A copper pot offers superior heat conductivity and precise temperature control, making it ideal for delicate simmering tasks that require consistent, even heat. Stockpots, typically made from stainless steel, provide larger capacity and durability but may have less responsive heat distribution compared to copper. Choosing between them depends on the simmering needs, with copper pots excelling in precision and stockpots in volume and sturdiness.

Table of Comparison

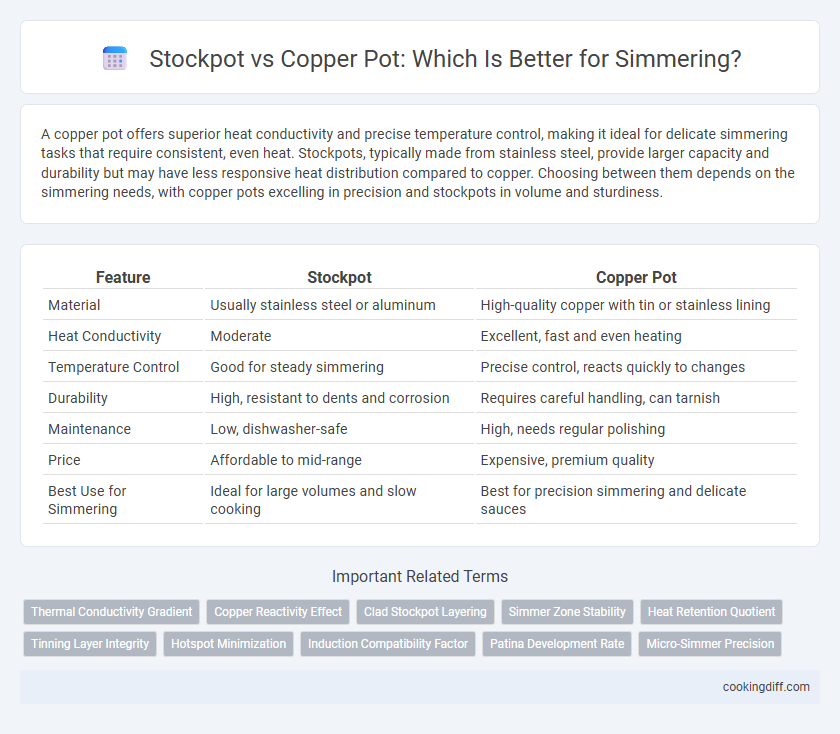

| Feature | Stockpot | Copper Pot |

|---|---|---|

| Material | Usually stainless steel or aluminum | High-quality copper with tin or stainless lining |

| Heat Conductivity | Moderate | Excellent, fast and even heating |

| Temperature Control | Good for steady simmering | Precise control, reacts quickly to changes |

| Durability | High, resistant to dents and corrosion | Requires careful handling, can tarnish |

| Maintenance | Low, dishwasher-safe | High, needs regular polishing |

| Price | Affordable to mid-range | Expensive, premium quality |

| Best Use for Simmering | Ideal for large volumes and slow cooking | Best for precision simmering and delicate sauces |

Introduction: Stockpot vs Copper Pot for Simmering

Simmering requires precise temperature control to maintain a gentle, consistent heat without boiling. Both stockpots and copper pots offer unique advantages depending on heat conductivity and material composition.

- Stockpots - Typically made from stainless steel or aluminum, stockpots provide even heating and ample capacity for large batches.

- Copper pots - Copper's superior thermal conductivity allows for rapid temperature adjustments, ideal for delicate simmering tasks.

- Heat control - Copper pots excel at maintaining steady, low temperatures, while stockpots offer durability and ease of use for extended simmering.

Material Differences: Stockpot and Copper Pot

Which material between a stockpot and a copper pot is better for simmering? Stockpots, typically made from stainless steel or aluminum, provide even heat distribution and excellent heat retention, making them ideal for slow simmering. Copper pots respond quickly to temperature changes, allowing precise control during simmering but require careful maintenance to prevent tarnishing and reactive reactions with acidic foods.

Heat Conductivity and Temperature Control

Copper pots offer superior heat conductivity, allowing for rapid and even heat distribution during simmering. This precise temperature control minimizes hot spots and reduces the risk of food burning or sticking.

Stockpots, typically made from stainless steel or aluminum, have slower heat conduction, which can lead to uneven simmering temperatures. Their thickness retains heat well but offers less fine-tuned temperature adjustments compared to copper cookware.

Simmering Performance: Stockpot vs Copper Pot

Stockpots, typically made from stainless steel or aluminum, offer even heat distribution but may take longer to reach and maintain a gentle simmer compared to copper pots. Copper pots excel in temperature control due to their superior thermal conductivity, allowing precise adjustment to sustain delicate simmering without scorching.

While stockpots are ideal for large-volume simmering tasks due to their capacity and durability, copper pots provide unmatched responsiveness, essential for recipes requiring strict temperature management. Choosing between them depends on balancing simmering performance with size needs and budget considerations.

Durability and Maintenance Comparisons

Stockpots are typically made from stainless steel, offering high durability and resistance to rust and stains, making them low-maintenance for simmering tasks. Copper pots provide superior heat conductivity but require regular polishing to prevent tarnish and can be prone to dents if not handled carefully. Stainless steel stockpots maintain their appearance and performance over time with minimal upkeep, whereas copper pots demand more frequent maintenance to preserve their aesthetic and functional qualities.

Flavor Development: Does Pot Material Matter?

| Flavor Development | Stockpots, typically made from stainless steel or aluminum, provide even heat distribution crucial for consistent simmering, which helps in gradual flavor extraction and melding in soups and stews. Copper pots excel in precise temperature control due to their superior thermal conductivity, allowing for delicate simmering that enhances subtle flavor nuances without burning. The choice between stockpot and copper pot significantly affects simmering outcomes, as copper's quick response to heat changes promotes more delicate flavor development compared to the steadier heat retention of stockpots. |

Size and Versatility for Simmering

A stockpot offers larger capacity ideal for simmering large batches of soups and stews, while a copper pot provides precise temperature control perfect for delicate simmering tasks. The versatility of a stockpot is centered on volume, whereas copper pots excel in temperature responsiveness and even heat distribution.

- Stockpot Size Advantage - Typically ranges from 8 to 20 quarts, accommodating bulk cooking needs effectively.

- Copper Pot Temperature Control - Copper's superior conductivity allows fine-tuned simmering without hot spots.

- Simmering Versatility - Stockpots handle large meals, whereas copper pots are suited for sauces and gentle heat applications.

Cost Considerations: Investment vs Everyday Use

Stockpots offer a budget-friendly option for simmering with durable materials suited for everyday use, while copper pots require a higher initial investment due to their premium quality and superior heat conductivity. The choice depends on balancing upfront cost with long-term cooking performance and maintenance expenses.

- Affordability - Stockpots are generally much cheaper than copper pots, making them accessible for most kitchens.

- Durability - Stockpots withstand daily wear and tear without extensive upkeep, ideal for frequent simmering tasks.

- Initial Investment - Copper pots require a significant upfront expenditure but offer precise temperature control for delicate simmering.

Evaluating cost considerations against cooking frequency and precision needs determines the best pot for simmering.

Pros and Cons: Stockpot vs Copper Pot

Stockpots offer excellent heat retention and large capacity, making them ideal for long, slow simmering of soups and stews, but they can be heavy and slow to respond to temperature changes. Copper pots provide superior heat conductivity and precise temperature control, allowing for quick adjustments during simmering, though they require more maintenance and are typically more expensive. Choosing between stockpots and copper pots depends on the balance between durability, heat responsiveness, and ease of care needed for your simmering tasks.

Related Important Terms

Thermal Conductivity Gradient

Copper pots exhibit superior thermal conductivity, allowing for rapid and even heat distribution essential for precise simmering, while stockpots, typically made from stainless steel or aluminum, have a lower thermal conductivity gradient, resulting in slower heat responsiveness and less uniform temperature control. This difference ensures copper pots maintain stable simmering temperatures more efficiently, reducing the risk of scorching or uneven cooking compared to stockpots.

Copper Reactivity Effect

Copper pots provide superior heat conductivity for precise temperature control during simmering, but their high reactivity with acidic ingredients can alter flavors and damage the pot's surface unless lined with a non-reactive metal. Stockpots, typically made from stainless steel or aluminum, avoid these reactivity issues, making them more versatile for simmering a variety of dishes without risk of metallic taste or discoloration.

Clad Stockpot Layering

Clad stockpots feature multiple layers of stainless steel and aluminum, ensuring even heat distribution and preventing hot spots during simmering, which is essential for maintaining a gentle, consistent temperature. Copper pots excel in thermal conductivity but often lack the durable layering that clad stockpots provide, making the latter a more reliable choice for precise simmering control.

Simmer Zone Stability

Copper pots offer superior simmer zone stability due to their excellent thermal conductivity, ensuring precise temperature control and even heat distribution essential for consistent simmering. Stockpots, typically made from stainless steel or aluminum, have less thermal responsiveness, making temperature regulation less accurate during prolonged simmering.

Heat Retention Quotient

Copper pots exhibit a superior heat retention quotient compared to stockpots, maintaining consistent simmering temperatures for longer durations due to copper's high thermal conductivity. Stockpots, often made from stainless steel or aluminum, typically lose heat faster, requiring more frequent temperature adjustments during simmering to preserve steady heat levels.

Tinning Layer Integrity

Stockpots with high-quality stainless steel and an even copper core ensure superior heat distribution and maintain tinning layer integrity for safer simmering, preventing contamination from exposed copper. Copper pots require regular re-tinning to preserve the protective layer, as frequent exposure to acidic simmered foods can degrade tinning and compromise food safety.

Hotspot Minimization

Copper pots offer superior heat conductivity, ensuring even heat distribution and minimizing hotspots during simmering, which prevents uneven cooking and scorching. In contrast, stockpots, typically made from stainless steel or aluminum, may develop hotspots due to less uniform heat diffusion, requiring careful heat regulation to maintain consistent simmering temperatures.

Induction Compatibility Factor

Stockpots with magnetic stainless steel or iron bottoms offer superior induction compatibility, ensuring even heat distribution for precise simmering control. Copper pots, while excellent for thermal conductivity, often require a stainless steel core or base to work efficiently on induction cooktops.

Patina Development Rate

Copper pots develop a patina more rapidly during simmering due to their high thermal conductivity and reactive surface, enhancing flavor complexity over time. Stockpots, typically made from stainless steel or aluminum, exhibit slower patina formation, providing more stable heat distribution but less influence on the simmered food's flavor profile.

Stockpot vs Copper pot for simmering. Infographic

cookingdiff.com

cookingdiff.com