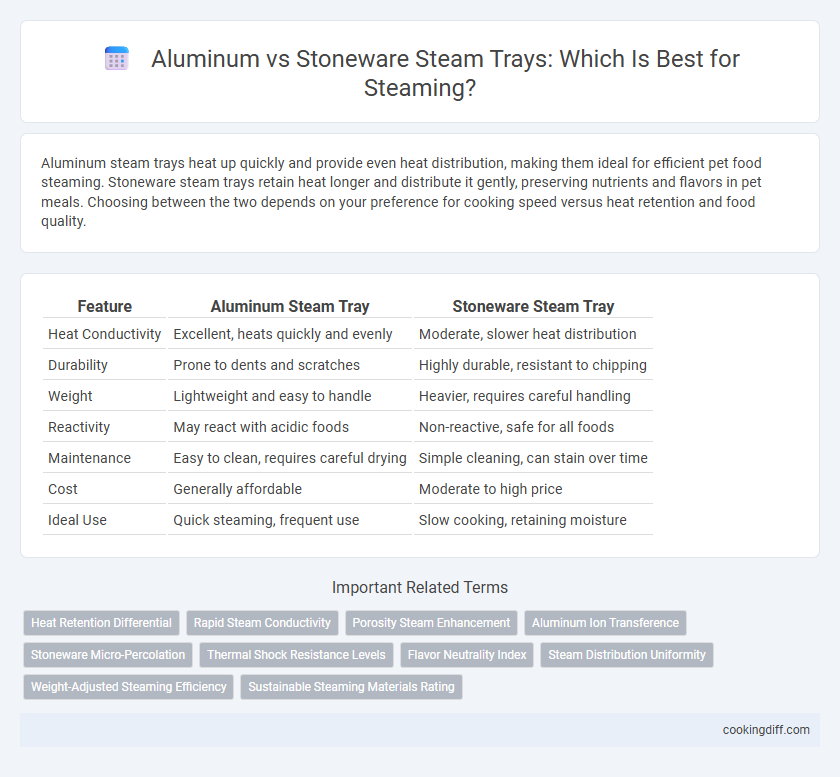

Aluminum steam trays heat up quickly and provide even heat distribution, making them ideal for efficient pet food steaming. Stoneware steam trays retain heat longer and distribute it gently, preserving nutrients and flavors in pet meals. Choosing between the two depends on your preference for cooking speed versus heat retention and food quality.

Table of Comparison

| Feature | Aluminum Steam Tray | Stoneware Steam Tray |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Moderate, slower heat distribution |

| Durability | Prone to dents and scratches | Highly durable, resistant to chipping |

| Weight | Lightweight and easy to handle | Heavier, requires careful handling |

| Reactivity | May react with acidic foods | Non-reactive, safe for all foods |

| Maintenance | Easy to clean, requires careful drying | Simple cleaning, can stain over time |

| Cost | Generally affordable | Moderate to high price |

| Ideal Use | Quick steaming, frequent use | Slow cooking, retaining moisture |

Introduction: Aluminum vs Stoneware Steam Trays

Aluminum steam trays offer excellent heat conductivity, ensuring faster and more even steaming compared to other materials. Stoneware steam trays provide superior heat retention and a non-reactive surface, making them ideal for delicate foods that require gentle, consistent steam. Choosing between aluminum and stoneware depends on cooking speed preferences and the type of food being steamed.

Heat Distribution: Comparing Aluminum and Stoneware

| Material | Heat Distribution |

|---|---|

| Aluminum Steam Tray | Aluminum offers excellent thermal conductivity, allowing for rapid and even heat distribution which ensures consistent steaming results and reduces cooking time. |

| Stoneware Steam Tray | Stoneware heats more slowly and retains heat longer, providing steady, gentle steaming but may result in less uniform distribution compared to aluminum. |

Steaming Efficiency and Performance

Aluminum steam trays offer superior steaming efficiency due to their excellent thermal conductivity, allowing heat to distribute quickly and evenly across the surface. This rapid heat transfer results in faster cooking times and more consistent steaming performance.

Stoneware steam trays retain heat longer but heat up more slowly, which can lead to uneven steaming and extended cooking durations. Their low thermal conductivity makes them less responsive to temperature changes, affecting overall steaming efficiency.

Durability and Longevity of Each Material

Aluminum steam trays offer exceptional durability due to their lightweight yet sturdy metal composition, resisting dents and corrosion over time. This material provides excellent heat conduction, which helps maintain consistent steaming temperatures for prolonged use.

Stoneware steam trays boast long-lasting resilience through their thick, non-porous ceramic structure, resistant to chipping and thermal shock. Their natural material also retains heat effectively, ensuring steady steaming performance while maintaining structural integrity after repeated use.

Ease of Cleaning and Maintenance

Aluminum steam trays are generally easier to clean due to their smooth, non-porous surface that resists food sticking. Stoneware steam trays require more careful maintenance to prevent staining and cracking from thermal shock.

- Aluminum steam tray cleaning - Wipes clean quickly with mild detergent and avoids residue buildup.

- Stoneware steam tray maintenance - Needs gentle scrubbing and avoidance of harsh chemicals to preserve glaze.

- Durability in cleaning - Aluminum withstands frequent washing without damage, while stoneware is more fragile.

Choosing aluminum steam trays simplifies routine cleaning and reduces long-term maintenance efforts.

Health and Safety Considerations

Aluminum steam trays are lightweight and conduct heat efficiently but may leach trace amounts of aluminum into food, raising health concerns with prolonged exposure. Stoneware steam trays are non-reactive and provide a safer, toxin-free steaming surface, minimizing risks associated with metal leaching.

Stoneware steam trays are less likely to warp or degrade under high heat, ensuring consistent safety and durability over time. Aluminum trays require careful handling to avoid scratches that can harbor bacteria or cause metal contamination. Selecting stoneware steam trays enhances long-term health safety and reduces chemical exposure during steaming.

Flavor Impact: Does the Material Affect Taste?

Aluminum steam trays conduct heat quickly, which can sometimes impart a slight metallic taste to delicate foods. Stoneware steam trays, however, provide a more neutral flavor profile by evenly distributing heat without affecting the food's natural taste.

- Aluminum Conductivity - Aluminum's high thermal conductivity speeds up cooking but may introduce a faint metallic flavor.

- Stoneware Neutrality - Stoneware's porous surface absorbs and retains heat evenly, preserving the authentic taste of steamed food.

- Flavor Integrity - Stoneware steam trays are preferred for flavor-sensitive dishes due to their minimal impact on taste compared to aluminum.

Versatility and Compatibility with Steamers

Which steam tray offers greater versatility and compatibility with various steamers? Aluminum steam trays excel in heat conduction and are highly compatible with most standard steamers, making them ideal for quick, even steaming. Stoneware steam trays provide versatile cooking options with their heat retention but may not fit all steamer models due to their rigid design and weight.

Cost and Availability of Steam Trays

Aluminum steam trays are generally more affordable and widely available in kitchen supply stores due to their lightweight and durable nature. Stoneware steam trays tend to be more expensive and less common, often found in specialty or high-end culinary shops. Cost efficiency and accessibility make aluminum trays a popular choice for everyday steaming needs.

Related Important Terms

Heat Retention Differential

Aluminum steam trays heat up quickly but lose heat rapidly, resulting in less consistent steaming temperatures, whereas stoneware steam trays retain heat much longer, providing steady and even heat distribution that enhances cooking performance. The superior thermal mass of stoneware ensures prolonged heat retention, reducing temperature fluctuations during the steaming process.

Rapid Steam Conductivity

Aluminum steam trays offer superior rapid steam conductivity due to their high thermal conductivity rate of approximately 205 W/mK, enabling faster and more even heat distribution during steaming compared to stoneware trays, which have lower thermal conductivity around 1.5 W/mK. This efficient heat transfer in aluminum trays ensures quicker cooking times and consistent steaming results, while stoneware steam trays provide slower heat absorption and retention, making them less optimal for rapid steaming applications.

Porosity Steam Enhancement

Aluminum steam trays exhibit low porosity, providing rapid heat conduction but limited steam absorption, which can result in uneven moisture distribution during steaming. Stoneware steam trays, with their higher porosity, enhance steam retention and circulation, promoting consistent moisture absorption and more uniform cooking results.

Aluminum Ion Transference

Aluminum steam trays facilitate heat conduction but may release aluminum ions into food during steaming, raising concerns about potential health risks. Stoneware steam trays, composed of inert ceramic material, prevent aluminum ion transfer and provide a safer option for cooking without compromising flavor retention.

Stoneware Micro-Percolation

Stoneware steam trays utilize micro-percolation technology that allows steam to evenly circulate through tiny pores, enhancing heat retention and moisture distribution for superior cooking results compared to aluminum trays. Aluminum steam trays, while lightweight and conductive, lack this porous structure, often resulting in less consistent steaming and potential hot spots.

Thermal Shock Resistance Levels

Aluminum steam trays offer excellent thermal conductivity but have moderate thermal shock resistance, making them susceptible to warping or cracking when exposed to sudden temperature changes. Stoneware steam trays possess superior thermal shock resistance, maintaining structural integrity and heat retention even under rapid temperature fluctuations, ideal for consistent and safe steaming.

Flavor Neutrality Index

Aluminum steam trays typically exhibit a higher Flavor Neutrality Index, ensuring that foods retain their original taste without metallic interference during steaming. Stoneware steam trays offer excellent heat retention but may impart subtle earthy notes, resulting in a slightly lower Flavor Neutrality Index compared to aluminum.

Steam Distribution Uniformity

Aluminum steam trays offer superior steam distribution uniformity due to their excellent thermal conductivity, ensuring even heating and consistent cooking results. Stoneware steam trays tend to heat unevenly, causing hot spots that can lead to inconsistent steaming and variable food texture.

Weight-Adjusted Steaming Efficiency

Aluminum steam trays offer lightweight properties that enhance heat conduction and reduce cooking time, improving weight-adjusted steaming efficiency compared to heavier stoneware steam trays. Stoneware trays retain heat longer but require more energy to raise temperature, making aluminum the preferred choice for faster, energy-efficient steaming.

Aluminum steam tray vs stoneware steam tray for steaming. Infographic

cookingdiff.com

cookingdiff.com