Stir-frying automation relies on precise temperature control and rapid ingredient movement to replicate traditional cooking techniques, while wok tossing robotics emphasize dynamic wrist-like motions to mimic skilled chef tossing. Stir-frying focuses on consistent heat application and even cooking, whereas wok tossing robots prioritize ingredient flipping and aeration to enhance flavor and texture. Integrating both approaches can optimize automated Asian cuisine preparation by balancing thermal precision with mechanical dexterity.

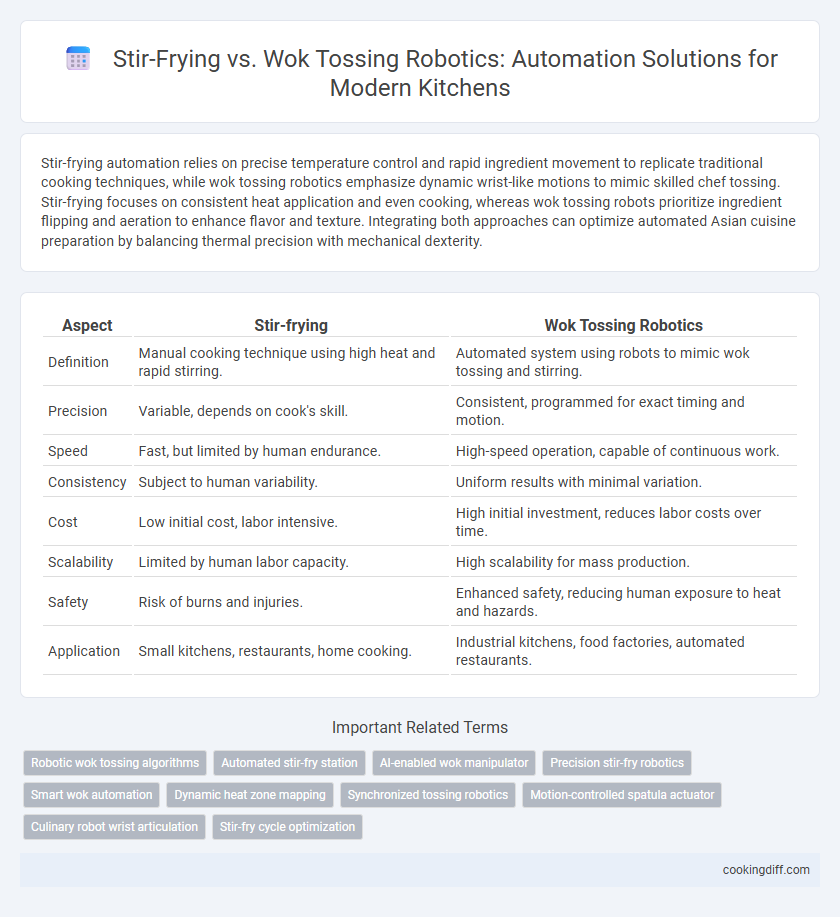

Table of Comparison

| Aspect | Stir-frying | Wok Tossing Robotics |

|---|---|---|

| Definition | Manual cooking technique using high heat and rapid stirring. | Automated system using robots to mimic wok tossing and stirring. |

| Precision | Variable, depends on cook's skill. | Consistent, programmed for exact timing and motion. |

| Speed | Fast, but limited by human endurance. | High-speed operation, capable of continuous work. |

| Consistency | Subject to human variability. | Uniform results with minimal variation. |

| Cost | Low initial cost, labor intensive. | High initial investment, reduces labor costs over time. |

| Scalability | Limited by human labor capacity. | High scalability for mass production. |

| Safety | Risk of burns and injuries. | Enhanced safety, reducing human exposure to heat and hazards. |

| Application | Small kitchens, restaurants, home cooking. | Industrial kitchens, food factories, automated restaurants. |

Introduction to Stir-Frying and Wok Tossing Automation

Stir-frying is a high-heat cooking technique that requires rapid, continuous movement of ingredients in a hot pan, typically a wok, to achieve even cooking and retain texture. Wok tossing involves skillful flipping and stirring motions to mix ingredients thoroughly while preventing burning.

Automation in stir-frying leverages robotics with precise control of temperature and motion to replicate human dexterity and speed in food preparation. Wok tossing robotics focus on dynamic flipping mechanisms and real-time ingredient monitoring to ensure consistent quality and efficiency.

Evolution of Wok Cooking: From Human Hands to Robotics

Stir-frying traditionally demands precise, rapid wrist movements to achieve perfect heat distribution and flavor balance, a skill developed over centuries. Recent advancements in robotics have transformed wok tossing by utilizing AI and sensor technology to replicate human dexterity and timing in automated cooking processes.

- Human Expertise in Stir-frying - Skilled chefs control heat and ingredient motion intuitively to maintain texture and taste.

- Robotic Wok Tossing - Machines use programmed algorithms and sensors to simulate human movements with consistent precision.

- Evolution Impact - Automation enhances efficiency and scalability in commercial kitchens while preserving traditional cooking quality.

Key Differences: Traditional Stir-Frying vs Robotic Wok Tossing

Stir-frying involves manual control of heat and ingredient movement for precise cooking, while robotic wok tossing automates these actions with programmed consistency and speed.

- Control Precision - Traditional stir-frying relies on the chef's skill to adjust tossing intensity and timing, whereas robotics use sensors and algorithms to optimize the process.

- Consistency - Manual stir-frying can vary with each cook, but robotic systems deliver uniform results across batches.

- Speed and Efficiency - Robotic wok tossing can operate continuously with minimal fatigue, outperforming human cooks in high-volume environments.

Robotic wok tossing enhances automation by replicating stir-frying techniques with improved repeatability and labor efficiency.

Precision and Consistency: The Robotic Advantage

Robotic stir-frying systems deliver exceptional precision, maintaining consistent temperature and cooking times to ensure even heat distribution and optimal flavor retention. Unlike manual wok tossing, robots can replicate exact movements repeatedly, reducing human error and enhancing product quality.

Automation in stir-frying enables uniform ingredient mixing and precise control over stir-fry speeds, which is difficult to achieve with traditional wok tossing methods. These robots improve consistency, increase efficiency, and minimize waste, making them ideal for high-volume food production environments.

Flavor and Texture: Can Automation Match Human Skill?

Stir-frying relies on precise heat control and quick, agile movements to develop complex flavors and maintain the ideal texture of ingredients. Automation through wok tossing robotics attempts to replicate this dynamic by programming consistent motion patterns and temperature regulation.

Human chefs excel at adjusting techniques in real-time based on ingredient response, enhancing both flavor depth and textural contrast. Robotics can achieve repeatability and speed, but often lack the intuitive sensory feedback needed to mimic nuanced seasoning and doneness levels. Advances in AI and sensor integration are narrowing this gap, yet fully matching human skill in flavor and texture optimization remains a significant challenge.

Speed, Efficiency, and Scalability in Automated Kitchens

Stir-frying robotics excel in speed by maintaining consistent high heat and rapid tossing motions that mimic expert chefs, significantly reducing cooking time. Wok tossing robots enhance efficiency through precise ingredient handling and uniform cooking, minimizing waste and energy consumption. Scalability in automated kitchens is achieved by integrating these technologies with IoT systems, enabling simultaneous multi-dish preparation and real-time process optimization.

Cleaning, Maintenance, and Operational Costs

Stir-frying robotics generally require less frequent cleaning due to precise temperature control and contained cooking environments, reducing residue buildup. Wok tossing robotics demand more intensive maintenance and higher operational costs due to complex mechanical movements and open cooking surfaces.

- Cleaning Efficiency - Stir-frying robots feature sealed components that prevent splatter, making them easier to clean than wok tossing robots.

- Maintenance Complexity - Wok tossing robotics involve sophisticated arm movements that increase wear and necessitate regular mechanical servicing.

- Operational Costs - Stir-frying systems typically consume less energy and have fewer parts prone to breakdown, lowering long-term expenses.

Safety Concerns: Manual vs Automated Stir-Frying

How do safety concerns differ between manual stir-frying and automated wok tossing robotics? Manual stir-frying exposes chefs to high heat, hot oil splashes, and physical strain, increasing the risk of burns and repetitive motion injuries. Automated wok tossing robotics utilize sensors and precise movements to minimize human exposure to hazards, enhancing workplace safety and reducing accident rates in food processing environments.

Market Adoption: Restaurants and Industrial Applications

| Stir-frying robots gain rapid adoption in restaurants due to precision and consistent heat control, enhancing flavor and texture in high-volume kitchens. Wok tossing robotics see broader use in industrial food processing where scalable, high-throughput production lines require automated batch handling. Market trends indicate stir-frying automation dominates quick-serve and specialized Asian cuisine eateries, while wok tossing systems drive efficiency in frozen meal factories and mass food manufacturing. |

Related Important Terms

Robotic wok tossing algorithms

Robotic wok tossing algorithms optimize ingredient motion and heat distribution by precisely controlling the wok's tilt and rotation speed, ensuring even cooking and flavor development. These algorithms integrate real-time sensor data and AI-driven pattern recognition to mimic human stir-frying techniques, enhancing automation efficiency and food quality.

Automated stir-fry station

Automated stir-fry stations leverage precise temperature control and robotic arms to mimic traditional stir-frying techniques, ensuring even heat distribution and consistent ingredient mixing. Compared to wok tossing robotics, these stations offer enhanced scalability and integration with smart kitchen systems, optimizing efficiency and food quality in commercial kitchens.

AI-enabled wok manipulator

AI-enabled wok manipulators enhance stir-frying automation by precisely controlling heat distribution and ingredient movement, improving cooking consistency and efficiency compared to traditional wok tossing robotics. These systems leverage real-time sensory data and machine learning algorithms to mimic complex hand movements, optimizing flavor development and reducing manual labor in commercial kitchens.

Precision stir-fry robotics

Precision stir-fry robotics utilize advanced sensors and AI algorithms to control temperature, timing, and ingredient movement, ensuring consistent texture and flavor in automated stir-frying processes. Compared to traditional wok tossing robotics, these systems offer enhanced accuracy and repeatability, reducing human error and maximizing culinary quality in high-volume food production.

Smart wok automation

Smart wok automation leverages advanced robotics and AI sensors to optimize stir-frying by precisely controlling heat, timing, and ingredient tossing, ensuring consistent texture and flavor. Compared to traditional wok tossing robotics, smart wok systems enhance efficiency through real-time adjustments and adaptive cooking patterns, reducing human intervention and food waste in commercial kitchens.

Dynamic heat zone mapping

Dynamic heat zone mapping in stir-frying robotics enables precise temperature control across various sections of the wok, enhancing cooking consistency and preventing overheating. Compared to wok tossing automation, this approach optimizes energy efficiency and ingredient quality by adjusting heat distribution in real-time based on sensor data.

Synchronized tossing robotics

Synchronized tossing robotics in stir-frying automation enhance cooking precision and uniform heat distribution by coordinating wok movements with ingredient release, minimizing manual intervention and improving consistency. These advanced systems outperform traditional wok tossing robots by replicating human-like wrist flicks and timing, optimizing stir-fry texture and flavor in high-volume kitchen environments.

Motion-controlled spatula actuator

Motion-controlled spatula actuators in stir-frying robotics enable precise manipulation of ingredients through dynamic and varied wrist movements, closely mimicking human techniques for even cooking and optimal texture. Compared to wok tossing automation, these actuators provide enhanced control over ingredient agitation and flipping, reducing ingredient damage and improving consistency in automated culinary processes.

Culinary robot wrist articulation

Stir-frying demands precise wrist articulation to achieve rapid, multidirectional movement for even heat distribution and ingredient mixing, while wok tossing robotics require advanced robotic wrists capable of dynamic, fluid flipping motions to replicate traditional cooking techniques. Enhanced dexterity in culinary robot wrist articulation improves automation efficiency, maintaining food texture and flavor consistency essential for high-quality stir-fry dishes.

Stir-frying vs Wok tossing robotics for automation Infographic

cookingdiff.com

cookingdiff.com