Sous vide cooking ensures precise temperature control by vacuum-sealing meat and immersing it in a water bath heated to an exact target, resulting in evenly cooked, tender, and flavorful outcomes. Low-temperature water baths without vacuum sealing often lead to inconsistent heating and moisture loss, reducing meat quality and texture. The airtight environment of sous vide preserves juices and enhances flavor absorption compared to traditional low-temperature water baths.

Table of Comparison

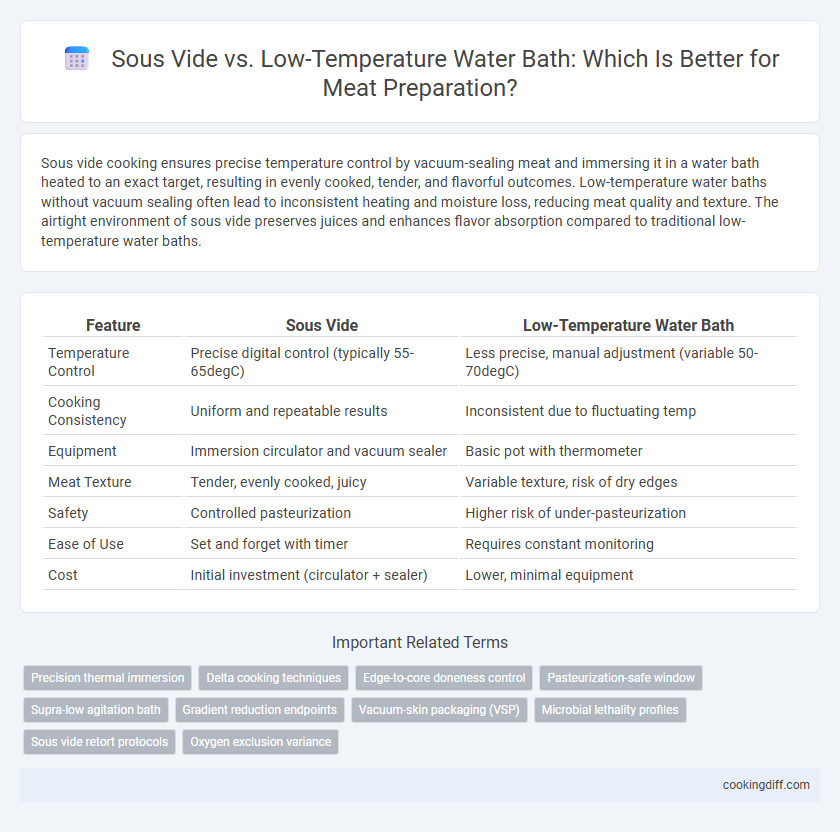

| Feature | Sous Vide | Low-Temperature Water Bath |

|---|---|---|

| Temperature Control | Precise digital control (typically 55-65degC) | Less precise, manual adjustment (variable 50-70degC) |

| Cooking Consistency | Uniform and repeatable results | Inconsistent due to fluctuating temp |

| Equipment | Immersion circulator and vacuum sealer | Basic pot with thermometer |

| Meat Texture | Tender, evenly cooked, juicy | Variable texture, risk of dry edges |

| Safety | Controlled pasteurization | Higher risk of under-pasteurization |

| Ease of Use | Set and forget with timer | Requires constant monitoring |

| Cost | Initial investment (circulator + sealer) | Lower, minimal equipment |

Introduction: Comparing Sous Vide and Low-Temperature Water Bath Techniques

Sous vide and low-temperature water bath techniques both involve precisely controlled cooking temperatures to achieve tender and evenly cooked meat. Sous vide utilizes vacuum-sealed bags and immersion circulators, ensuring consistent heat distribution throughout the cooking process.

Low-temperature water baths may lack the vacuum sealing but can still maintain stable temperatures using thermostatic devices. Both methods enhance meat texture and flavor by preventing overcooking and moisture loss.

How Sous Vide Works: Precision Cooking Explained

Sous vide cooking involves sealing meat in a vacuum bag and submerging it in a precisely controlled water bath, maintaining temperatures usually between 130degF and 160degF. This method ensures even cooking from edge to edge without overcooking or drying out the meat.

Unlike traditional low-temperature water baths, sous vide uses a circulator to maintain exact temperature control with minimal fluctuation, optimizing texture and flavor. The vacuum sealing prevents air exposure, which locks in moisture and enhances the infusion of marinades or seasonings. This precision cooking technique results in consistently tender, juicy meat unmatched by simpler low-temp methods.

Understanding Low-Temperature Water Bath Methods

Low-temperature water bath methods gently cook meat by submerging it in water maintained at precise temperatures, ensuring consistent doneness and moisture retention. Sous vide is a specific type of low-temperature water bath cooking that uses vacuum-sealed bags to enhance flavor infusion and prevent oxidation.

- Temperature Control - Sous vide machines maintain exact temperatures within 0.1degC, while traditional low-temperature water baths may fluctuate, affecting cooking results.

- Vacuum Sealing - Sous vide uses vacuum-sealed bags to lock in juices and flavors, whereas low-temperature water baths without sealing might result in some flavor loss.

- Cooking Precision - Sous vide offers repeatable and precise cooking outcomes, while conventional low-temperature water baths rely more on monitoring and manual adjustments.

Equipment Differences: Sous Vide vs Water Bath

Sous vide equipment typically includes precision immersion circulators that maintain exact temperature control within a water bath, ensuring consistent cooking results. In contrast, traditional low-temperature water baths often rely on manual temperature adjustments without digital regulation, leading to less precise heat management.

Sous vide devices feature vacuum-sealed bags and airtight containers to enhance flavor infusion and moisture retention during cooking. Low-temperature water baths generally utilize open containers or basic pots without airtight seals, which may result in variable cooking environments and moisture loss.

Temperature Control and Consistency in Meat Preparation

| Temperature Control | Sous vide offers precise digital temperature regulation maintained within +-0.1degC, ensuring meat reaches exact desired doneness without overcooking. Low-temperature water baths typically lack such accuracy, leading to temperature fluctuations that can affect the final meat texture. Accurate temperature control directly influences enzymatic activity and collagen breakdown, optimizing tenderness. |

| Consistency in Meat Preparation | Sous vide cooking provides uniform heat distribution throughout the vacuum-sealed meat, producing consistent results batch after batch. In contrast, traditional low-temperature water baths may have uneven heat zones causing variability in cooking doneness and moisture retention. Consistent temperature and environment promote repeatable perfect texture and juiciness in sous vide-cooked meats. |

Flavor and Texture: Results from Both Methods

Sous vide cooking offers precise temperature control that enhances meat flavor retention and produces a tender, evenly cooked texture by sealing in juices. Low-temperature water baths also improve tenderness and moisture compared to traditional methods but lack the consistent temperature accuracy, leading to slight variability in texture. Both techniques elevate flavor intensity and juiciness over conventional cooking, with sous vide delivering more reliable and repeatable results.

Food Safety Considerations for Each Technique

Sous vide cooking utilizes precise temperature control to ensure meat reaches safe internal temperatures over extended periods, effectively eliminating harmful pathogens. Low-temperature water baths may pose a higher risk if temperature regulation is inconsistent, potentially allowing bacterial growth during the cooking process.

- Consistent Temperature Maintenance - Sous vide machines maintain steady temperatures, reducing the risk of undercooking and bacterial contamination.

- Pathogen Elimination Time - Sous vide cooking times are scientifically calibrated to kill pathogens at lower temperatures compared to traditional methods.

- Risks of Fluctuating Temperatures - Low-temperature water baths without precision control can allow unsafe temperature zones that promote bacterial proliferation.

Properly calibrated sous vide equipment ensures optimal food safety when preparing meats compared to unregulated low-temperature water baths.

Cooking Times: Efficiency and Practicality Compared

Sous vide cooking offers precise temperature control, resulting in consistent cooking times that tenderize meat evenly without overcooking. Low-temperature water bath methods may vary in temperature stability, leading to less predictable cooking durations and potential texture inconsistencies. Sous vide devices typically provide efficient heating and circulation, enhancing practicality for both home cooks and professional chefs aiming for exact cooking results.

Cost and Accessibility of Tools and Ingredients

How do the costs and accessibility of tools and ingredients compare between sous vide and low-temperature water bath methods for meat preparation? Sous vide requires specialized equipment such as immersion circulators, which can be an initial investment but offers precise temperature control for consistent results. In contrast, low-temperature water baths utilize more common kitchen items like stovetop pots and thermometers, making it a more budget-friendly option with easier ingredient access.

Related Important Terms

Precision thermal immersion

Sous vide cooking ensures precise thermal immersion by maintaining consistent water temperatures typically between 130degF to 160degF, allowing uniform cooking and optimal texture control for meat. Low-temperature water baths may lack the exact temperature regulation of sous vide devices, potentially resulting in uneven doneness and less predictable meat quality.

Delta cooking techniques

Sous vide and low-temperature water bath techniques both rely on precise temperature control, but sous vide offers superior consistency by using vacuum-sealed bags that enhance heat transfer and flavor retention. Delta cooking techniques optimize thermal gradients, minimizing temperature fluctuations and ensuring even doneness throughout the meat.

Edge-to-core doneness control

Sous vide cooking ensures precise edge-to-core doneness control by maintaining a consistent water temperature that evenly penetrates meat, preventing overcooking at the edges while properly cooking the center. In contrast, traditional low-temperature water baths often lack the precise temperature regulation necessary to achieve uniform doneness, resulting in uneven textures and less consistent results.

Pasteurization-safe window

Sous vide cooking offers a precise pasteurization-safe window by maintaining consistent temperatures between 130degF and 140degF, effectively eliminating harmful bacteria while preserving meat's texture and flavor. In contrast, traditional low-temperature water baths may fluctuate, risking insufficient pasteurization and uneven cooking results.

Supra-low agitation bath

Sous vide cooking employs precise temperature control to achieve consistent doneness in meat, whereas low-temperature water baths may lack uniform heat distribution, affecting texture and safety. Supra-low agitation baths enhance sous vide results by promoting even heat circulation and minimizing temperature gradients, resulting in superior tenderness and juiciness.

Gradient reduction endpoints

Sous vide cooking ensures precise temperature control, minimizing gradient reduction endpoints by maintaining uniform heat distribution throughout the meat, resulting in consistent doneness and enhanced texture. In contrast, low-temperature water baths often create temperature gradients that lead to uneven cooking and less predictable meat quality.

Vacuum-skin packaging (VSP)

Vacuum-skin packaging (VSP) creates a tight seal around meat, minimizing air pockets and enhancing heat transfer during sous vide cooking compared to traditional low-temperature water baths. This method improves flavor retention, reduces oxidation, and ensures consistent texture by maintaining precise temperature control throughout the cooking process.

Microbial lethality profiles

Sous vide and low-temperature water bath methods differ significantly in microbial lethality profiles, with sous vide offering precise temperature control that ensures uniform pathogen reduction and safety in meat preparation. The controlled environment of sous vide maintains consistent temperatures typically between 55degC and 65degC, effectively targeting harmful microbes like Salmonella and Listeria while preserving meat texture and juiciness.

Sous vide retort protocols

Sous vide retort protocols utilize precisely controlled temperature and pressure environments, offering consistent and safe meat preparation compared to traditional low-temperature water baths that may lack rigorous monitoring systems. This method enhances flavor retention, texture uniformity, and microbial safety by combining vacuum sealing with retort sterilization parameters optimized for various meat cuts.

Sous vide vs low-temperature water bath for meat preparation. Infographic

cookingdiff.com

cookingdiff.com