Traditional smokers use direct heat and smoke to cook and preserve foods, producing rich flavors but often involving higher temperatures that can alter delicate textures. Cold smoke generators create smoke without significant heat, ideal for preserving pet treats by extending shelf life while maintaining nutritional value and texture. For preserving pet products, cold smoke generators offer a gentler, more controlled smoking process that minimizes cooking and retains essential qualities.

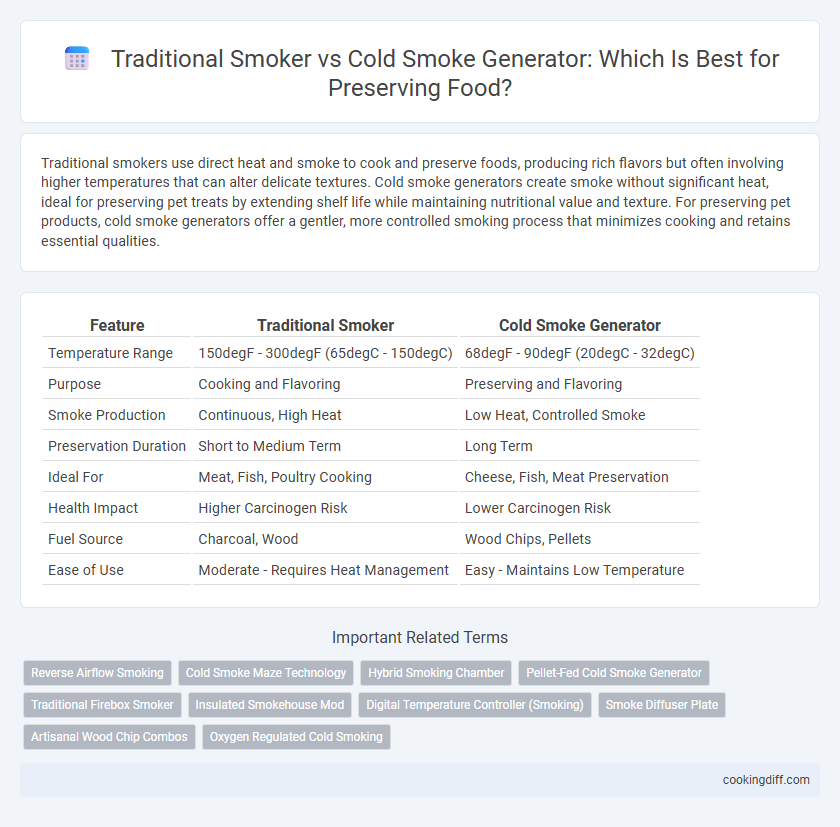

Table of Comparison

| Feature | Traditional Smoker | Cold Smoke Generator |

|---|---|---|

| Temperature Range | 150degF - 300degF (65degC - 150degC) | 68degF - 90degF (20degC - 32degC) |

| Purpose | Cooking and Flavoring | Preserving and Flavoring |

| Smoke Production | Continuous, High Heat | Low Heat, Controlled Smoke |

| Preservation Duration | Short to Medium Term | Long Term |

| Ideal For | Meat, Fish, Poultry Cooking | Cheese, Fish, Meat Preservation |

| Health Impact | Higher Carcinogen Risk | Lower Carcinogen Risk |

| Fuel Source | Charcoal, Wood | Wood Chips, Pellets |

| Ease of Use | Moderate - Requires Heat Management | Easy - Maintains Low Temperature |

Understanding Traditional Smokers: Basics and Benefits

Traditional smokers use direct heat and smoke to preserve and flavor food, offering a rich, smoky taste through controlled wood combustion. They typically operate at higher temperatures, allowing for both preservation and cooking processes simultaneously.

- Heat Source - Direct heat from burning wood or charcoal helps cook and infuse food with smoky flavors.

- Temperature Range - Operates generally between 225degF and 275degF, suitable for smoking meats and fish.

- Flavor Profile - Produces robust, intense smoky flavors that enhance preservation and taste.

Traditional smokers remain a popular choice for artisanal food preservation due to their authentic smoke infusion and versatility.

What is a Cold Smoke Generator? Functionality Explained

Cold smoke generators produce smoke at low temperatures, typically below 90degF (32degC), allowing food preservation without cooking. Traditional smokers use higher heat, combining smoke flavor with cooking or curing the food.

- Cold Smoke Generator Function - It slowly burns wood chips or pellets to create smoke without raising the temperature significantly.

- Temperature Control - Maintains consistent low heat to prevent food from cooking while infusing smoky flavors.

- Preservation Benefit - Ideal for delicate foods like cheese, fish, and meats that need flavor and preservation without heat damage.

Key Differences: Traditional Smoker vs Cold Smoke Generator

What are the key differences between a traditional smoker and a cold smoke generator for preserving food? Traditional smokers use high heat, typically between 225degF and 300degF, to cook and flavor food simultaneously, which can alter texture and moisture content. Cold smoke generators operate at much lower temperatures, usually below 90degF, allowing smoke to infuse foods without cooking, ideal for preserving delicate items like cheese and fish.

The Science of Smoke: How Preservation Occurs

Traditional smokers use direct heat and smoke from burning wood to preserve food by dehydrating and applying phenolic compounds, which inhibit bacterial growth. Cold smoke generators operate at lower temperatures, producing smoke that imparts antimicrobial and antioxidant compounds without cooking the food, thus preserving texture and nutrients. The chemical interaction of smoke phenols, formaldehyde, and organic acids creates a protective barrier that extends shelf life by reducing microbial activity and oxidation.

Flavor Profiles: Hot Smoking vs Cold Smoking

Traditional hot smoking involves cooking food at temperatures between 165degF to 185degF, which imparts a robust, smoky flavor while simultaneously cooking and preserving the food. In contrast, cold smoke generators produce smoke at temperatures below 90degF, allowing for longer exposure without cooking, thus preserving delicate flavors and enhancing complexity.

Hot smoking develops deeper, more intense smoky and roasted flavor profiles ideal for meats and fish, while cold smoking maintains the natural taste and texture of foods like cheese, nuts, and cured meats. Cold smoke infuses subtle woodsy aromas over extended periods, which complements rather than overpowers the original flavors. Both methods rely on different temperature controls to achieve distinct taste experiences in preserved foods.

Equipment and Setup: Ease of Use Compared

| Equipment Type | Setup Complexity | Ease of Use |

|---|---|---|

| Traditional Smoker | Requires fire management, ventilation control, and fuel selection, often involving a learning curve for temperature regulation. | Demands constant monitoring to maintain optimal smoking conditions and food flavor. |

| Cold Smoke Generator | Uses a compact device that produces smoke at low temperatures, simplifying setup with minimal adjustments. | Allows for steady, controlled smoke output with less frequent supervision, ideal for preserving delicate foods. |

Safety Considerations in Smoking Preservation

Traditional smokers rely on direct heat and smoke, which increases the risk of flare-ups and uneven temperature control, potentially compromising food safety. Cold smoke generators maintain a lower temperature, reducing the chance of bacterial growth while preserving flavor more safely.

Proper ventilation and monitoring are critical in both methods to prevent harmful smoke inhalation and maintain safe curing conditions. Cold smoke generators often incorporate built-in safety features that help regulate smoke output, minimizing fire hazards and chemical contaminants.

Best Foods for Traditional Smoking vs Cold Smoke Generation

Traditional smoking excels with fatty meats like brisket, pork shoulder, and salmon, where prolonged exposure to heat and smoke enhances flavor and tenderness. Cheese and nuts benefit more from cold smoke generators, which infuse smoky aromas without cooking or melting the food.

Cold smoke generation is ideal for delicate foods such as poultry, sausages, and cured fish, preserving texture while adding subtle smoky notes. Traditional smokers, using higher temperatures, are better suited for robust cuts and root vegetables that require thorough cooking alongside flavor development.

Energy Consumption and Cost Analysis

Traditional smokers consume significantly more energy, often relying on continuous wood or charcoal combustion, which can increase operational costs by up to 40% compared to cold smoke generators. Cold smoke generators use less fuel by maintaining lower, controlled temperatures, leading to reduced energy consumption and lower overall expenses. Cost analysis shows cold smoke units can save up to 30% in fuel and maintenance costs, making them a more economical option for long-term preserving.

Related Important Terms

Reverse Airflow Smoking

Reverse airflow smoking enhances flavor retention and moisture control compared to traditional smoking methods, offering a consistent temperature ideal for preserving meats. Cold smoke generators, unlike traditional smokers, produce smoke at lower temperatures without direct heat, preventing cooking and enabling longer preservation periods while maintaining the food's texture and nutritional value.

Cold Smoke Maze Technology

Cold Smoke Maze Technology enhances preservation by maintaining low temperatures and consistent smoke exposure, preventing moisture loss and bacterial growth better than traditional smokers. This advanced method ensures prolonged shelf life and richer flavor retention through controlled smoke diffusion and precise temperature regulation.

Hybrid Smoking Chamber

A hybrid smoking chamber combines the traditional smoker's intense heat with the cold smoke generator's low-temperature, prolonged exposure to smoke compounds, optimizing preservation by balancing flavor infusion and moisture retention. This integration enhances shelf life and nutrient preservation in meats and fish through controlled smoke density and temperature regulation, surpassing the limitations of either method alone.

Pellet-Fed Cold Smoke Generator

Traditional smokers rely on burning wood or charcoal, producing heat and smoke that can alter the texture and flavor of food, whereas pellet-fed cold smoke generators operate at low temperatures, producing consistent, clean smoke ideal for preserving delicate foods without cooking them. Pellet-fed cold smoke generators enhance preservation by maintaining a steady, low-temperature environment, preventing spoilage while infusing a mild smoky flavor that extends shelf life effectively.

Traditional Firebox Smoker

Traditional firebox smokers utilize direct heat and smoke from smoldering wood to preserve and flavor meats, creating a distinct smoky profile through slow cooking at controlled temperatures. Unlike cold smoke generators that produce smoke without heat for extended preservation, firebox smokers combine heat and smoke, enhancing tenderness and flavor while effectively curing products.

Insulated Smokehouse Mod

The Insulated Smokehouse Mod enhances preservation by maintaining consistent temperatures and optimal humidity compared to traditional smokers, which often struggle with heat fluctuations and uneven smoke distribution. Cold smoke generators integrated with this mod enable prolonged, low-temperature smoking that preserves delicate flavors and extends shelf life without cooking the food.

Digital Temperature Controller (Smoking)

Traditional smokers rely on manual adjustments to control temperature, often resulting in inconsistent smoking conditions, whereas cold smoke generators equipped with digital temperature controllers enable precise regulation of smoke temperature, enhancing preservation quality and safety. Digital temperature controllers maintain stable low-temperature environments ideal for cold smoking, preventing overheating and preserving the texture and flavor of delicate foods effectively.

Smoke Diffuser Plate

A smoke diffuser plate in traditional smokers enhances even smoke distribution, preventing flare-ups and ensuring consistent flavor absorption in preserved foods. Cold smoke generators use similar plates to maintain low temperatures while diffusing smoke gently, preserving the integrity and texture of delicate products during extended smoking sessions.

Artisanal Wood Chip Combos

Traditional smokers rely on direct heat and smoke from burning wood chips like hickory or mesquite, offering classic smoky flavors but often require constant monitoring to maintain temperature and smoke quality. Cold smoke generators use a low-temperature smoke source with artisanal wood chip combos such as apple and cherry wood, preserving delicate flavors in meats and cheeses by infusing smoke slowly without cooking the food.

Traditional smoker vs Cold smoke generator for preserving. Infographic

cookingdiff.com

cookingdiff.com