Gas burners provide immediate, adjustable heat and a visible flame, allowing precise control essential for traditional stir-frying techniques that require rapid temperature changes. Induction wok burners offer faster heating and energy efficiency with consistent heat distribution but may lack the responsiveness and high-heat intensity favored by experienced stir-fry chefs. Choosing between gas and induction depends on balancing control and efficiency based on cooking style preferences.

Table of Comparison

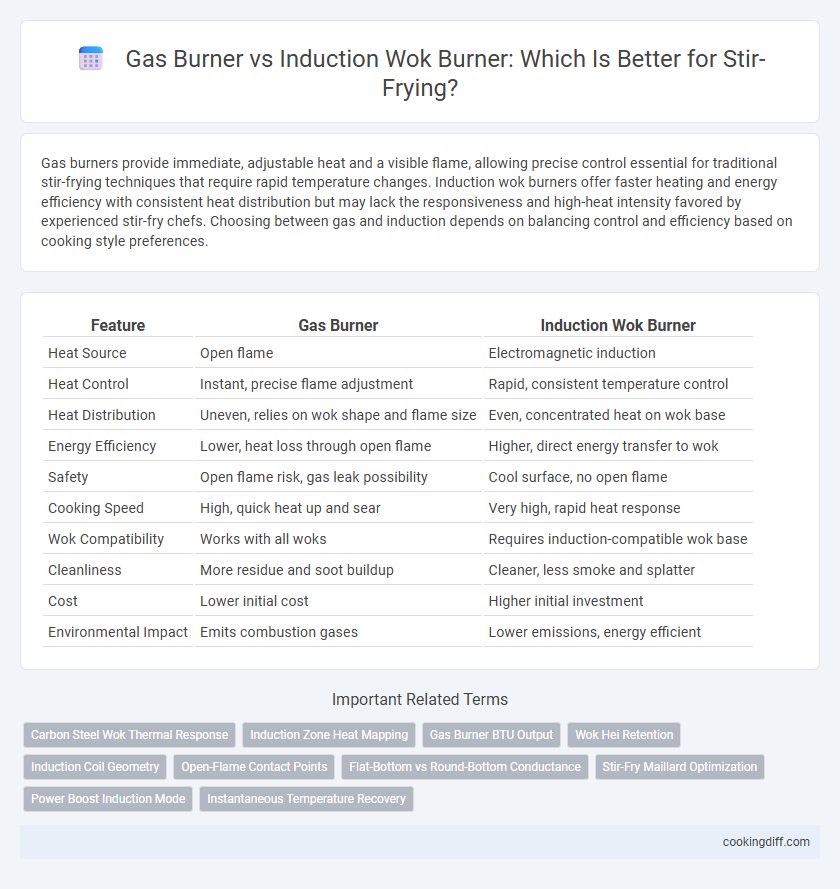

| Feature | Gas Burner | Induction Wok Burner |

|---|---|---|

| Heat Source | Open flame | Electromagnetic induction |

| Heat Control | Instant, precise flame adjustment | Rapid, consistent temperature control |

| Heat Distribution | Uneven, relies on wok shape and flame size | Even, concentrated heat on wok base |

| Energy Efficiency | Lower, heat loss through open flame | Higher, direct energy transfer to wok |

| Safety | Open flame risk, gas leak possibility | Cool surface, no open flame |

| Cooking Speed | High, quick heat up and sear | Very high, rapid heat response |

| Wok Compatibility | Works with all woks | Requires induction-compatible wok base |

| Cleanliness | More residue and soot buildup | Cleaner, less smoke and splatter |

| Cost | Lower initial cost | Higher initial investment |

| Environmental Impact | Emits combustion gases | Lower emissions, energy efficient |

Introduction: Gas Burner vs Induction Wok Burner for Stir-Frying

| Gas burners provide high, immediate heat essential for traditional stir-frying, allowing precise temperature control and a smoky flavor from open flames. Induction wok burners offer rapid, even heating with improved energy efficiency and safety features, but may require compatible cookware and can lack the high heat intensity of gas. Selecting between gas and induction depends on prioritizing authentic cooking techniques versus modern convenience and energy savings. |

Heat Control and Responsiveness

Gas burners provide immediate and precise heat control essential for traditional stir-frying techniques, allowing chefs to quickly adjust flame intensity. Induction wok burners offer rapid temperature changes and consistent heat distribution but may lack the tactile responsiveness of an open flame.

- Gas burner heat variability - Enables fine-tuned flame adjustments crucial for achieving the wok hei flavor.

- Induction burner temperature precision - Maintains stable and even heat essential for consistent stir-fry cooking.

- Responsiveness comparison - Gas burners respond instantly to knob changes, while induction burners adjust heat more gradually due to electronic controls.

Wok Hei: Achieving Authentic Flavors

Gas burners provide an open flame that reaches high temperatures quickly, essential for developing the smoky aroma known as "wok hei" in traditional stir-frying. Induction wok burners offer precise temperature control but often lack the intense heat and flame distribution needed to achieve authentic wok hei flavor.

Wok hei, or the "breath of the wok," results from rapid searing at very high heat, creating complex, charred flavors that gas burners excel at producing. Induction burners heat through electromagnetic fields, delivering even heat but cannot replicate the direct flame's effect on the wok's surface. For chefs seeking genuine stir-fry taste, gas wok burners remain the preferred choice, blending speed and flavor complexity unattainable with most induction units.

Temperature Consistency and Distribution

Which burner provides better temperature consistency and distribution for stir-frying, gas or induction wok burners? Gas burners typically offer superior temperature control with instant flame adjustments, allowing for precise heat management necessary for authentic stir-frying. Induction wok burners deliver even heat distribution and rapid temperature recovery, but may lack the nuanced flame control that expert chefs require for optimal stir-fry results.

Energy Efficiency and Environmental Impact

Induction wok burners convert electricity directly into heat with approximately 80-90% energy efficiency, reducing overall energy consumption during stir-frying. Gas burners typically operate at 40-55% efficiency, releasing more heat and combustion emissions into the environment.

- Higher Energy Transfer Efficiency - Induction burners deliver heat faster and with less energy loss compared to gas, optimizing cooking time and reducing utility usage.

- Lower Carbon Emissions - Induction cooktops produce no combustion gases on-site, significantly minimizing indoor air pollution and carbon footprint relative to gas burners.

- Sustainability of Energy Source - The environmental impact of induction cooking correlates with the electricity generation mix, favoring renewable sources over fossil fuels used for gas burners.

Safety Considerations in the Kitchen

Gas burners provide visible flames that allow immediate response to flare-ups, enhancing safety during stir-frying. Induction wok burners offer precise temperature control with no open flame, reducing risks of fire and burns. Both options require proper ventilation and caution to prevent accidents in the kitchen environment.

Equipment Compatibility and Material Choices

Gas burners offer broad compatibility with various wok materials like carbon steel and cast iron, ensuring even heating crucial for stir-frying. Induction wok burners require magnetic cookware such as stainless steel or specially designed induction-compatible woks for efficient heating. Choosing the right burner depends on wok material to maximize heat control and cooking performance during stir-fry preparation.

Cleaning and Maintenance Comparison

Gas burners tend to accumulate grease and food particles, requiring regular cleaning of grates and drip pans to maintain optimal performance. Their open flame design makes it easier to spot and remove spills, but can be more labor-intensive to clean thoroughly.

Induction wok burners feature smooth, flat surfaces that resist buildup and simplify maintenance with just a quick wipe. The sealed cooktop prevents food and liquids from entering the burner, reducing the risk of clogging and making cleaning faster and more hygienic.

Cost Analysis: Upfront and Operating Expenses

Gas burners typically have lower upfront costs compared to induction wok burners, making them more accessible for budget-conscious cooks. Operating expenses for gas rely on consistent propane or natural gas supply, which can fluctuate based on regional fuel prices.

Induction wok burners incur higher initial investment due to advanced technology and specialized cookware requirements. However, they offer energy efficiency that reduces long-term electricity costs and improves precise temperature control during stir-frying.

Related Important Terms

Carbon Steel Wok Thermal Response

Gas burners provide intense, direct flame that quickly heats carbon steel woks, enabling rapid thermal response essential for traditional stir-frying techniques. Induction wok burners offer precise temperature control and consistent heat distribution but may have slower thermal response times compared to gas, affecting the wok's ability to reach high searing temperatures instantly.

Induction Zone Heat Mapping

Induction wok burners provide precise heat control through induction zone heat mapping, ensuring even and rapid temperature distribution that prevents hot spots and promotes consistent stir-frying results. Unlike gas burners, induction technology targets the wok's base directly, enhancing energy efficiency and allowing chefs to fine-tune heat intensity for delicate cooking techniques.

Gas Burner BTU Output

Gas burners for stir-frying typically offer BTU outputs ranging from 15,000 to over 25,000, providing intense, direct heat essential for achieving the high temperatures required for proper wok cooking. This powerful BTU output enables rapid temperature changes and optimal wok hei, making gas burners preferred over induction wok burners, which generally have lower heat intensity despite efficient energy use.

Wok Hei Retention

Gas burners provide intense, direct flame heat that enhances Wok Hei retention by allowing quick temperature changes and achieving the high heat levels essential for authentic stir-frying flavor. Induction wok burners offer precise temperature control but may struggle to replicate the rapid heat fluctuations and smoky essence characteristic of traditional Wok Hei.

Induction Coil Geometry

Induction wok burners with specialized coil geometry provide precise, uniform heat distribution essential for high-heat stir-frying, outperforming traditional gas burners by minimizing hotspots and enhancing energy efficiency. The tailored coil design ensures rapid heat response and consistent temperature control, optimizing wok performance and preserving the texture and flavor of stir-fried ingredients.

Open-Flame Contact Points

Gas burners provide direct open-flame contact points that deliver intense, concentrated heat essential for traditional stir-frying techniques, enabling rapid searing and wok hei flavor development. Induction wok burners lack open flames, offering precise temperature control but often fail to replicate the high-heat, direct flame contact required for authentic stir-fry caramelization and charring.

Flat-Bottom vs Round-Bottom Conductance

Gas burners provide direct flame contact ideal for round-bottom woks, ensuring even heat distribution by enveloping the curved surface, while induction wok burners require flat-bottom woks for optimal magnetic conductance and efficient heat transfer. The flat-bottom design on induction burners maximizes contact with the coil, delivering rapid and precise temperature control critical for stir-frying techniques.

Stir-Fry Maillard Optimization

Gas burners provide intense, immediate heat ideal for achieving the Maillard reaction in stir-frying, creating superior browning and flavor development due to open flame contact. Induction wok burners offer precise temperature control and rapid heat adjustments, but may lack the direct flame exposure that maximizes Maillard browning during high-heat stir-fry cooking.

Power Boost Induction Mode

Gas burners provide instant, high heat with precise flame control essential for traditional stir-frying, while induction wok burners with Power Boost Induction Mode deliver rapid, consistent heating through electromagnetic energy, allowing faster temperature recovery and energy efficiency. Power Boost Induction Mode enhances stir-frying performance by reaching peak temperatures quickly, reducing cooking time and maintaining even heat distribution crucial for authentic wok hei flavor.

Gas burner vs Induction wok burner for stir-frying. Infographic

cookingdiff.com

cookingdiff.com