Traditional low-heat baking for vegetable chips involves slow-cooking at a controlled temperature, preserving natural flavors and achieving a crispy texture without added oils. A food dehydrator uses consistent low heat and airflow to efficiently remove moisture, resulting in evenly dried, shelf-stable chips with enhanced crunchiness. Both methods emphasize nutrient retention, but dehydrators often provide greater energy efficiency and precise temperature control for optimal dehydration.

Table of Comparison

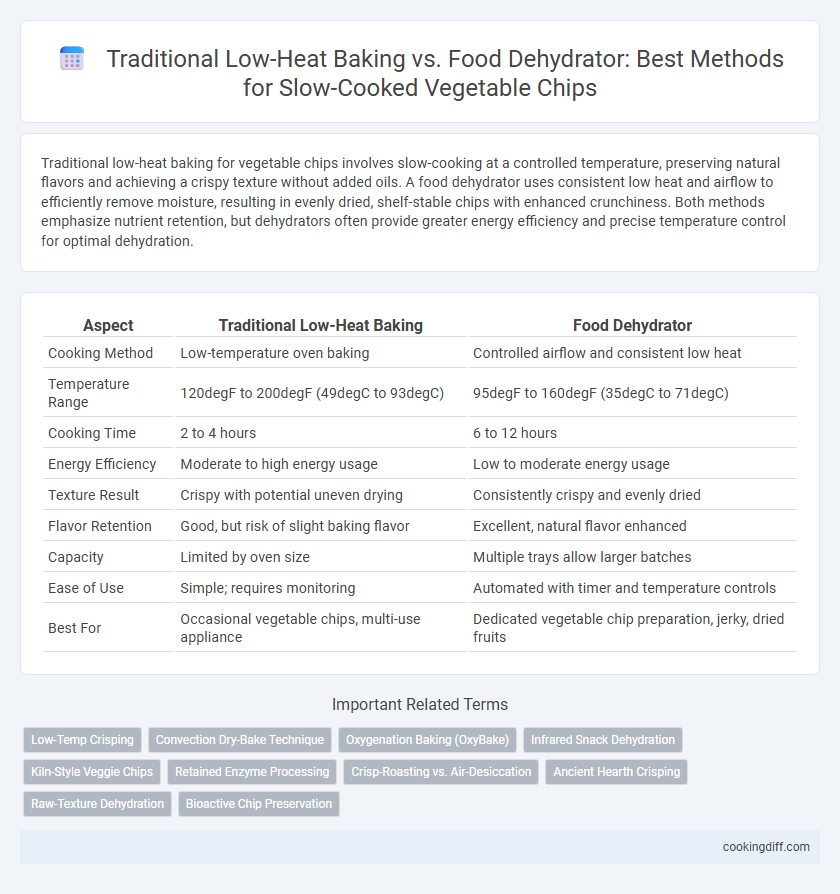

| Aspect | Traditional Low-Heat Baking | Food Dehydrator |

|---|---|---|

| Cooking Method | Low-temperature oven baking | Controlled airflow and consistent low heat |

| Temperature Range | 120degF to 200degF (49degC to 93degC) | 95degF to 160degF (35degC to 71degC) |

| Cooking Time | 2 to 4 hours | 6 to 12 hours |

| Energy Efficiency | Moderate to high energy usage | Low to moderate energy usage |

| Texture Result | Crispy with potential uneven drying | Consistently crispy and evenly dried |

| Flavor Retention | Good, but risk of slight baking flavor | Excellent, natural flavor enhanced |

| Capacity | Limited by oven size | Multiple trays allow larger batches |

| Ease of Use | Simple; requires monitoring | Automated with timer and temperature controls |

| Best For | Occasional vegetable chips, multi-use appliance | Dedicated vegetable chip preparation, jerky, dried fruits |

Understanding Low-Heat Baking: Traditional Methods for Vegetable Chips

Traditional low-heat baking for vegetable chips involves maintaining oven temperatures between 120degF and 150degF to slowly evaporate moisture while preserving nutrients and texture. This method relies on extended baking times, often several hours, to achieve crispy, evenly dried chips without burning.

Food dehydrators use consistent low temperatures and controlled airflow to efficiently remove moisture from vegetables, reducing drying time compared to conventional ovens. Unlike traditional baking, dehydrators minimize the risk of uneven drying and offer better energy efficiency. Both methods preserve the natural flavors and essential vitamins of vegetables but differ in precision and convenience.

What is a Food Dehydrator? Modern Approach to Making Vegetable Chips

A food dehydrator is an electric appliance designed to remove moisture from vegetables and fruits through controlled low heat and airflow, preserving nutrients while enhancing crispness. Unlike traditional low-heat baking, which uses an oven and requires more time and attention, dehydrators offer precise temperature settings and consistent drying conditions for uniform vegetable chips. This modern approach enables faster preparation with minimal energy consumption and better texture control, making it ideal for creating healthy, crunchy snacks.

Comparing Cooking Times: Low-Heat Baking vs Food Dehydrator

Traditional low-heat baking for vegetable chips typically requires 1.5 to 3 hours at temperatures between 150degF and 200degF, allowing gradual moisture removal while maintaining texture. Food dehydrators use consistent low heat ranging from 125degF to 160degF and operate for 6 to 12 hours, providing more controlled airflow for even drying. Comparing cooking times, low-heat baking is faster but may lead to less uniform dehydration compared to food dehydrators designed for optimal moisture extraction.

Nutrient Retention: Which Method Preserves More Vitamins?

Traditional low-heat baking and food dehydrators both use gentle heat to preserve nutrients in vegetable chips, but food dehydrators maintain a more consistent temperature, reducing nutrient degradation. Vitamin C and B-complex vitamins are better preserved in dehydrated vegetables due to minimal heat exposure and reduced oxidation compared to baking.

- Temperature Control - Food dehydrators operate at steady low temperatures, minimizing vitamin loss.

- Exposure to Air - Baking exposes vegetables to higher air circulation, leading to increased oxidation of sensitive nutrients.

- Processing Time - Dehydrators typically dehydrate over longer periods at lower temperatures, which helps maintain more vitamins.

Using a food dehydrator is generally more effective for preserving vitamins during vegetable chip preparation than traditional low-heat baking.

Texture and Flavor: Differences in Final Vegetable Chip Results

Traditional low-heat baking produces vegetable chips with a crisp exterior but often retains slight moisture, resulting in a tender bite. Food dehydrators remove moisture uniformly, creating evenly crunchy chips with intensified natural flavors.

- Texture Variation - Low-heat baking can lead to uneven crispiness due to inconsistent heat distribution.

- Flavor Concentration - Dehydrators preserve and enhance the vegetable's inherent sweetness and earthiness.

- Final Moisture Content - Dehydrated chips achieve lower residual moisture, extending shelf life and crunchiness.

Equipment and Setup: Oven vs Dehydrator Requirements

What are the key differences in equipment and setup between traditional low-heat baking and using a food dehydrator for vegetable chips? Traditional low-heat baking requires an oven capable of maintaining stable low temperatures, usually between 120degF and 200degF, along with baking sheets and proper airflow management. Food dehydrators are specialized devices designed with multiple trays and built-in fans to circulate air evenly, ensuring consistent dehydration without the need for manual temperature adjustments.

Energy Efficiency: Analyzing Power Consumption

| Method | Power Consumption (Watts) | Energy Efficiency |

|---|---|---|

| Traditional Low-Heat Baking | 500-600 | Higher energy use due to longer preheating and inconsistent heat distribution |

| Food Dehydrator | 250-500 | More efficient with steady low-temperature operation and reduced heat loss |

Batch Size and Convenience: Which is Best for Large Quantities?

Traditional low-heat baking accommodates larger batch sizes, making it ideal for preparing substantial quantities of vegetable chips in one go. Ovens allow for multiple trays to be baked simultaneously, increasing efficiency for bulk production.

Food dehydrators often have limited tray capacity but offer consistent temperature control and require less active monitoring. For large-scale batch preparation, ovens provide greater convenience and volume handling, while dehydrators excel in precision and energy efficiency for smaller batches.

Cost Comparison: Initial Investment and Maintenance

Traditional low-heat baking requires a standard oven, which often involves higher energy costs compared to energy-efficient food dehydrators designed specifically for drying vegetables. Food dehydrators typically have a lower initial investment and reduced maintenance expenses, making them cost-effective for regular vegetable chip preparation.

- Oven Cost - Conventional ovens can cost $400-$1,000 with higher electricity usage leading to increased operational costs.

- Dehydrator Cost - Food dehydrators range from $40 to $200 and use less energy, reducing ongoing utility bills.

- Maintenance - Ovens require occasional professional servicing, while dehydrators need minimal upkeep, mainly cleaning and occasional part replacement.

Related Important Terms

Low-Temp Crisping

Low-temp crisping in traditional low-heat baking uses gradual heat around 200degF to evenly remove moisture from vegetable chips, enhancing flavor and texture without burning. Food dehydrators offer precise temperature control and airflow around 125degF to 160degF, optimizing nutrient retention and consistent dehydration for perfectly crisp chips.

Convection Dry-Bake Technique

The convection dry-bake technique in traditional low-heat baking evenly circulates hot air around vegetables, preserving natural flavors and achieving crisp textures without added oils. Food dehydrators use similar low heat and airflow but often lack the consistent convection currents, making the convection oven method superior for producing lightweight, evenly dried vegetable chips with enhanced taste and reduced moisture content.

Oxygenation Baking (OxyBake)

Traditional low-heat baking for vegetable chips relies on consistent temperatures around 120-140degF to slowly remove moisture while maintaining texture, whereas Oxygenation Baking (OxyBake) enhances the process by circulating oxygen to accelerate dehydration and improve crispness without sacrificing nutrients. Food dehydrators typically use low heat and airflow but lack the oxygenation feature of OxyBake, resulting in longer drying times and potentially less vibrant flavor retention.

Infrared Snack Dehydration

Infrared snack dehydration in food dehydrators preserves nutrients and achieves a crisp texture by evenly distributing low heat without overcooking, unlike traditional low-heat baking which often results in uneven drying and nutrient loss. This method enhances the preservation of antioxidants and vitamins in vegetable chips while reducing the overall preparation time.

Kiln-Style Veggie Chips

Kiln-style veggie chips achieve a crispy texture through traditional low-heat baking at temperatures around 200degF to 225degF, preserving natural flavors and nutrients by slowly removing moisture. Food dehydrators operate at similar low temperatures but ensure even airflow and consistent drying, producing uniformly crisp chips with enhanced shelf life compared to conventional oven methods.

Retained Enzyme Processing

Traditional low-heat baking preserves a moderate amount of enzymes in vegetable chips by maintaining temperatures typically below 200degF, which slows nutrient degradation while enhancing flavor through Maillard reactions. In contrast, food dehydrators operate at lower, more controlled temperatures around 130degF to 160degF, optimizing retained enzyme activity by minimizing heat damage and preserving maximum nutritional value.

Crisp-Roasting vs. Air-Desiccation

Traditional low-heat baking for vegetable chips uses crisp-roasting techniques that gently caramelize sugars and enhance natural flavors by applying consistent dry heat, resulting in a crunchy texture with rich, roasted notes. Food dehydrators achieve crispness through air-desiccation, removing moisture via circulating warm air at lower temperatures, which preserves nutrients and color but often yields a drier, less caramelized chip.

Ancient Hearth Crisping

Ancient hearth crisping relies on traditional low-heat baking methods that slowly remove moisture from vegetables, enhancing natural flavors and preserving nutrients through gradual heat exposure. In contrast, food dehydrators use controlled temperature and airflow technology to achieve consistent dehydration, offering efficiency but often lacking the rustic texture and depth of taste associated with slow-cooked hearth crisped chips.

Raw-Texture Dehydration

Traditional low-heat baking for vegetable chips uses temperatures around 150degF to 200degF, which can soften the natural texture, while food dehydrators maintain precise, lower temperatures between 95degF and 135degF that preserve the raw-texture and nutrients during dehydration. This controlled environment in food dehydrators enhances crispiness and retains enzymes, vitamins, and minerals better than conventional slow-baking methods.

Traditional Low-Heat Baking vs Food Dehydrator for Vegetable Chips Infographic

cookingdiff.com

cookingdiff.com