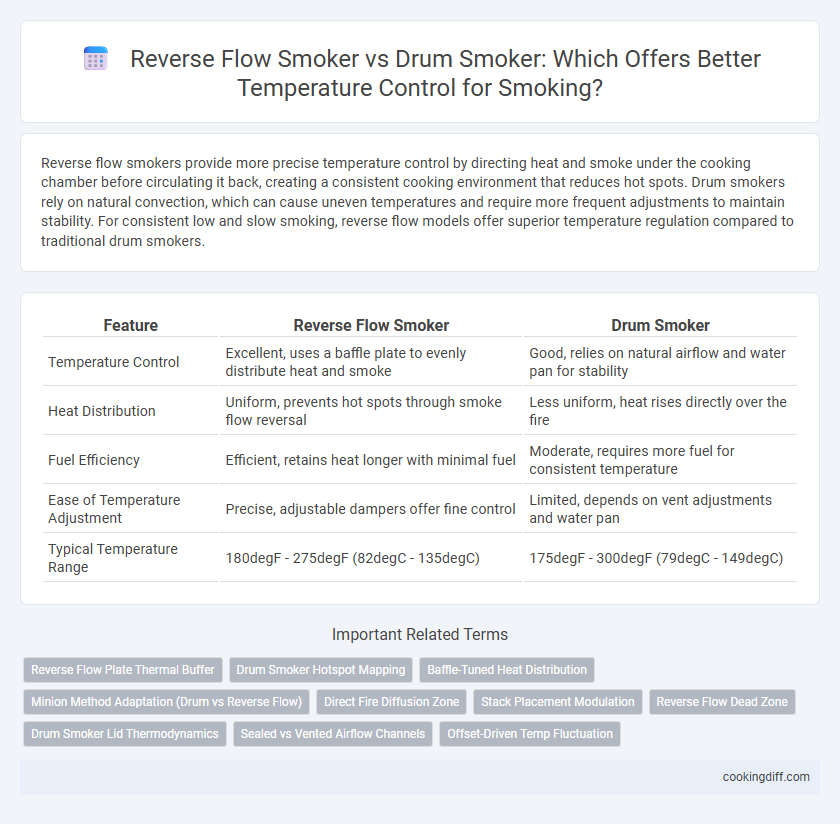

Reverse flow smokers provide more precise temperature control by directing heat and smoke under the cooking chamber before circulating it back, creating a consistent cooking environment that reduces hot spots. Drum smokers rely on natural convection, which can cause uneven temperatures and require more frequent adjustments to maintain stability. For consistent low and slow smoking, reverse flow models offer superior temperature regulation compared to traditional drum smokers.

Table of Comparison

| Feature | Reverse Flow Smoker | Drum Smoker |

|---|---|---|

| Temperature Control | Excellent, uses a baffle plate to evenly distribute heat and smoke | Good, relies on natural airflow and water pan for stability |

| Heat Distribution | Uniform, prevents hot spots through smoke flow reversal | Less uniform, heat rises directly over the fire |

| Fuel Efficiency | Efficient, retains heat longer with minimal fuel | Moderate, requires more fuel for consistent temperature |

| Ease of Temperature Adjustment | Precise, adjustable dampers offer fine control | Limited, depends on vent adjustments and water pan |

| Typical Temperature Range | 180degF - 275degF (82degC - 135degC) | 175degF - 300degF (79degC - 149degC) |

Introduction to Reverse Flow and Drum Smokers

Reverse flow smokers and drum smokers offer distinct methods for temperature regulation during smoking. Understanding their design differences is key to mastering temperature control technique.

- Reverse flow smoker - Features a baffle plate directing heat and smoke under the cooking chamber before reversing direction for even cooking and consistent temperature.

- Drum smoker - Uses a vertical drum shape with a charcoal basket at the bottom and a vent system to control airflow and temperature.

- Temperature control - Reverse flow smokers provide more precise temperature management due to heat distribution, while drum smokers rely on airflow adjustments for maintaining heat levels.

Choosing between a reverse flow and a drum smoker depends on user preference for temperature control style and cooking outcomes.

How Temperature Control Differs in Reverse Flow Smokers

Reverse flow smokers maintain temperature by circulating heat and smoke under a sealed baffle, promoting even heat distribution. Drum smokers rely on adjustable vents to regulate airflow but often experience hot spots due to less controlled heat flow.

- Heat distribution - Reverse flow smokers use a baffled plate to evenly distribute heat throughout the cooking chamber.

- Temperature consistency - The sealed design minimizes temperature fluctuations common in drum smokers.

- Airflow management - Reverse flow smokers control airflow internally, reducing the need for constant vent adjustments.

Temperature Management in Drum Smokers Explained

Drum smokers offer superior temperature control through their vertical design, which promotes even heat distribution and consistent airflow. Unlike reverse flow smokers that require frequent adjustments to maintain stable temperatures, drum smokers rely on adjustable dampers and charcoal placement to regulate heat effectively. This precise temperature management in drum smokers enhances smoke penetration and produces tender, flavorful meat.

Heat Distribution: Reverse Flow vs Drum Smoker

Reverse flow smokers offer more even heat distribution by channeling heat under a baffle plate before it reaches the cooking chamber, reducing hot spots. Drum smokers tend to have less consistent heat, often creating temperature variations near the firebox and cooking grates.

- Reverse Flow Design - The baffle plate in reverse flow smokers redirects heat and smoke, promoting uniform cooking temperatures across the rack.

- Drum Smoker Heat Zones - Drum smokers typically develop distinct heat zones with higher temperatures near the fire, causing uneven cooking.

- Temperature Control - Reverse flow smokers generally require less frequent adjustment to maintain steady temperatures compared to drum smokers.

Stability of Cooking Temperatures in Both Smokers

| Smoker Type | Temperature Stability | Control Mechanism |

|---|---|---|

| Reverse Flow Smoker | High stability due to indirect heat distribution and insulated metal baffle | Uses sealed firebox and reverse flow design to maintain consistent cooking temperatures between 200degF to 275degF |

| Drum Smoker | Moderate stability with some temperature fluctuations | Relies on adjustable vents and charcoal management but less insulation results in variable heat control |

Airflow Mechanisms and Their Impact on Temperature

Reverse flow smokers utilize a baffle system to redirect hot air and smoke from the firebox under the cooking chamber, promoting even heat distribution and minimizing temperature fluctuations. This airflow mechanism ensures consistent temperature control by preventing hot spots and allowing smoke to circulate evenly around the food.

Drum smokers rely on large, vertical cylindrical chambers with a firebox at the bottom, where heat rises directly through the cooking grates. Their simpler airflow system can lead to less precise temperature regulation, as air tends to flow unevenly, causing potential hotspots and temperature swings during long cooks.

Ease of Temperature Adjustments: Side-by-Side Comparison

Reverse flow smokers provide enhanced temperature control by directing heat and smoke uniformly across the cooking chamber, reducing hotspots and allowing for more consistent heat distribution. Their design includes internal baffles that improve airflow and make fine-tuning the temperature easier through adjustable dampers.

Drum smokers rely on a vertical setup where heat rises from the bottom, often requiring more frequent adjustments to maintain steady temperatures, especially in windy conditions. While simpler in construction, drum smokers typically demand more hands-on management of vents and fuel placement for effective temperature control.

Fuel Efficiency and Temperature Stability

Reverse flow smokers excel in temperature stability due to their unique design that evenly distributes heat and smoke, reducing hot spots. This design enhances fuel efficiency by allowing better control of airflow and a slower, more consistent burn.

Drum smokers, while simpler, can experience more temperature fluctuations because heat is concentrated directly under the cooking area. They tend to consume fuel faster as they require frequent adjustments to maintain optimal temperature. However, with proper management, drum smokers can still deliver satisfactory temperature control for longer cooking sessions.

Practical Tips for Better Temperature Control

Reverse flow smokers offer enhanced temperature stability through their design, which directs heat and smoke under a baffle before reaching the cooking chamber, reducing temperature fluctuations. Drum smokers require frequent monitoring and adjustments due to their direct heat source, making temperature control more challenging for beginners. Using water pans and adjusting air vents systematically can improve temperature consistency in both smoker types for better smoking results.

Related Important Terms

Reverse Flow Plate Thermal Buffer

The reverse flow smoker incorporates a reverse flow plate that acts as a thermal buffer, evenly distributing heat and minimizing temperature fluctuations, whereas the drum smoker relies on a more direct heat source with less temperature regulation. This thermal buffer in reverse flow smokers enhances consistent cooking conditions, making it easier to maintain steady smoke temperature over long cooking sessions.

Drum Smoker Hotspot Mapping

Drum smokers exhibit more consistent temperature control due to their vertical design, minimizing hotspots typically found in reverse flow smokers where heat travels horizontally and can create uneven cooking zones. Hotspot mapping in drum smokers reveals a concentrated heat source near the charcoal chamber at the bottom, promoting even smoke circulation and stable cooking temperatures throughout the vertical smoking chamber.

Baffle-Tuned Heat Distribution

Reverse flow smokers utilize an internal baffle that directs heat and smoke under and back across the cooking chamber, ensuring even temperature control and consistent heat distribution. Drum smokers lack a baffle system, relying on natural convection that can result in less precise temperature regulation and hot spots.

Minion Method Adaptation (Drum vs Reverse Flow)

Reverse flow smokers offer more consistent temperature control by evenly distributing heat and smoke through a baffle system, making Minion Method adaptation smoother and reducing temperature spikes. Drum smokers, while effective with the Minion Method, require more frequent monitoring due to concentrated heat zones, potentially causing less stable temperature management compared to reverse flow designs.

Direct Fire Diffusion Zone

Reverse flow smokers excel in temperature control by directing heat and smoke evenly through the direct fire diffusion zone, reducing hot spots and ensuring consistent heat distribution. Drum smokers, while simpler, often struggle with maintaining steady temperatures in the direct fire diffusion zone due to less efficient airflow management, leading to temperature fluctuations.

Stack Placement Modulation

Reverse flow smokers feature a strategically placed internal baffle that directs heat and smoke underneath the cooking chamber before it rises, enabling more consistent temperature control through optimized stack placement modulation. Drum smokers rely on vertical airflow with the stack positioned at the top, which can lead to less precise temperature regulation compared to the horizontal heat circulation in reverse flow models.

Reverse Flow Dead Zone

Reverse flow smokers minimize the reverse flow dead zone by pushing heat and smoke under a sealed baffle, promoting even temperature distribution and consistent airflow. Drum smokers often experience a larger dead zone where heat stagnates, leading to less precise temperature control and uneven cooking.

Drum Smoker Lid Thermodynamics

Drum smokers offer superior temperature control due to their efficient lid thermodynamics, which maintain consistent heat by minimizing heat loss and promoting even air circulation. In contrast, reverse flow smokers can experience greater temperature fluctuations as their design relies on airflow paths that are more susceptible to external temperature changes.

Sealed vs Vented Airflow Channels

Reverse flow smokers feature sealed airflow channels that enable more precise temperature control by directing heat and smoke evenly through the cooking chamber, minimizing temperature fluctuations. In contrast, drum smokers utilize vented airflow channels, which allow for greater airflow adjustments but can result in less consistent temperature stability during long smoking sessions.

Reverse flow smoker vs drum smoker for temperature control. Infographic

cookingdiff.com

cookingdiff.com