Steaming dumplings using a traditional bamboo steamer preserves their delicate texture and enhances the natural flavor, offering a moist and tender bite. In contrast, using a dim sum cabinet steamer provides consistent, efficient steaming with temperature control, ideal for larger batches and commercial settings. Choosing between the two depends on whether you prioritize authentic texture or convenient, scalable preparation.

Table of Comparison

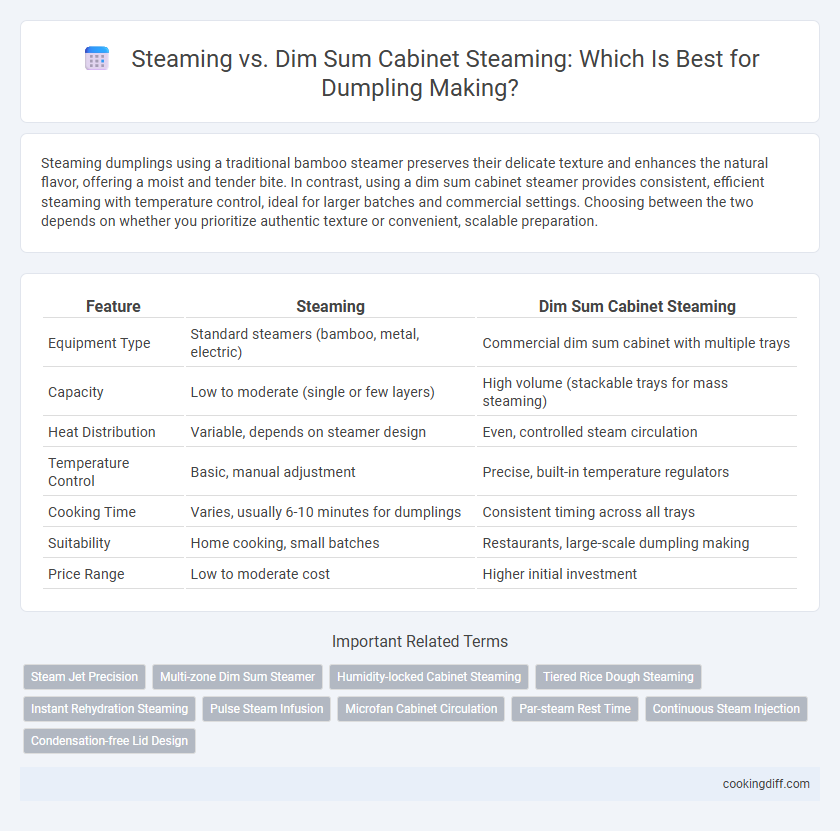

| Feature | Steaming | Dim Sum Cabinet Steaming |

|---|---|---|

| Equipment Type | Standard steamers (bamboo, metal, electric) | Commercial dim sum cabinet with multiple trays |

| Capacity | Low to moderate (single or few layers) | High volume (stackable trays for mass steaming) |

| Heat Distribution | Variable, depends on steamer design | Even, controlled steam circulation |

| Temperature Control | Basic, manual adjustment | Precise, built-in temperature regulators |

| Cooking Time | Varies, usually 6-10 minutes for dumplings | Consistent timing across all trays |

| Suitability | Home cooking, small batches | Restaurants, large-scale dumpling making |

| Price Range | Low to moderate cost | Higher initial investment |

Introduction: Steaming in Dumpling Preparation

What are the key differences between steaming and dim sum cabinet steaming in dumpling preparation? Steaming uses direct steam heat to cook dumplings evenly and retain moisture, ensuring a tender texture. Dim sum cabinet steaming provides a controlled environment with consistent humidity and temperature, ideal for large batches and maintaining dumpling freshness.

What is Dim Sum Cabinet Steaming?

Dim Sum Cabinet Steaming is a specialized steaming method designed for efficiently cooking large batches of dim sum and dumplings. This technique uses a multi-tiered cabinet that evenly distributes steam, ensuring consistent heat and moisture for perfectly steamed dumplings. Unlike traditional steaming, the cabinet setup allows for faster cooking times and maintains product quality in commercial kitchens.

Traditional Steaming Methods Explained

Traditional steaming methods for dumpling making involve using bamboo steamers or metal steamers placed over boiling water, ensuring gentle and even heat distribution that preserves the delicate texture and flavor of the dumplings. This technique allows steam to circulate freely, cooking the dumplings consistently without direct contact with water.

Dim Sum cabinet steaming utilizes a controlled environment with adjustable temperature and humidity settings, ideal for large-scale or commercial production of dumplings. Compared to traditional steaming, it offers precise steam control and efficiency but may lack the subtle texture nuances achieved through conventional methods.

Equipment Comparison: Standard Steamers vs Dim Sum Cabinets

Standard steamers offer direct heat and efficient steam flow, making them ideal for smaller, home-based dumpling preparation. Dim Sum cabinets provide precise humidity control and large capacity, catering to commercial-scale production with consistent results.

- Temperature Control - Standard steamers typically have manual temperature settings, whereas Dim Sum cabinets allow precise, programmable control for uniform cooking.

- Capacity - Standard steamers accommodate limited batches, while Dim Sum cabinets can hold multiple trays, optimizing volume for busy kitchens.

- Moisture Retention - Dim Sum cabinets maintain stable humidity levels, ensuring dumplings stay moist, compared to the variable conditions of standard steamers.

Choosing between these steamers depends on the scale of dumpling production and desired cooking consistency.

Temperature and Moisture Control Differences

Steaming dumplings in a traditional steamer allows precise temperature control, usually maintaining around 100degC with consistent moist heat. Dim sum cabinet steaming employs enclosed steam chambers that ensure uniform moisture distribution but may fluctuate in temperature due to varying load levels.

- Temperature consistency - Traditional steamers maintain steady heat, preventing overcooking and preserving dumpling texture.

- Moisture control - Dim sum cabinets provide saturated steam that keeps dumplings moist but can risk sogginess if overexposed.

- Steam circulation - Cabinet steamers use forced steam circulation to evenly cook multiple trays simultaneously.

Steaming Efficiency: Batch Size and Cooking Time

Steaming efficiency varies significantly between traditional steaming methods and dim sum cabinet steaming, especially regarding batch size and cooking time. Dim sum cabinets allow for larger batch sizes with even heat distribution, reducing overall cooking time compared to conventional steamers. Optimizing batch size in cabinet steaming ensures consistent dumpling quality while maximizing throughput in commercial kitchens.

Impact on Dumpling Texture and Flavor

Steaming dumplings using a traditional steaming method evenly distributes heat and moisture, resulting in a tender and slightly chewy texture that enhances the delicate flavor of the filling. This method preserves the juiciness inside the dumplings, maintaining a balanced contrast between the wrapper and the savory interior.

Dim sum cabinet steaming offers a more controlled and consistent environment, which can lead to uniform texture across batches but may slightly reduce the complex caramelization effects on the dumpling skin. While it keeps dumplings warm for extended periods, the extended exposure can sometimes cause the wrappers to become softer and less crisp, subtly affecting the overall flavor profile.

Practical Considerations in Home and Commercial Kitchens

Steaming dumplings in a Dim Sum Cabinet offers precise temperature control and efficient batch cooking, making it ideal for commercial kitchens. Home kitchens benefit more from traditional steaming methods due to their simplicity and space efficiency.

- Dim Sum Cabinet Steaming - Provides consistent heat distribution suitable for large volume cooking in commercial settings.

- Traditional Steaming - Requires less space and is more cost-effective for home cooking applications.

- Energy Consumption - Dim Sum Cabinets generally consume more energy but reduce cooking time compared to home steamers.

Maintenance and Cleaning Requirements

| Steaming | Requires regular descaling to prevent mineral buildup, and thorough drying to avoid mold growth; simple design allows for easy disassembly and cleaning. |

| Dim Sum Cabinet Steaming | Needs frequent wiping of interior surfaces to remove food residue and grease, plus periodic deep cleaning to maintain hygiene standards; complex structure may require professional maintenance. |

Related Important Terms

Steam Jet Precision

Steam Jet Precision enhances dumpling quality by delivering consistent, targeted steam that ensures even cooking and optimal texture. Unlike traditional dim sum cabinet steaming, Steam Jet systems minimize moisture loss and prevent sogginess, resulting in perfectly steamed dumplings with superior taste and appearance.

Multi-zone Dim Sum Steamer

Multi-zone dim sum steamers offer precise temperature and humidity control across different compartments, ensuring consistent dumpling texture and flavor unlike traditional steaming methods. These steamers optimize energy use and steaming efficiency, making them ideal for high-volume dim sum production compared to standard steaming cabinets.

Humidity-locked Cabinet Steaming

Humidity-locked cabinet steaming maintains optimal moisture levels by enclosing steam within a sealed environment, ensuring consistent heat distribution and preventing dumplings from drying out. This method contrasts with traditional steaming by offering precise humidity control, resulting in dumplings with a softer texture and enhanced flavor retention.

Tiered Rice Dough Steaming

Tiered rice dough steaming offers uniform heat distribution and moisture retention, resulting in perfectly tender dumplings compared to traditional dim sum cabinet steaming, which may cause uneven cooking due to compartmentalized trays. This method enhances texture and flavor by allowing steam to circulate freely around each layer, making it ideal for delicate rice dough dumplings.

Instant Rehydration Steaming

Instant rehydration steaming rapidly restores moisture in dumplings, preserving delicate textures and flavors better than traditional dim sum cabinet steaming, which maintains constant heat but often leads to uneven steaming and moisture loss. This method optimizes cooking time and enhances quality by delivering efficient steam penetration, crucial for consistently soft and juicy dumplings.

Pulse Steam Infusion

Pulse Steam Infusion maximizes moisture retention and even heat distribution in dumpling making, outperforming traditional Dim Sum Cabinet Steaming by reducing cooking time and preserving texture. This advanced steaming technology injects intermittent bursts of steam, ensuring consistent quality and enhanced flavor in each dumpling batch.

Microfan Cabinet Circulation

Microfan Cabinet Circulation in steaming ensures even heat distribution and consistent moisture levels, which is essential for perfectly cooked dumplings. This technology outperforms traditional Dim Sum Cabinet Steaming by maintaining precise temperature control and reducing condensation, resulting in tender, flavorful dumplings with optimal texture.

Par-steam Rest Time

Par-steam rest time significantly affects dumpling texture and moisture retention, with steaming allowing a longer rest period for dough relaxation and filling stabilization. Dim sum cabinet steaming offers precise temperature control but typically has shorter par-steam rest times, which can reduce dough elasticity and result in less tender dumplings.

Continuous Steam Injection

Continuous steam injection ensures even heat distribution and consistent moisture levels, preventing dumplings from drying out during cooking. Unlike traditional dim sum cabinet steaming, this method enhances texture and flavor by maintaining a stable steaming environment ideal for delicate dumpling wrappers.

Steaming vs Dim Sum Cabinet Steaming for dumpling making. Infographic

cookingdiff.com

cookingdiff.com