Traditional barbecue involves direct heat and smoke exposure, often resulting in a smokier, more intense flavor, but can cause uneven cooking or flare-ups. Reverse flow smoking uses a baffle to circulate heat and smoke back across the meat before exiting, promoting even cooking and consistent smoke absorption. This method reduces temperature fluctuations, making it ideal for larger cuts requiring long, slow smoking sessions.

Table of Comparison

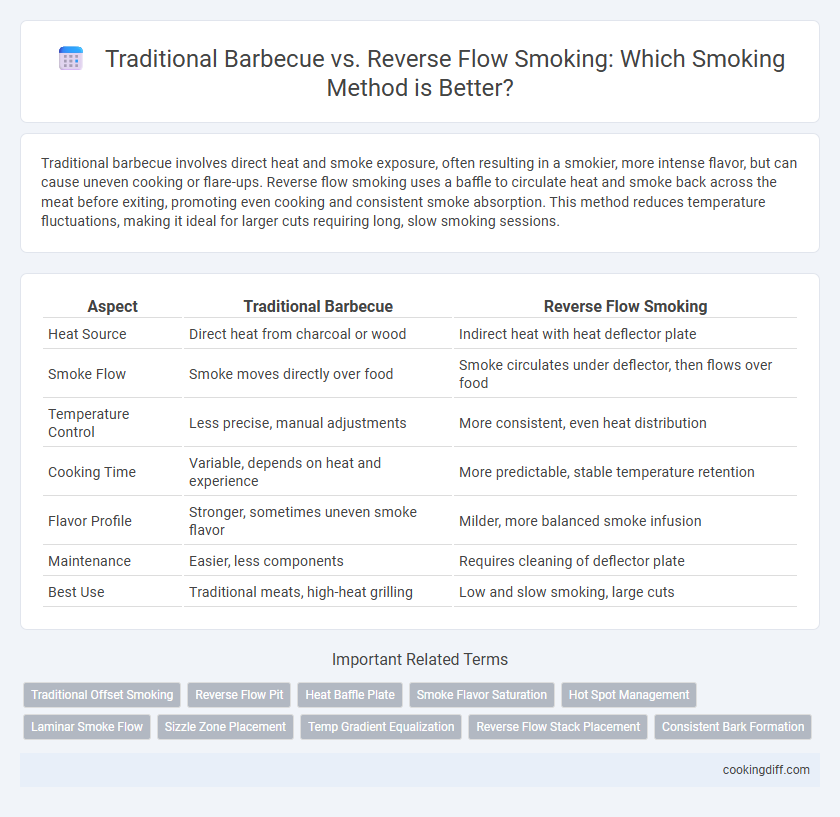

| Aspect | Traditional Barbecue | Reverse Flow Smoking |

|---|---|---|

| Heat Source | Direct heat from charcoal or wood | Indirect heat with heat deflector plate |

| Smoke Flow | Smoke moves directly over food | Smoke circulates under deflector, then flows over food |

| Temperature Control | Less precise, manual adjustments | More consistent, even heat distribution |

| Cooking Time | Variable, depends on heat and experience | More predictable, stable temperature retention |

| Flavor Profile | Stronger, sometimes uneven smoke flavor | Milder, more balanced smoke infusion |

| Maintenance | Easier, less components | Requires cleaning of deflector plate |

| Best Use | Traditional meats, high-heat grilling | Low and slow smoking, large cuts |

Introduction to Smoking Methods: Traditional Barbecue vs Reverse Flow

Traditional barbecue and reverse flow smoking are two popular methods for achieving distinct flavors and cooking results. Both techniques use indirect heat and smoke to cook meat slowly, but their approach to heat distribution varies significantly.

- Traditional barbecue - relies on a natural airflow system where heat and smoke flow directly across the meat before exiting the smoker.

- Reverse flow smoking - uses a baffle plate to circulate heat and smoke under the meat and then back across, promoting even cooking.

- Flavor profile - traditional barbeque often imparts a stronger smoke ring, while reverse flow tends to provide more consistent temperature control.

Choosing between traditional and reverse flow smoking depends on desired flavor complexity, temperature control, and cooking consistency.

How Traditional Barbecue Smoking Works

| Method | Traditional Barbecue Smoking |

| Process | Smoke is generated from a firebox and flows directly into the cooking chamber, where it surrounds the meat, imparting flavor. Heat and smoke move in a straight line from the fire source to the exhaust, creating a consistent, low-temperature cooking environment. |

| Advantages | Simple design with fewer mechanical components allows for easier operation and maintenance. Ideal for producing deep smoky flavors due to longer smoke exposure on the meat surface. |

Reverse Flow Smoking Explained

Reverse flow smoking uses a baffle system to direct heat and smoke under a metal plate before reaching the food, creating a more even temperature distribution compared to traditional barbecue methods. This method reduces hot spots and maintains consistent heat, resulting in juicier, more evenly cooked meat.

Traditional barbecue relies on direct heat and open airflow, often causing uneven cooking zones that can burn or dry out meat. Reverse flow smokers improve smoke penetration by circulating flavorful smoke across the cooking chamber twice, enhancing taste while minimizing flare-ups. The design also simplifies temperature control, making it a preferred choice for serious pitmasters aiming for precision and efficiency.

Heat Distribution: Comparing Methods

Traditional barbecue relies on direct heat from a single fire source, creating distinct hot and cool zones ideal for quick cooking and searing. Heat distribution can be uneven, requiring frequent adjustments to avoid flare-ups and ensure consistent cooking.

Reverse flow smoking utilizes a baffle system that directs heat and smoke under a sealed metal plate before reaching the cooking chamber, promoting more even heat distribution. This method maintains a stable temperature throughout the smoker, improving smoke penetration and cooking consistency for low and slow barbecue.

Smoke Flavor Profile Differences

Traditional barbecue smoking produces a robust smoke flavor with pronounced woodiness and a slightly bitter undertone due to direct exposure to smoke and heat. Reverse flow smoking offers a more balanced and milder smoke flavor by circulating heat and smoke evenly, reducing harshness and enhancing meat tenderness. The choice between methods significantly impacts the complexity and intensity of the smoke profile in smoked meats.

Temperature Control and Consistency

Traditional barbecue smokers rely on passive airflow which can cause fluctuating temperatures, making precise control challenging. Reverse flow smokers channel heat and smoke under a sealed baffle, promoting even heat distribution and consistent cooking temperatures.

- Temperature Control - Reverse flow smokers maintain steadier heat by forcing smoke and heat to travel across the meat before exiting.

- Consistency - Traditional smokers may produce hot spots, whereas reverse flow designs ensure uniform heat dispersal throughout the cooking chamber.

- Fuel Efficiency - Reverse flow systems optimize charcoal or wood usage by maximizing heat retention and minimizing temperature swings.

Fuel Efficiency: Traditional vs Reverse Flow

Reverse flow smoking offers improved fuel efficiency by circulating heat and smoke evenly, reducing wood consumption compared to traditional barbecue methods. Traditional smoking often requires more frequent fuel replenishment due to uneven heat distribution.

- Reverse flow smoking conserves fuel - By directing heat across the cooking chamber, it maximizes wood burn time and heat utilization.

- Traditional barbecue can be less efficient - Hot spots and uneven airflow increase fuel use to maintain consistent cooking temperatures.

- Consistent temperature control in reverse flow - Minimizes the need for additional fuel to adjust heat fluctuations during smoking.

Equipment Setup and Maintenance

What are the key differences in equipment setup between traditional barbecue and reverse flow smoking methods? Traditional barbecue requires a straightforward firebox and cooking chamber alignment, while reverse flow smokers incorporate a baffle that directs heat and smoke under the cooking grate for even distribution. Maintenance of reverse flow smokers often involves more frequent cleaning of the baffle system to prevent grease buildup compared to the simpler design of traditional setups.

Best Foods for Each Smoking Method

Traditional barbecue smoking excels with larger, tougher cuts like brisket, pork shoulder, and ribs, as the indirect heat and smoke slowly tenderize the meat over several hours. This method enhances the rich, smoky flavor and creates a desirable bark on the exterior.

Reverse flow smoking is ideal for delicate foods such as poultry and fish, offering even heat distribution and consistent smoke circulation that prevents flare-ups and scorching. It also works well for vegetables, unlocking complex smoky notes while maintaining moisture and texture.

Related Important Terms

Traditional Offset Smoking

Traditional offset smoking relies on a firebox positioned beside the main cooking chamber, allowing smoke and heat to flow horizontally through the meat, providing a distinct smoky flavor and bark formation. This method requires constant temperature monitoring and control, making it ideal for experienced pitmasters seeking authentic, hands-on barbecue techniques.

Reverse Flow Pit

Reverse flow pits enhance smoking by directing heat evenly across the meat through a sealed baffle that routes hot air under the cooking surface before it rises, preventing flare-ups and ensuring consistent low-and-slow temperatures. Compared to traditional barbecue methods, reverse flow smoking delivers more uniform heat distribution, reduced temperature fluctuations, and improved smoke flavor infusion, making it ideal for large cuts like brisket and ribs.

Heat Baffle Plate

The heat baffle plate in traditional barbecue smokers disperses heat unevenly, often causing hot spots that can lead to inconsistent cooking results. In contrast, reverse flow smokers use a heat baffle plate designed to channel heat and smoke evenly across the cooking chamber, promoting uniform temperature distribution and improved smoke flavor penetration.

Smoke Flavor Saturation

Traditional barbecue uses indirect heat with smoke flowing in one direction, producing a lighter smoke flavor saturation, while reverse flow smokers circulate heat and smoke evenly through a baffle, resulting in deeper, more consistent smoke flavor absorption throughout the meat. Reverse flow smoking enhances flavor saturation by preventing hot spots and ensuring longer smoke exposure compared to traditional methods.

Hot Spot Management

Traditional barbecue often struggles with uneven heat distribution, creating hot spots that can cause inconsistent cooking, whereas reverse flow smokers use a baffle system to direct heat and smoke evenly across the cooking chamber. This design significantly improves hot spot management, ensuring more uniform temperature control for better meat quality and consistent results.

Laminar Smoke Flow

Traditional barbecue relies on direct heat and smoke exposure, often resulting in uneven smoke distribution, while reverse flow smoking utilizes a baffled, reverse flow design to create laminar smoke flow, ensuring consistent heat and smoke contact throughout the cooking chamber. This controlled laminar smoke flow enhances flavor infusion, tenderness, and overall cooking efficiency by preventing hot spots and promoting even smoke circulation over the meat.

Sizzle Zone Placement

Traditional barbecue places the sizzle zone directly above the heat source, creating intense, direct heat ideal for searing but prone to flare-ups and uneven cooking. Reverse flow smoking's sizzle zone is offset and separated by a baffle, promoting indirect heat distribution that reduces flare-ups, maintains consistent temperature, and enhances smoke penetration for more even cooking results.

Temp Gradient Equalization

Reverse flow smoking achieves superior temperature gradient equalization by circulating heat evenly across the cooking chamber, minimizing hotspots typical in traditional barbecue smokers. This method ensures consistent cooking temperatures and uniform smoke penetration, enhancing meat flavor and texture.

Reverse Flow Stack Placement

Reverse flow smoking enhances flavor and temperature control by directing heat and smoke under a sealed baffle plate, allowing even distribution throughout the cooking chamber. The reverse flow stack placement positioned at the same end as the firebox forces heat and smoke to travel beneath the cooking surface, promoting consistent cooking and reducing flare-ups compared to traditional barrel or offset smokers.

Traditional barbecue vs reverse flow smoking for method. Infographic

cookingdiff.com

cookingdiff.com