Aluminum woks heat up quickly and distribute heat evenly, making them efficient for stir-frying while being lightweight and affordable. Copper woks offer superior heat conductivity and precise temperature control, ideal for delicate stir-fry techniques, but they require more careful maintenance to prevent tarnishing. Choosing between aluminum and copper woks depends on balancing ease of use, heat responsiveness, and maintenance preferences.

Table of Comparison

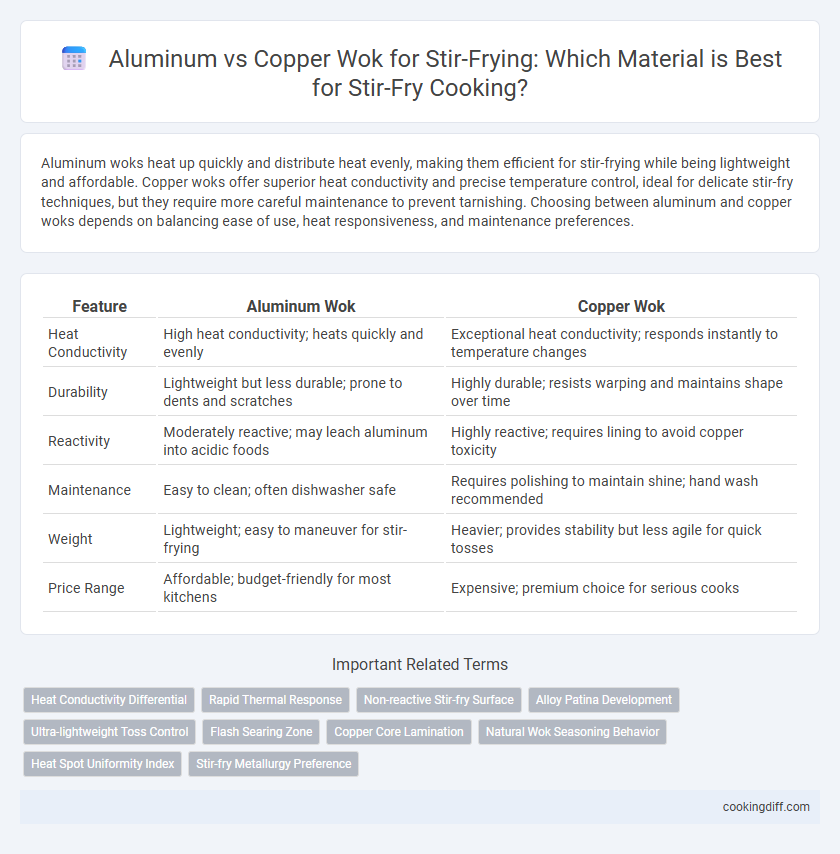

| Feature | Aluminum Wok | Copper Wok |

|---|---|---|

| Heat Conductivity | High heat conductivity; heats quickly and evenly | Exceptional heat conductivity; responds instantly to temperature changes |

| Durability | Lightweight but less durable; prone to dents and scratches | Highly durable; resists warping and maintains shape over time |

| Reactivity | Moderately reactive; may leach aluminum into acidic foods | Highly reactive; requires lining to avoid copper toxicity |

| Maintenance | Easy to clean; often dishwasher safe | Requires polishing to maintain shine; hand wash recommended |

| Weight | Lightweight; easy to maneuver for stir-frying | Heavier; provides stability but less agile for quick tosses |

| Price Range | Affordable; budget-friendly for most kitchens | Expensive; premium choice for serious cooks |

Introduction: Choosing the Right Wok for Stir-Frying

| Material | Heat Conductivity | Durability | Best Use |

|---|---|---|---|

| Aluminum Wok | Excellent heat conduction, heats quickly and evenly | Lightweight but prone to warping and scratching | Ideal for quick, high-heat stir-frying and everyday cooking |

| Copper Wok | Superior heat responsiveness and precise temperature control | Highly durable yet requires regular polishing to prevent tarnish | Best for professional-level stir-frying demanding precise heat adjustments |

Aluminum Wok: Overview and Key Features

Aluminum woks offer excellent heat conductivity, allowing for quick and even cooking essential for stir-frying. Lightweight and affordable, aluminum woks heat up rapidly and respond well to temperature changes, making them ideal for high-heat cooking techniques. However, they may react with acidic ingredients unless coated or anodized, which enhances durability and non-stick properties.

Copper Wok: Overview and Key Features

What makes a copper wok ideal for stir-frying? Copper woks offer exceptional heat conductivity, allowing for rapid temperature adjustments and even cooking. Their natural antimicrobial properties and durability make them a preferred choice for professional chefs seeking precise control and longevity in the kitchen.

Heat Conductivity Comparison: Aluminum vs Copper

Aluminum woks offer excellent heat conductivity, allowing them to heat up quickly and distribute heat evenly across the surface, which is crucial for consistent stir-frying. Their lightweight nature makes them easy to handle during high-heat cooking techniques.

Copper woks provide superior thermal conductivity compared to aluminum, enabling faster temperature adjustments and precise heat control essential for delicate stir-frying tasks. However, copper woks often require more maintenance to prevent discoloration and maintain their conductivity performance.

Weight, Handling, and Maneuverability

Aluminum woks are significantly lighter than copper woks, enhancing ease of handling during quick stir-frying motions. Copper woks, while heavier, offer superior heat control but can be cumbersome for prolonged tossing and flipping.

- Weight - Aluminum woks weigh less, reducing arm fatigue during extended cooking sessions.

- Handling - Copper woks demand a steadier grip due to their weight, affecting agility.

- Maneuverability - Aluminum woks are easier to maneuver, ideal for fast, high-heat stir-frying techniques.

Choosing between aluminum and copper woks depends on prioritizing either lightweight convenience or enhanced heat responsiveness for optimal stir-frying performance.

Durability and Maintenance Differences

Aluminum woks are lightweight and resistant to rust but can warp easily under high heat, impacting their durability during intense stir-frying. Copper woks offer superior heat conductivity and durability, maintaining shape longer but require frequent polishing to prevent tarnishing.

Maintenance for aluminum woks is relatively simple; they are dishwasher safe and easy to clean, though they may discolor with time. Copper woks demand more care, including regular polishing and gentle hand washing to preserve their appearance and performance.

Cooking Performance in Stir-Frying

Aluminum woks heat up quickly and distribute heat evenly, making them suitable for fast stir-frying at high temperatures. Copper woks offer superior heat conductivity and precise temperature control, which is ideal for delicate stir-frying tasks requiring quick temperature adjustments.

- Heat Conductivity - Copper woks conduct heat better than aluminum, allowing faster and more responsive temperature changes.

- Durability - Aluminum woks are lighter but prone to warping under high heat, whereas copper woks maintain shape and performance over time.

- Flavor Development - Both materials support high heat cooking, but copper's even heat distribution aids in more consistent browning and flavor development.

Price Considerations: Which Offers Better Value?

Aluminum woks are generally more affordable, making them a popular choice for budget-conscious cooks seeking efficient heat conduction during stir-frying. Copper woks, while significantly pricier, provide superior thermal responsiveness and even heat distribution, enhancing cooking precision for experienced chefs. Evaluating the balance between cost and performance, aluminum woks offer better value for everyday use, whereas copper woks justify their expense in professional or specialized culinary settings.

Health and Safety Aspects of Each Material

Aluminum woks are lightweight and provide excellent heat conduction but may leach metals into food if the surface is scratched or worn. Copper woks offer superior temperature control and quick heating but require proper lining to prevent copper exposure, which can be toxic if ingested in large amounts.

- Aluminum Reactivity - Uncoated aluminum woks can release aluminum ions when cooking acidic foods, raising health concerns over long-term exposure.

- Copper Toxicity Risk - Copper woks must be lined, commonly with stainless steel or tin, to avoid copper leaching that may cause gastrointestinal issues.

- Maintenance Requirements - Both materials require careful maintenance to preserve their non-toxic cooking surfaces and prevent potential contamination.

Related Important Terms

Heat Conductivity Differential

Aluminum woks offer superior heat conductivity with a thermal conductivity of approximately 237 W/m*K, enabling rapid and even heat distribution essential for precise stir-frying techniques. In contrast, copper woks provide an even higher thermal conductivity around 401 W/m*K, allowing for faster temperature adjustments and better heat responsiveness, though they typically require more maintenance to prevent oxidation.

Rapid Thermal Response

Aluminum woks offer rapid thermal response and even heat distribution, making them ideal for quick stir-frying techniques that require precise temperature control. Copper woks provide superior heat conductivity but may heat unevenly and respond slower to temperature changes compared to lightweight aluminum options.

Non-reactive Stir-fry Surface

Aluminum woks offer excellent heat conductivity but may react with acidic ingredients, potentially altering flavors and causing surface corrosion. Copper woks provide superior heat control yet often require a non-reactive lining like stainless steel to prevent food from reacting with the metal during stir-frying.

Alloy Patina Development

Aluminum woks develop a natural patina from oxidation that improves non-stick properties and enhances heat distribution over time during stir-frying. Copper woks form a unique alloy patina that offers superior thermal conductivity and rapid heat response, ideal for precise temperature control in high-heat cooking.

Ultra-lightweight Toss Control

Aluminum woks offer ultra-lightweight toss control, enhancing maneuverability and rapid heat adjustments essential for precise stir-frying techniques. Copper woks, while excellent in heat conductivity, tend to be heavier, potentially reducing the ease of tossing and quick handling during high-speed cooking.

Flash Searing Zone

Aluminum woks excel in rapid heat conduction and maintaining a consistent Flash Searing Zone, ideal for high-temperature stir-frying that locks in flavors quickly. Copper woks offer superior temperature control and faster heat response, but their smaller Flash Searing Zone may require more attention to avoid uneven searing during stir-frying.

Copper Core Lamination

Copper core lamination in woks combines rapid heat conductivity with even heat distribution, enhancing stir-frying performance by minimizing hot spots and allowing precise temperature control. Compared to aluminum woks, copper core laminated woks offer superior thermal responsiveness, durability, and consistent cooking results essential for high-heat, quick cooking techniques like stir-frying.

Natural Wok Seasoning Behavior

Aluminum woks heat quickly but may struggle to develop a durable natural seasoning layer compared to copper woks, which promote better seasoning buildup due to their superior heat conductivity and even temperature distribution. Natural wok seasoning enhances non-stick properties and flavor retention, making copper woks preferable for achieving optimal stir-frying performance over time.

Heat Spot Uniformity Index

Copper woks exhibit superior Heat Spot Uniformity Index compared to aluminum woks, ensuring even heat distribution essential for consistent stir-frying results. Aluminum woks tend to develop uneven hot spots that can cause food to cook irregularly, impacting texture and flavor.

Aluminum wok vs Copper wok for stir-frying. Infographic

cookingdiff.com

cookingdiff.com