Hot smoking infuses food with rich, smoky flavors while simultaneously cooking it, resulting in tender and flavorful dishes such as smoked sausages or brisket. Cold smoking imparts a subtler smoky aroma without cooking the food, enhancing the natural flavors of items like salmon or cheese while preserving their texture. Both methods use controlled temperatures and wood smoke to develop distinct flavor profiles, catering to different culinary preferences.

Table of Comparison

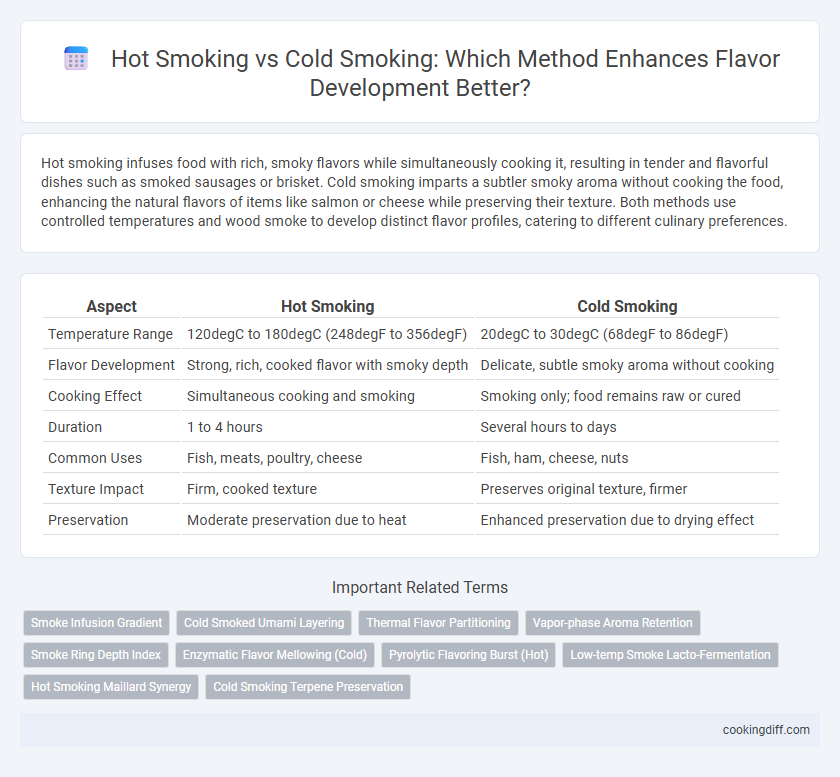

| Aspect | Hot Smoking | Cold Smoking |

|---|---|---|

| Temperature Range | 120degC to 180degC (248degF to 356degF) | 20degC to 30degC (68degF to 86degF) |

| Flavor Development | Strong, rich, cooked flavor with smoky depth | Delicate, subtle smoky aroma without cooking |

| Cooking Effect | Simultaneous cooking and smoking | Smoking only; food remains raw or cured |

| Duration | 1 to 4 hours | Several hours to days |

| Common Uses | Fish, meats, poultry, cheese | Fish, ham, cheese, nuts |

| Texture Impact | Firm, cooked texture | Preserves original texture, firmer |

| Preservation | Moderate preservation due to heat | Enhanced preservation due to drying effect |

Introduction to Smoking: Hot vs Cold Techniques

Hot smoking cooks food at temperatures between 165degF and 250degF, infusing it with rich, smoky flavors while simultaneously cooking it through. Cold smoking, performed at temperatures below 90degF, imparts a delicate smoke flavor without cooking, preserving the texture and moisture of the food. Both techniques rely on controlled smoke exposure from hardwoods like hickory or applewood to develop unique flavor profiles prized in culinary applications.

The Science of Flavor Development in Smoking

Hot smoking cooks food at temperatures between 165degF and 250degF, promoting Maillard reactions that develop complex savory flavors and caramelization. Cold smoking, done below 90degF, imparts smoke compounds without cooking, preserving natural textures while enhancing aromatic profiles through phenolic and aldehyde absorption.

The chemistry of hot smoking drives flavor through heat-induced protein denaturation and lipid oxidation, intensifying umami and smoky notes. In contrast, cold smoking relies on prolonged smoke exposure, allowing slower penetration of volatile organic compounds that enrich subtle smoky essences without altering food structure.

Hot Smoking Process: Temperature, Methods, and Impact

Hot smoking involves cooking food at temperatures between 165degF and 250degF, allowing flavors to penetrate deeply while simultaneously cooking. This method uses direct heat sources such as smokers or grills, which impart a robust smoky taste and tender texture.

- Temperature range - Hot smoking typically occurs between 165degF and 250degF to ensure proper cooking and flavor infusion.

- Methods - Common techniques include using charcoal smokers, electric smokers, or gas grills with wood chips for smoke generation.

- Impact on flavor - The higher temperature caramelizes surface sugars and proteins, resulting in a rich, smoky flavor and improved texture.

Hot smoking not only preserves food but also enhances its flavor by combining cooking and smoke infusion in one process.

Cold Smoking Process: Temperature, Methods, and Impact

Cold smoking typically occurs at temperatures between 68degF and 86degF (20degC and 30degC), allowing smoke to flavor food without cooking it. This low-temperature method preserves texture and infuses delicate smoky notes over extended periods.

- Temperature Range - Cold smoking maintains temperatures below 90degF (32degC) to prevent cooking and enable prolonged smoke exposure.

- Methods Employed - Techniques include the use of smoke generators or separate smoking chambers that keep heat away from the food.

- Flavor Impact - The slow smoke absorption enhances complexity, contributing subtle, nuanced smoky flavors ideal for fish, cheese, and cured meats.

Key Differences in Flavor Profiles: Hot vs Cold Smoking

How do hot smoking and cold smoking differ in flavor development? Hot smoking imparts a rich, smoky flavor while simultaneously cooking the food, enhancing moisture retention and tenderness. Cold smoking introduces a delicate, subtle smokiness without cooking, preserving the food's original texture and allowing for longer preservation.

Choosing the Right Woods for Hot and Cold Smoking

Choosing the right wood is crucial for flavor development in both hot smoking and cold smoking processes. Hardwoods like hickory, oak, and apple are preferred for hot smoking due to their ability to produce intense, robust flavors at higher temperatures, while milder woods such as alder, cherry, and maple are ideal for the delicate nature of cold smoking. Each wood type imparts unique aromatic compounds that enhance the taste profile of smoked meats and fish, making wood selection a key factor in achieving desired flavor nuances.

Suitable Foods for Hot Smoking vs Cold Smoking

Hot smoking is ideal for tougher meats like brisket, ribs, and whole poultry, as the higher temperatures (165-250degF) effectively cook and infuse them with smoky flavors. This method suits fish varieties such as salmon and mackerel that benefit from both cooking and flavor development.

Cold smoking is better suited for delicate foods like cheese, nuts, and cured meats, which are preserved without heat exposure at temperatures below 90degF. It enhances flavor complexity in items like ham, bacon, and sausages, where smoking occurs without altering texture through cooking.

Texture and Moisture: Effects on Food by Smoking Type

| Hot Smoking | Hot smoking applies temperatures between 165degF to 250degF, enhancing flavor while cooking and tenderizing food, resulting in a moist and flaky texture. The heat denatures proteins and breaks down connective tissues, preserving moisture content and creating a succulent bite. This method is ideal for meats and fish requiring both cooking and smoky aroma development. |

| Cold Smoking | Cold smoking occurs below 90degF, imparting smoky flavor without cooking, which maintains the original texture and moisture levels of food. It dehydrates the surface slightly, intensifying firmness and preserving internal moisture, making it suitable for delicate items like cheese, nuts, and cured meats. The lower temperature helps retain structural integrity while infusing subtle smoky nuances. |

Safety Considerations: Hot Smoking and Cold Smoking

Hot smoking cooks food at temperatures between 165degF and 185degF, reducing the risk of bacterial contamination by reaching safe internal temperatures. Cold smoking imparts flavor at temperatures below 90degF but requires additional curing or refrigeration to prevent pathogen growth.

- Hot smoking safety - The high heat effectively kills harmful bacteria, making the food safer for immediate consumption.

- Cold smoking risks - Lower temperatures do not cook the food, increasing the risk of foodborne pathogens if not properly handled.

- Storage requirements - Cold smoked foods must be refrigerated or frozen promptly to inhibit bacterial growth and maintain safety.

Related Important Terms

Smoke Infusion Gradient

Hot smoking infuses flavor more intensely due to higher temperatures causing deeper smoke penetration and rapid Maillard reactions, creating complex, robust tastes. Cold smoking generates a gentler smoke infusion gradient, resulting in subtle, layered flavors preserved through lower temperatures and extended exposure times.

Cold Smoked Umami Layering

Cold smoking preserves delicate umami compounds by exposing foods to smoke at temperatures below 90degF, allowing slow absorption of smoky flavors without cooking. This method enhances complex flavor layering through subtle phenol and aldehyde infusion, creating rich savory profiles ideal for fish, cheese, and cured meats.

Thermal Flavor Partitioning

Hot smoking rapidly infuses food with smoky flavors through higher temperatures that cause Maillard reactions, enhancing thermal flavor partitioning by promoting the release and interaction of volatile compounds. Cold smoking, occurring at lower temperatures, preserves more delicate aromatic compounds by minimizing thermal degradation, resulting in a subtler, nuanced flavor profile with different volatile partitioning dynamics.

Vapor-phase Aroma Retention

Hot smoking enhances flavor development by promoting Maillard reactions and smoke absorption, but it can lead to lower vapor-phase aroma retention due to higher temperatures causing volatile compound loss. Cold smoking preserves delicate vapor-phase aromas by operating at lower temperatures, allowing greater retention of smoke-derived aromatic compounds essential for nuanced flavor profiles.

Smoke Ring Depth Index

Hot smoking enhances flavor development by generating a deeper Smoke Ring Depth Index due to higher temperatures facilitating nitric oxide diffusion into the meat. Cold smoking, while preserving delicate textures, results in a shallower smoke ring as lower temperatures limit smoke penetration and nitric oxide binding.

Enzymatic Flavor Mellowing (Cold)

Cold smoking enhances flavor development through enzymatic flavor mellowing, a process where low temperatures allow enzymes to break down proteins and fats gradually, creating complex, subtle taste profiles. Unlike hot smoking, which imparts stronger, charred flavors, cold smoking preserves delicate nuances by maintaining enzymatic activity without cooking the food.

Pyrolytic Flavoring Burst (Hot)

Hot smoking generates a pyrolytic flavoring burst through high temperatures that cause the breakdown of lignin and cellulose in wood, producing complex smoky phenols, guaiacol, and syringol compounds that deeply infuse the food. This intense heat-driven chemical reaction creates robust, bold flavors distinct from cold smoking, which imparts a milder, surface-level smoke aroma without significant pyrolytic transformation.

Low-temp Smoke Lacto-Fermentation

Low-temp smoke lacto-fermentation combines cold smoking at temperatures below 90degF (32degC) with the fermentation process driven by lactic acid bacteria, enhancing flavor complexity through smoke absorption and acidification. This method preserves delicate textures and develops nuanced smoky, tangy notes ideal for producing artisanal cured meats and fish.

Hot Smoking Maillard Synergy

Hot smoking enhances flavor development through the Maillard reaction, generating complex, savory notes by combining heat and smoke that chemically transform proteins and sugars in the food. This Maillard synergy differentiates hot smoking from cold smoking, which imparts smoke flavor without significant heat-induced browning or flavor complexity.

Hot smoking vs cold smoking for flavor development. Infographic

cookingdiff.com

cookingdiff.com