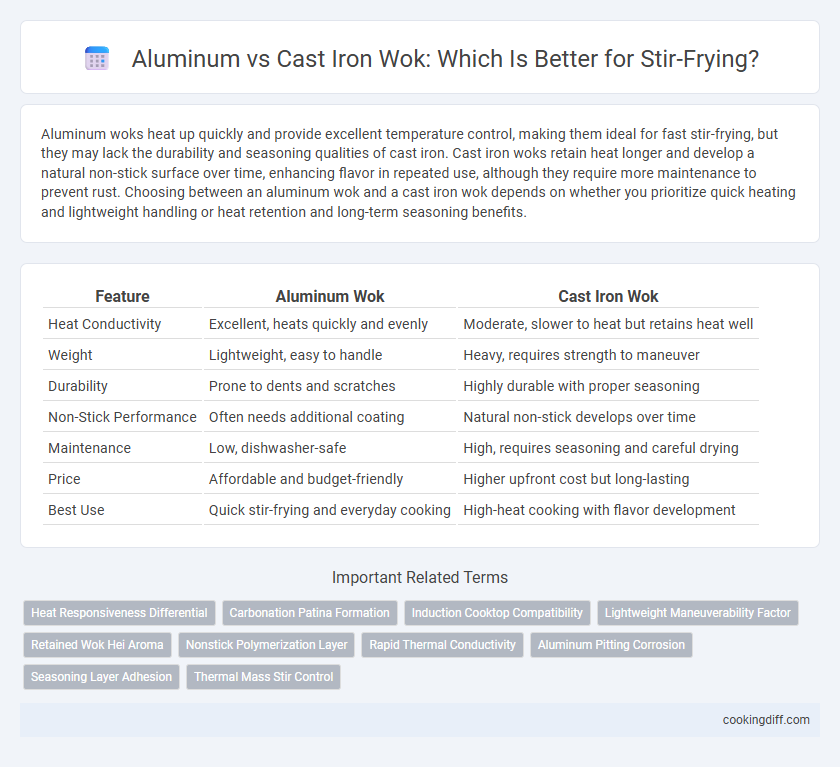

Aluminum woks heat up quickly and provide excellent temperature control, making them ideal for fast stir-frying, but they may lack the durability and seasoning qualities of cast iron. Cast iron woks retain heat longer and develop a natural non-stick surface over time, enhancing flavor in repeated use, although they require more maintenance to prevent rust. Choosing between an aluminum wok and a cast iron wok depends on whether you prioritize quick heating and lightweight handling or heat retention and long-term seasoning benefits.

Table of Comparison

| Feature | Aluminum Wok | Cast Iron Wok |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Moderate, slower to heat but retains heat well |

| Weight | Lightweight, easy to handle | Heavy, requires strength to maneuver |

| Durability | Prone to dents and scratches | Highly durable with proper seasoning |

| Non-Stick Performance | Often needs additional coating | Natural non-stick develops over time |

| Maintenance | Low, dishwasher-safe | High, requires seasoning and careful drying |

| Price | Affordable and budget-friendly | Higher upfront cost but long-lasting |

| Best Use | Quick stir-frying and everyday cooking | High-heat cooking with flavor development |

Material Composition: Aluminum vs Cast Iron Woks

Aluminum woks are lightweight and offer excellent heat conductivity, allowing for quick and even heating during stir-frying. Cast iron woks retain heat longer and provide superior heat distribution, which is ideal for high-heat cooking and developing complex flavors. The choice between aluminum and cast iron woks depends on whether you prioritize fast heating or heat retention and durability.

Heat Conductivity and Distribution

Aluminum woks offer superior heat conductivity, allowing for rapid and even heating essential for stir-frying. Cast iron woks provide excellent heat retention and more uniform heat distribution, though they take longer to heat up.

- Aluminum's thermal conductivity - It heats up quickly, ensuring food cooks evenly at high temperatures.

- Cast iron heat retention - It maintains consistent heat, ideal for prolonged cooking sessions.

- Heat distribution difference - Aluminum spreads heat faster, while cast iron evenly distributes heat once hot.

Choosing between aluminum and cast iron woks depends on the balance between quick heating and sustained heat retention for optimal stir-frying performance.

Preheating and Cooking Speed Comparison

| Wok Type | Preheating Time | Cooking Speed |

|---|---|---|

| Aluminum Wok | Typically 1-2 minutes due to excellent heat conductivity | Faster cooking as heat distributes quickly and evenly |

| Cast Iron Wok | Requires 5-7 minutes to reach optimal cooking temperature | Slower initial cooking speed but retains heat longer for consistent stir-fry |

Weight and Ease of Handling

Aluminum woks are significantly lighter than cast iron woks, making them easier to handle during quick stir-frying processes. Their lightweight nature allows for better maneuverability and less wrist strain, ideal for fast, high-heat cooking techniques.

Cast iron woks, although heavier, provide excellent heat retention but can be cumbersome to lift and toss ingredients rapidly. The added weight requires more strength and control, which may slow down the stir-fry technique for some cooks.

Seasoning and Maintenance Requirements

Aluminum woks heat quickly but require frequent seasoning to prevent sticking and oxidation, demanding consistent maintenance for optimal performance. Cast iron woks develop a natural non-stick patina over time through seasoning, reducing the need for frequent reapplication and enhancing flavor with ongoing use. Maintaining cast iron involves careful drying and oiling after each use to prevent rust, while aluminum woks demand gentler cleaning to preserve their seasoning layer.

Durability and Longevity

Aluminum woks offer lightweight handling and rapid heat conduction but tend to wear out faster due to their softer metal composition, making them less durable for long-term use. Frequent exposure to high heat during stir-frying can cause aluminum woks to warp or discolor over time.

Cast iron woks are renowned for their exceptional durability and longevity, with the material's density allowing for even heat distribution that improves with seasoning. Properly maintained cast iron woks can last decades, resisting warping and developing a natural non-stick surface ideal for repeated stir-frying.

Nonstick Properties for Stir-Frying

Aluminum woks typically have superior nonstick properties due to their smooth surface and faster heating capabilities, which reduce food sticking during stir-frying. Cast iron woks, while excellent for heat retention, often require more seasoning to maintain a nonstick surface, impacting initial cooking performance.

Seasoned cast iron woks develop a natural nonstick coating over time, enhancing flavor but demanding regular maintenance to prevent rust. Aluminum woks offer consistent nonstick performance with less upkeep, making them ideal for quick, high-heat stir-frying. However, cast iron's heavier weight and uneven seasoning can sometimes cause food to stick if not properly cared for.

Flavor Development and Wok Hei Potential

Which wok material enhances flavor development and maximizes wok hei potential for stir-frying? Cast iron woks retain heat exceptionally well, creating consistent high temperatures ideal for caramelizing ingredients and developing rich, smoky flavors central to authentic stir-fry dishes. Aluminum woks heat quickly but struggle to maintain high heat, limiting the depth of flavor and the characteristic "breath of the wok" or wok hei essential for traditional stir-frying.

Compatibility with Stovetops and Heat Sources

Aluminum woks heat up quickly and are compatible with most gas and electric stovetops, but they may warp under high heat. Cast iron woks excel in retaining heat and work well on gas, electric, and induction stovetops, though they require proper seasoning to prevent rust.

- Aluminum wok compatibility - Suitable for gas and electric stovetops but not ideal for induction due to lack of magnetic properties.

- Cast iron wok compatibility - Works efficiently with gas, electric, and induction cooktops, offering versatile stovetop options.

- Heat retention differences - Cast iron retains heat longer, providing consistent cooking temperatures compared to aluminum.

Related Important Terms

Heat Responsiveness Differential

Aluminum woks heat up quickly and offer superior heat responsiveness, allowing precise temperature control essential for stir-frying delicate ingredients. Cast iron woks retain heat longer but respond slower to temperature changes, making them better suited for cooking that benefits from even, sustained heat.

Carbonation Patina Formation

Cast iron woks develop a natural carbonation patina over time, enhancing non-stick properties and flavor depth during stir-frying. Aluminum woks lack this ability, resulting in less seasoning buildup and a different cooking surface behavior.

Induction Cooktop Compatibility

Cast iron woks offer superior heat retention and are fully compatible with induction cooktops due to their magnetic properties, ensuring even cooking and efficient energy use. Aluminum woks generally require a magnetic base or induction interface disk to function effectively on induction cooktops, as pure aluminum lacks the magnetic properties needed for induction heating.

Lightweight Maneuverability Factor

Aluminum woks offer superior lightweight maneuverability, enabling quick, precise tossing essential for stir-frying techniques that require high heat and rapid cooking. In contrast, cast iron woks are heavier, which can hinder fast movement but provide excellent heat retention and even cooking.

Retained Wok Hei Aroma

Cast iron woks retain heat longer, enhancing the wok hei aroma essential for authentic stir-frying, while aluminum woks heat quickly but lose heat rapidly, resulting in less pronounced wok hei flavors. The superior heat retention of cast iron woks allows for consistent high temperatures that produce the characteristic smoky, charred aroma critical to traditional stir-fried dishes.

Nonstick Polymerization Layer

Aluminum woks heat up quickly and evenly but often require a nonstick polymerization layer to prevent food from sticking during stir-frying. Cast iron woks develop a natural nonstick seasoning through repeated use, creating a durable polymerized layer that enhances flavor and improves cooking performance over time.

Rapid Thermal Conductivity

Aluminum woks offer superior thermal conductivity, reaching high temperatures rapidly and ensuring even heat distribution essential for quick stir-frying. Cast iron woks, while slower to heat, retain heat longer and provide stable, consistent cooking temperatures ideal for prolonged stir-fry sessions.

Aluminum Pitting Corrosion

Aluminum woks offer excellent heat conductivity for stir-frying but are prone to pitting corrosion, especially when exposed to acidic ingredients or prolonged moisture. Cast iron woks, though heavier and slower to heat, resist pitting corrosion and provide superior durability and heat retention for high-temperature cooking.

Seasoning Layer Adhesion

Aluminum woks heat quickly but often struggle with seasoning layer adhesion due to their smooth, non-porous surface, leading to less effective non-stick properties. Cast iron woks develop a robust, durable seasoning layer over time, enhancing flavor retention and providing superior non-stick performance essential for traditional stir-frying techniques.

Aluminum wok vs Cast iron wok for stir-frying. Infographic

cookingdiff.com

cookingdiff.com