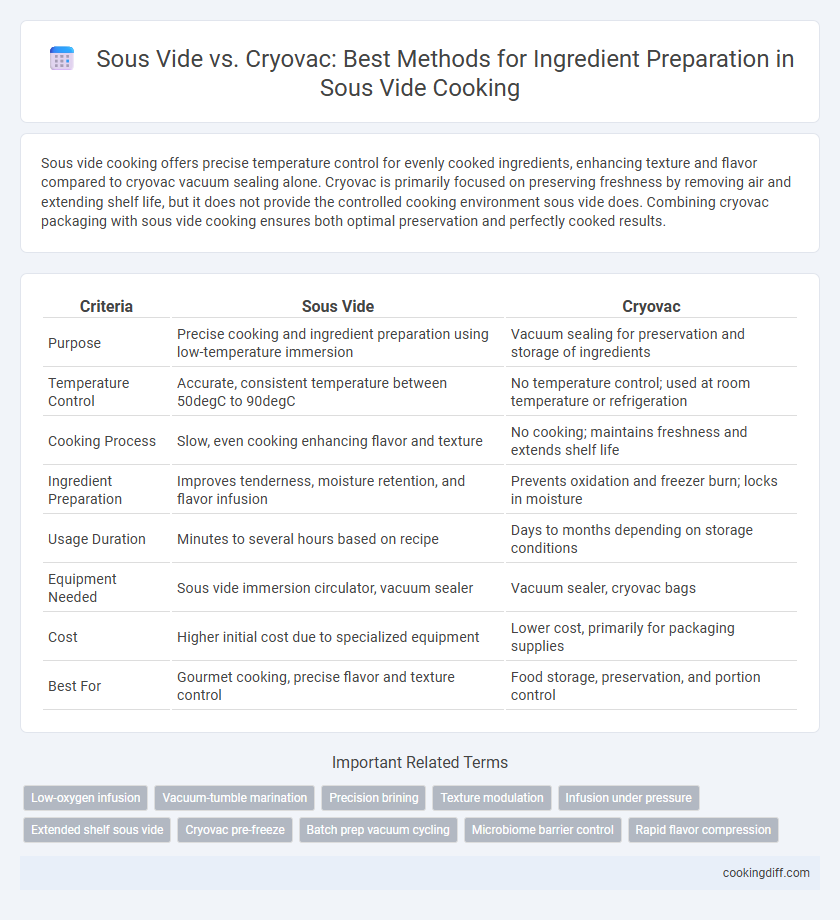

Sous vide cooking offers precise temperature control for evenly cooked ingredients, enhancing texture and flavor compared to cryovac vacuum sealing alone. Cryovac is primarily focused on preserving freshness by removing air and extending shelf life, but it does not provide the controlled cooking environment sous vide does. Combining cryovac packaging with sous vide cooking ensures both optimal preservation and perfectly cooked results.

Table of Comparison

| Criteria | Sous Vide | Cryovac |

|---|---|---|

| Purpose | Precise cooking and ingredient preparation using low-temperature immersion | Vacuum sealing for preservation and storage of ingredients |

| Temperature Control | Accurate, consistent temperature between 50degC to 90degC | No temperature control; used at room temperature or refrigeration |

| Cooking Process | Slow, even cooking enhancing flavor and texture | No cooking; maintains freshness and extends shelf life |

| Ingredient Preparation | Improves tenderness, moisture retention, and flavor infusion | Prevents oxidation and freezer burn; locks in moisture |

| Usage Duration | Minutes to several hours based on recipe | Days to months depending on storage conditions |

| Equipment Needed | Sous vide immersion circulator, vacuum sealer | Vacuum sealer, cryovac bags |

| Cost | Higher initial cost due to specialized equipment | Lower cost, primarily for packaging supplies |

| Best For | Gourmet cooking, precise flavor and texture control | Food storage, preservation, and portion control |

Understanding Sous Vide and Cryovac: Key Differences

What are the key differences between sous vide and cryovac for ingredient preparation? Sous vide involves vacuum-sealing food and cooking it at precise low temperatures, ensuring even cooking and enhanced flavor retention. Cryovac, primarily a vacuum-sealing method, extends shelf life by removing air but does not involve cooking, making it ideal for storage rather than preparation.

Precision Cooking: Sous Vide’s Temperature Control Advantage

Sous vide offers unparalleled precision in temperature control, maintaining exact heat levels within a fraction of a degree, which ensures consistent cooking results and preserves ingredient texture and flavor. In contrast, cryovac primarily focuses on vacuum sealing for preservation without temperature regulation during the cooking process.

Precise temperature control in sous vide cooking enables even heat distribution and prevents overcooking or undercooking, crucial for delicate proteins and vegetables. Cryovac packaging facilitates marination and extended shelf life but lacks the ability to cook ingredients at controlled temperatures. This temperature precision makes sous vide the preferred method for chefs aiming for culinary accuracy and optimal texture development.

Ingredient Shelf Life: Cryovac Sealing for Extended Freshness

Cryovac sealing significantly extends the shelf life of ingredients by creating an airtight environment that inhibits bacterial growth and oxidation. This vacuum-sealing method preserves freshness, texture, and flavor for weeks, making it ideal for long-term storage before sous vide cooking.

While sous vide enhances tenderness and flavor through precise temperature control during cooking, cryovac sealing focuses on preserving ingredient quality prior to preparation. Combining cryovac packaging with sous vide cooking maximizes ingredient longevity and culinary results.

Flavor and Texture: Impact of Sous Vide vs Cryovac Preparation

Sous vide cooking enhances flavor infusion and maintains an optimal texture by gently cooking ingredients in a precisely controlled water bath. Cryovac packaging preserves freshness but lacks the controlled temperature environment that allows sous vide to improve tenderness and flavor absorption.

- Flavor Enhancement - Sous vide ensures even seasoning penetration at low temperatures, intensifying natural flavors without overcooking.

- Texture Retention - Slow, controlled heat in sous vide prevents moisture loss, resulting in tender, consistently textured ingredients.

- Cryovac Limitations - Cryovac preserves freshness by vacuum sealing but does not affect flavor development or improve texture during cooking.

Vacuum Sealing Techniques: Sous Vide Needs vs Cryovac Methods

Vacuum sealing is critical in both sous vide and cryovac methods, but sous vide requires airtight seals to ensure precise temperature control and moisture retention during long cooking times. Cryovac sealing primarily focuses on preserving freshness and extending shelf life by removing air to prevent oxidation and spoilage.

- Sous vide sealing demands airtight, heat-resistant bags - These bags withstand extended immersion in water at controlled temperatures without leaking or compromising food quality.

- Cryovac uses thicker, more puncture-resistant films - Designed to protect ingredients during frozen storage and transport, preventing freezer burn and contamination.

- Vacuum pressure differs by purpose - Sous vide sealing often requires lower vacuum pressure to avoid crushing delicate ingredients, whereas cryovac systems maximize air removal for preservation.

Choosing the right vacuum sealing technique optimizes food quality depending on whether immersion cooking or long-term storage is required.

Cost and Equipment Requirements: Sous Vide vs Cryovac

| Aspect | Sous Vide | Cryovac |

|---|---|---|

| Cost | Initial investment for sous vide includes precision immersion circulators and vacuum sealers, typically ranging from $100 to $500. Long-term costs are moderate due to energy efficiency and reusable equipment. Food waste reduction and consistent cooking results can offset upfront expenses. | Cryovac machines vary widely in price, from affordable commercial vacuum sealers to industrial-grade systems exceeding $1,000. Consumables like vacuum bags add ongoing costs. Lower equipment investment but higher operational expenses due to consumables. |

| Equipment Requirements | Requires immersion circulator, heat-stable vacuum bags, and vacuum sealer. Precision temperature control enables consistent cooking, demanding reliable kitchen space with power access. Equipment is compact and suitable for both home and professional kitchens. | Primarily needs a vacuum sealer and compatible vacuum bags or rolls. Temperature control is not part of the equipment, as cryovac focuses on sealing and preservation. Equipment is generally simpler but lacks cooking capabilities. |

Food Safety Considerations in Sous Vide and Cryovac

Sous vide cooking maintains precise temperature control, typically between 55degC and 60degC, minimizing bacterial growth and ensuring safe pasteurization of ingredients. Cryovac sealing preserves freshness by vacuum-packing food, reducing oxygen exposure but requiring careful refrigeration to prevent anaerobic bacterial risks. Both methods enhance food safety when combined with proper temperature management and hygiene protocols during preparation and storage.

Workflow Efficiency: Prepping Ingredients with Sous Vide or Cryovac

Sous vide and cryovac offer distinct advantages in ingredient preparation, with sous vide providing precise temperature control that enhances consistency and tenderness. Cryovac streamlines storage and shelf life, reducing spoilage through vacuum sealing that limits oxygen exposure.

- Consistent Cooking - Sous vide maintains exact temperatures for uniform doneness across batches.

- Extended Freshness - Cryovac vacuum seals ingredients to prolong storage life effectively.

- Workflow Integration - Sous vide requires time-intensive cooking cycles, while cryovac supports rapid prep and storage workflows.

Recipe Versatility: Which Method Enhances More Dishes?

Sous vide offers greater recipe versatility by precisely controlling temperature and cooking times, enabling a wide range of textures and flavors unattainable with cryovac sealing alone. Cryovac primarily preserves freshness and extends shelf life but lacks the precise cooking control that sous vide provides for complex dishes. Chefs prefer sous vide for experimenting with proteins, vegetables, and delicate ingredients, enhancing culinary creativity beyond simple storage solutions.

Related Important Terms

Low-oxygen infusion

Sous vide cooking preserves ingredient flavor and texture through precise temperature control in a vacuum-sealed, low-oxygen environment, enhancing infusion by limiting oxidation. Cryovac packaging also removes air but lacks the temperature regulation of sous vide, resulting in less effective marinade absorption and nutrient retention during preparation.

Vacuum-tumble marination

Vacuum-tumble marination in sous vide enhances flavor penetration and tenderizes ingredients more effectively than traditional cryovac methods by applying consistent pressure and vacuum cycles. This technique ensures uniform marinade distribution, reducing marination time while preserving texture and moisture, essential for premium culinary results.

Precision brining

Sous vide offers precise temperature control for even brining, ensuring consistent salt penetration and moisture retention compared to cryovac sealing, which primarily preserves freshness without regulating the brining environment. Precision brining with sous vide enhances flavor absorption by maintaining optimal time and temperature parameters unavailable in standard cryovac methods.

Texture modulation

Sous vide technology ensures precise temperature control during cooking, allowing for consistent and uniform texture modulation in ingredients by gently breaking down proteins and fibers without overcooking. Cryovac, primarily used for vacuum sealing and preservation, lacks the controlled cooking environment needed to significantly alter texture, making sous vide superior for achieving desired tenderness and mouthfeel.

Infusion under pressure

Sous vide cooking uses precise temperature control to slowly infuse flavors into ingredients by vacuum-sealing them in a water bath, enhancing taste and texture without overcooking. Cryovac, while also vacuum-sealing, primarily preserves freshness but lacks the controlled heat environment necessary for effective pressure infusion of flavors during preparation.

Extended shelf sous vide

Sous vide cooking extends the shelf life of ingredients by vacuum-sealing them and cooking at precise low temperatures, preserving freshness and reducing spoilage compared to traditional cryovac packaging, which only removes air but does not regulate temperature. The controlled environment of sous vide inhibits bacterial growth and enzymatic activity, effectively doubling or tripling refrigerated shelf life versus standard cryovac storage methods.

Cryovac pre-freeze

Cryovac pre-freeze preserves ingredient freshness by sealing in moisture and preventing freezer burn, making it ideal for long-term storage before sous vide cooking. Sous vide cooking enhances texture and flavor by slowly cooking vacuum-sealed ingredients at precise temperatures, but Cryovac pre-freeze ensures optimal ingredient quality prior to the cooking process.

Batch prep vacuum cycling

Batch preparation using sous vide involves precise vacuum cycling that removes air to ensure even heat transfer and consistent cooking results, while cryovac techniques prioritize long-term preservation through tight vacuum sealing but lack the controlled temperature environment of sous vide. Sous vide's vacuum cycling enhances ingredient texture and flavor by minimizing oxidation and moisture loss during extended cooking periods, unlike cryovac which mainly maintains freshness for storage.

Microbiome barrier control

Sous vide cooking ensures precise temperature control to effectively eliminate harmful bacteria while preserving beneficial microbiome integrity, unlike cryovac which primarily prevents contamination by vacuum sealing but does not actively control microbial growth. The thermal regulation in sous vide maintains a stable microbiome barrier, reducing spoilage and enhancing food safety beyond the preservation methods offered by cryovac packaging.

Sous vide vs cryovac for ingredient preparation Infographic

cookingdiff.com

cookingdiff.com