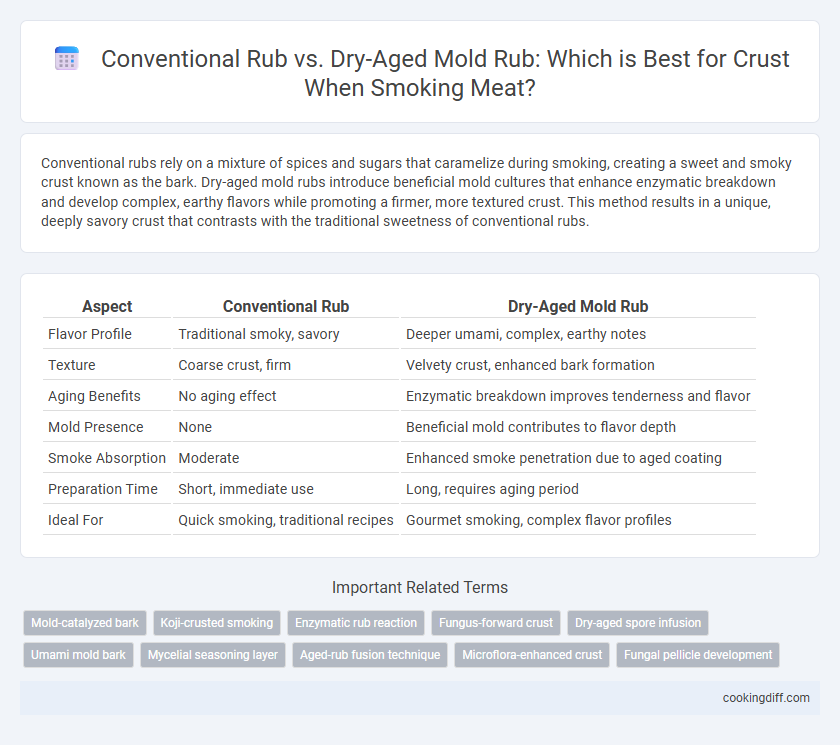

Conventional rubs rely on a mixture of spices and sugars that caramelize during smoking, creating a sweet and smoky crust known as the bark. Dry-aged mold rubs introduce beneficial mold cultures that enhance enzymatic breakdown and develop complex, earthy flavors while promoting a firmer, more textured crust. This method results in a unique, deeply savory crust that contrasts with the traditional sweetness of conventional rubs.

Table of Comparison

| Aspect | Conventional Rub | Dry-Aged Mold Rub |

|---|---|---|

| Flavor Profile | Traditional smoky, savory | Deeper umami, complex, earthy notes |

| Texture | Coarse crust, firm | Velvety crust, enhanced bark formation |

| Aging Benefits | No aging effect | Enzymatic breakdown improves tenderness and flavor |

| Mold Presence | None | Beneficial mold contributes to flavor depth |

| Smoke Absorption | Moderate | Enhanced smoke penetration due to aged coating |

| Preparation Time | Short, immediate use | Long, requires aging period |

| Ideal For | Quick smoking, traditional recipes | Gourmet smoking, complex flavor profiles |

Understanding Conventional Rubs in Smoking

Conventional rubs in smoking typically consist of a blend of salt, sugar, and spices applied directly to the meat's surface to enhance flavor and create a crust. These rubs penetrate the meat during the smoking process, contributing to the Maillard reaction, which develops the characteristic smoky bark.

Unlike dry-aged mold rubs, conventional rubs do not involve microbial activity but rely on seasoning and smoke interaction for taste and texture. Proper application and balanced seasoning are crucial for achieving a well-developed crust that locks in moisture and intensifies the smoked flavor profile.

Exploring Dry-Aged Mold Rubs for Smoking

Dry-aged mold rubs develop complex flavors through microbial activity, enhancing the crust's depth during smoking. Conventional rubs rely on immediate seasoning impact but lack the matured umami and texture that dry-aging imparts.

- Flavor Complexity - Dry-aged mold rubs introduce nuanced, earthy notes that evolve over time, enriching the smoked meat's sensory profile.

- Crust Texture - The enzymatic effects of mold create a firmer, more pronounced bark compared to the softer crust from conventional rubs.

- Microbial Influence - Beneficial molds foster maturation and preservation, unlike traditional rubs which act primarily as surface seasoning without microbial enhancement.

Flavor Profiles: Conventional Rub vs Dry-Aged Mold Rub

Conventional rubs typically offer a bold, spicy flavor profile with a balanced mix of salt, sugar, and common herbs and spices that enhance the meat's natural taste. Dry-aged mold rubs develop complex umami notes and subtle earthiness due to enzyme activity during aging, which intensifies the crust's depth and character. This unique flavor from dry-aged mold rubs creates a richer, more nuanced smoking experience compared to the straightforward seasoning of conventional rubs.

Texture and Crust Development

Conventional rubs create a uniform crust by forming a dry, seasoned layer that enhances texture through caramelization during smoking. This method promotes a consistent bark but may lack depth in flavor complexity.

Dry-aged mold rubs, however, introduce enzymatic activity that breaks down proteins and fats, resulting in a more tender texture and a richer, more complex crust development. The mold's biochemical processes intensify umami flavors, producing a unique and artisanal crust characteristic.

Ingredient Differences: Traditional vs Mold Rubs

Conventional rubs typically rely on a blend of salt, sugar, and traditional spices to enhance flavor and crust formation during smoking. Dry-aged mold rubs incorporate specific molds and enzymes that break down proteins, intensifying umami and creating a uniquely textured crust.

Traditional rub ingredients focus on immediate seasoning impact, using straightforward components like paprika, black pepper, and garlic powder to develop a flavorful bark. In contrast, mold rubs leverage the natural aging process, with mold cultures such as Penicillium nalgiovense contributing complex fermentation notes. These molds influence both biochemical reactions and moisture retention, yielding a richer, more savory crust that deepens the overall smoked meat profile.

Smoking Techniques: Impact on Rub Performance

Conventional rubs create a flavorful crust quickly by binding spices to meat surfaces through moisture. Dry-aged mold rubs enhance crust complexity by promoting enzymatic breakdown, resulting in deeper smoke absorption and tenderness.

- Conventional Rub Efficiency - Quickly forms a crust due to surface moisture aiding spice adherence during early smoking stages.

- Dry-Aged Mold Enzymatic Action - Enzymes break down proteins, allowing smoke compounds to penetrate more deeply for richer flavor.

- Smoke Absorption - Dry-aged rubs improve smoke retention in the crust, intensifying smoky flavor profile over longer cook times.

Visual Appeal: Color and Bark Formation

How do conventional rubs compare to dry-aged mold rubs in terms of visual appeal for smoked meats? Conventional rubs typically create a uniform, deep brown bark with a consistent texture, enhancing the traditional smoked appearance. Dry-aged mold rubs promote complex color variations and a thicker, more textured bark, resulting in a unique and visually striking crust.

Best Cuts of Meat for Each Rub

Choosing between conventional rubs and dry-aged mold rubs significantly impacts the crust texture and flavor complexity of smoked meats. Each rub type pairs best with specific cuts to maximize taste and tenderness.

- Conventional Rubs - Best suited for cuts like brisket and pork shoulder that benefit from bold, smoky seasoning to create a robust crust.

- Dry-Aged Mold Rubs - Ideal for premium cuts such as ribeye and strip loin, enhancing natural umami and adding a subtle, earthy crust complexity.

- Fat Content Consideration - Higher fat cuts absorb dry-aged mold rubs better, allowing the mold's enzymes to tenderize and enrich the crust effectively.

Selecting the appropriate rub tailored to the meat cut ensures optimal flavor development and crust formation in smoked dishes.

Health and Safety Considerations

| Conventional rubs often contain high levels of salt and preservatives that can contribute to heart disease and hypertension, posing health risks during smoking processes. |

| Dry-aged mold rubs involve natural fermentation and mold cultures that may reduce harmful additives but require strict hygiene to prevent mycotoxin contamination, ensuring food safety. |

| Choosing dry-aged mold rubs can improve flavor complexity while minimizing exposure to synthetic chemicals, but proper temperature and humidity control is essential to maintain safety standards. |

Related Important Terms

Mold-catalyzed bark

Mold-catalyzed bark develops a complex, umami-rich crust during dry-aging, resulting from enzymatic reactions that break down proteins and fats in the meat's surface. Conventional rubs often create a simple, smoky crust that lacks the depth and tenderness imparted by the mold-active dry-aged rub process.

Koji-crusted smoking

Koji-crusted smoking combines dry-aged mold rub to develop a uniquely flavorful crust, enhancing umami and tenderness compared to the traditional conventional rub. This method promotes enzymatic breakdown during smoking, resulting in a savory, deeply textured exterior that elevates the overall smoking experience.

Enzymatic rub reaction

Dry-aged mold rub enhances the enzymatic rub reaction by breaking down proteins and fats more effectively than conventional rubs, resulting in a richer, more complex crust. The enzymatic activity from the mold accelerates flavor development and tenderizes the meat surface, creating a distinctive, savory bark during smoking.

Fungus-forward crust

Dry-aged mold rubs create a fungus-forward crust richer in complex umami flavors and distinct earthy aromas compared to conventional rubs, which typically emphasize sweeter or spicier profiles. The microbial activity in mold-rubbed meats enhances enzyme breakdown, intensifying savory depth and fostering a unique textured bark prized in advanced smoking techniques.

Dry-aged spore infusion

Dry-aged mold rub introduces complex, savory umami flavors through spore infusion that penetrates the meat, enhancing crust depth beyond the surface seasoning of conventional rubs. This process promotes enzymatic breakdown during aging, resulting in a uniquely tender texture and rich aromatic crust that intensifies the smoking experience.

Umami mold bark

Conventional rubs create a flavorful crust by combining spices and sugar, but dry-aged mold rubs develop a unique umami mold bark rich in amino acids and microbial complexity that enhances depth and savoriness. This umami mold bark results from natural enzymatic reactions during dry aging, intensifying the smoky crust's taste profile with robust and earthy notes.

Mycelial seasoning layer

Dry-aged mold rub enhances the crust with a unique mycelial seasoning layer that fosters deeper umami flavors and improved texture compared to conventional rubs, promoting a richer smoke ring and more complex aroma. The natural enzymatic activity of the mycelium breaks down proteins and fats, intensifying savory notes while forming a robust, flavorful bark.

Aged-rub fusion technique

The aged-rub fusion technique enhances smoking by combining the deep flavor profile of dry-aged mold rub with the classic intensity of a conventional rub, creating a crust with balanced umami and robust seasoning. This method optimizes smoke absorption and caramelization, resulting in a richly textured, savory crust that amplifies the overall taste experience.

Microflora-enhanced crust

Dry-aged mold rubs create a complex microflora-enhanced crust that intensifies flavor development through natural enzymatic activity and microbial fermentation, unlike conventional rubs that primarily rely on surface seasoning; this unique microflora promotes deeper umami notes and a more pronounced savory crust essential in high-quality smoked meats. The diverse microbial population from dry-aging molds forms a protective barrier that enhances moisture retention and texture, resulting in a richly aromatic, tender crust unattainable by traditional rub applications.

Conventional rub vs dry-aged mold rub for crust. Infographic

cookingdiff.com

cookingdiff.com