredients just below boiling, which risks losing delicate volatile compounds due to prolonged heat exposure, whereas vacuum infusion operates at low temperatures and reduced pressure, effectively capturing and preserving these fragile aromatics. This low-temp volatile capture in vacuum infusion enhances flavor intensity and complexity without degrading heat-sensitive notes.

Pressure-Modulated Flavor Release

Pressure-modulated flavor release in vacuum infusion enables more efficient extraction of volatile compounds compared to traditional simmering, preserving delicate aromas and intensifying taste profiles. Simmering relies on steady heat application, which can degrade sensitive flavor molecules, whereas vacuum infusion uses reduced pressure to enhance solvent penetration and accelerate flavor absorption without thermal damage.

Vacuum Aroma Infusion

Vacuum Aroma Infusion enhances flavor extraction by using low pressure to open food pores, allowing deeper penetration of aromatic compounds compared to traditional simmering methods. This technique preserves volatile flavors and intensifies taste without the heat degradation typically caused by prolonged simmering.

Thermal Extraction Gradient

Simmering utilizes a consistent thermal extraction gradient by maintaining temperatures just below boiling, allowing gentle flavor release without degrading volatile compounds. Vacuum infusion accelerates extraction by reducing pressure, lowering boiling points, and enabling flavor compounds to infuse more thoroughly at lower temperatures.

Sub-Atmospheric Steeping

Sub-atmospheric steeping under vacuum infusion efficiently extracts flavors by reducing pressure, which accelerates the diffusion of aromatic compounds from ingredients compared to traditional simmering methods. This technique preserves the delicate nuances in ingredients, enhancing flavor intensity while minimizing thermal degradation seen in prolonged simmering.

Simmer-Induced Maillard Infusion

Simmering enhances flavor extraction through Simmer-Induced Maillard Infusion, where moderate heat promotes the Maillard reaction, developing complex, savory notes by browning amino acids and reducing sugars. Unlike vacuum infusion, simmering intensifies flavor depth naturally without pressure, creating robust taste profiles ideal for slow-cooked dishes.

Solvent Partition Extraction

Vacuum infusion enhances solvent partition extraction by rapidly driving flavors into the solvent under reduced pressure, resulting in higher concentration and purity of extracted compounds compared to traditional simmering. Simmering relies on heat to diffuse flavors but often leads to thermal degradation and lower extraction efficiency, making vacuum infusion a superior method for capturing delicate flavor profiles.

Vacuum Flavor Potentiation

Vacuum infusion enhances flavor extraction by lowering the boiling point of liquids, allowing aromatic compounds to permeate ingredients more efficiently than traditional simmering methods. This technique preserves delicate flavors and intensifies taste profiles through accelerated infusion under reduced pressure.

Simmering vs Vacuum Infusion for flavor extraction. Infographic

cookingdiff.com

cookingdiff.com