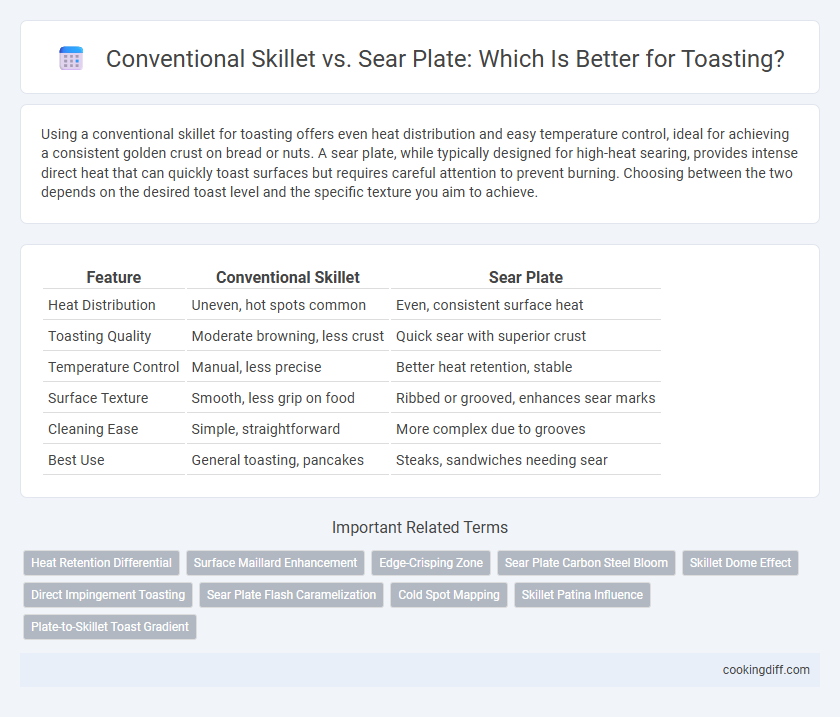

Using a conventional skillet for toasting offers even heat distribution and easy temperature control, ideal for achieving a consistent golden crust on bread or nuts. A sear plate, while typically designed for high-heat searing, provides intense direct heat that can quickly toast surfaces but requires careful attention to prevent burning. Choosing between the two depends on the desired toast level and the specific texture you aim to achieve.

Table of Comparison

| Feature | Conventional Skillet | Sear Plate |

|---|---|---|

| Heat Distribution | Uneven, hot spots common | Even, consistent surface heat |

| Toasting Quality | Moderate browning, less crust | Quick sear with superior crust |

| Temperature Control | Manual, less precise | Better heat retention, stable |

| Surface Texture | Smooth, less grip on food | Ribbed or grooved, enhances sear marks |

| Cleaning Ease | Simple, straightforward | More complex due to grooves |

| Best Use | General toasting, pancakes | Steaks, sandwiches needing sear |

Introduction to Toasting Methods: Skillet vs Sear Plate

Which toasting method delivers the best flavor: conventional skillet or sear plate? Conventional skillets offer even heat distribution, ideal for gentle toasting of bread and nuts. Sear plates provide intense direct heat, creating distinct char marks and a crispier texture on meats and vegetables.

What Is a Conventional Skillet?

A conventional skillet is a flat-bottomed pan typically made from materials like cast iron or stainless steel, designed for even heat distribution. It is versatile and commonly used for toasting bread or other foods over direct heat.

Conventional skillets provide consistent heat, allowing for controlled toasting without burning. Their smooth surface ensures even contact with the food, creating a uniform golden crust. Compared to sear plates, skillets offer more flexibility in temperature management for various toasting techniques.

Understanding the Sear Plate: Modern Toasting Explained

The sear plate offers a modern toasting method by providing consistent, high heat directly to the bread surface, ensuring an even golden crust with enhanced Maillard reactions. Unlike conventional skillets, sear plates maintain temperature stability, reducing the risk of uneven browning or burning during toasting.

Sear plates are typically made from cast iron or stainless steel with a grooved design, which facilitates fat drainage and airflow, improving toast texture and flavor. This advanced heat distribution outperforms standard skillets that often rely on indirect heat and can result in uneven toasting or longer cook times.

Heat Distribution: Skillet vs Sear Plate Performance

Conventional skillets provide even heat distribution ideal for consistent toasting across the entire surface, preventing hotspots. Sear plates, designed for high-heat contact, create intense heat zones that can enhance browning but may cause uneven toasting if not carefully managed.

- Conventional Skillet Heat Distribution - Offers uniform heat spread, ensuring all areas toast evenly.

- Sear Plate Heat Performance - Generates focused, intense heat that intensifies browning on direct contact points.

- Impact on Toasting - Skillets provide consistent results, while sear plates require attention to avoid scorching and uneven toasting.

Toasting Efficiency: Speed and Evenness Compared

| Toasting Method | Speed | Evenness |

|---|---|---|

| Conventional Skillet | Moderate heat transfer, requires frequent flipping for uniform browning | Uneven heat distribution often causes inconsistent toasting |

| Sear Plate | High heat retention enables faster toasting with less monitoring | Superior evenness due to uniform surface temperature across the plate |

Flavor and Texture: Which Method Wins?

Conventional skillets provide even heat distribution, allowing bread to develop a consistent golden crust with a balanced crunch and subtle caramelization. Sear plates, designed for high heat contact, create intense browning and a pronounced toasty flavor but may result in uneven texture due to hot spots. For optimal flavor and texture, skillets offer a more controlled toasting process, while sear plates excel in delivering bold, smoky notes with varied crispness.

Versatility in the Kitchen: Multi-Use Potential

Conventional skillets offer broad versatility for toasting a variety of foods, from bread to vegetables, due to their flat surface and even heat distribution. Their multi-use potential extends beyond toasting, making them essential for sauteing, frying, and simmering diverse ingredients.

Sear plates specialize in creating high-heat contact for intense browning and crisping, ideal for meats and certain toasts requiring a seared finish. While less versatile than skillets, sear plates excel in enhancing flavor through the Maillard reaction, adding a unique texture and depth to toasted dishes.

Cleaning and Maintenance: Skillet vs Sear Plate

Conventional skillets require regular seasoning and thorough scrubbing to prevent food residue buildup and maintain a non-stick surface. Sear plates often feature ridged patterns that trap crumbs, demanding specialized cleaning tools for effective maintenance.

- Skillet seasoning - Essential for creating a non-stick layer that enhances cleaning ease and prolongs cookware life.

- Sear plate ridges - These grooves collect food particles, necessitating detailed brushing to ensure hygiene.

- Material durability - Cast iron skillets withstand aggressive scrubbing, whereas some sear plates made from thinner metals require gentler care.

Choosing the right toasting surface influences cleaning frequency and method, impacting long-term cookware upkeep.

Cost and Accessibility Factors

Conventional skillets offer a cost-effective and widely accessible option for toasting, making them ideal for everyday use in most households. Sear plates, while often more expensive and less common, provide superior heat retention and even toasting, which might justify their higher cost for professional or frequent users. Budget-conscious consumers typically prefer conventional skillets due to their affordability and ease of availability in local stores.

Related Important Terms

Heat Retention Differential

Conventional skillets typically have lower heat retention compared to sear plates, resulting in less consistent toasting temperatures and longer cooking times. Sear plates, made from thicker and denser materials like cast iron, maintain high heat for extended periods, delivering evenly toasted surfaces with enhanced caramelization and flavor development.

Surface Maillard Enhancement

Conventional skillets provide consistent surface heat that allows for gradual Maillard reaction development, enhancing toast's flavor and texture through even browning. Sear plates, with their intense direct heat and ridged surfaces, create pronounced caramelization and distinct char marks that intensify flavor complexity but may risk uneven toasting.

Edge-Crisping Zone

Conventional skillets provide an even heat distribution ideal for general toasting but often lack a defined edge-crisping zone, resulting in less pronounced crispiness at the bread's perimeter. In contrast, sear plates concentrate heat along their ridged surface edges, creating a distinct edge-crisping zone that enhances texture and flavor in toasted bread slices.

Sear Plate Carbon Steel Bloom

Sear plate carbon steel bloom excels in toasting by providing intense, evenly distributed heat that enhances browning and flavor depth compared to a conventional skillet. Its dense material and robust thermal conductivity create optimal searing conditions, producing a crisp, caramelized crust while preserving interior moisture.

Skillet Dome Effect

The conventional skillet creates a dome effect that traps heat and moisture, enhancing even toasting by circulating hot air within the curved surface. This dome shape contrasts with the flat sear plate, which offers direct, high-heat contact but lacks the enclosed environment for consistent, uniform browning.

Direct Impingement Toasting

Direct impingement toasting delivers intense, focused heat directly onto the surface, making a sear plate more effective than a conventional skillet by providing consistent, high-temperature contact that ensures even browning and enhanced flavor development. The sear plate's design optimizes heat distribution and airflow, resulting in faster toasting with a crispier texture compared to the more diffuse heat of a conventional skillet.

Sear Plate Flash Caramelization

A sear plate enables flash caramelization by delivering intense, direct heat that rapidly browns the surface of the food, creating a rich, flavorful crust unmatched by the gentler, more uniform heat distribution of a conventional skillet. This high-temperature searing process enhances the Maillard reaction, intensifying toasted flavors and textures essential for gourmet culinary results.

Cold Spot Mapping

Cold spot mapping reveals that conventional skillets often have uneven heat distribution, leading to inconsistent toasting with some areas under-toasted. Sear plates, designed with enhanced thermal conductivity and surface contact, provide more uniform heat distribution, minimizing cold spots for even, consistent toasting results.

Skillet Patina Influence

A well-seasoned conventional skillet develops a patina that enhances flavor absorption and creates a natural non-stick surface, making it ideal for toasting bread evenly with subtle, complex flavors. In contrast, a sear plate lacks this seasoning layer, offering intense, direct heat that produces distinct char marks but less depth in flavor compared to the nuanced toasting achieved with a skillet's patina.

Conventional Skillet vs Sear Plate for toasting. Infographic

cookingdiff.com

cookingdiff.com