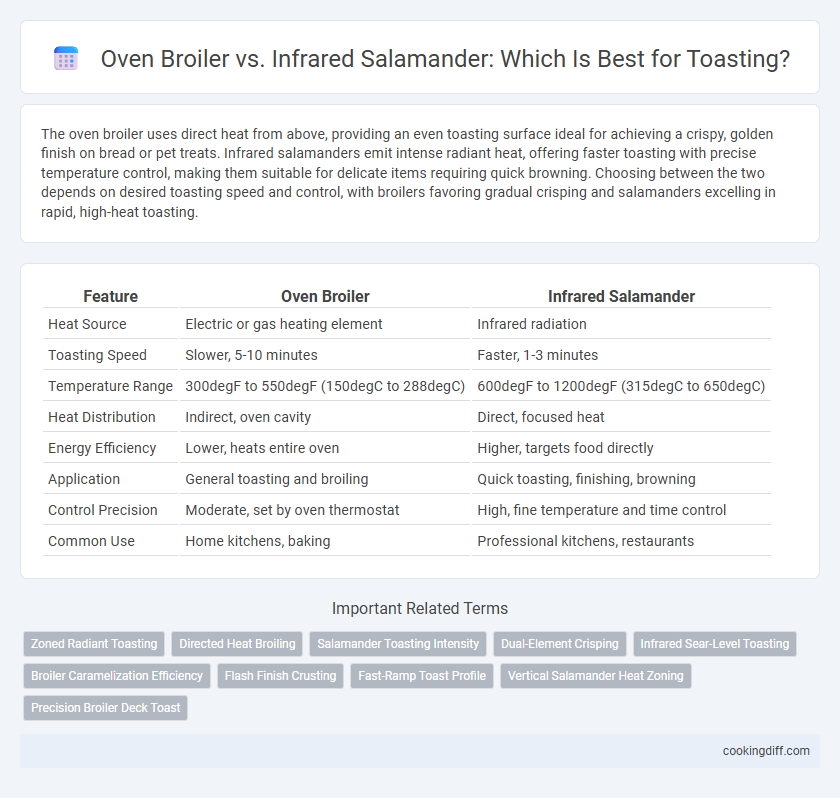

The oven broiler uses direct heat from above, providing an even toasting surface ideal for achieving a crispy, golden finish on bread or pet treats. Infrared salamanders emit intense radiant heat, offering faster toasting with precise temperature control, making them suitable for delicate items requiring quick browning. Choosing between the two depends on desired toasting speed and control, with broilers favoring gradual crisping and salamanders excelling in rapid, high-heat toasting.

Table of Comparison

| Feature | Oven Broiler | Infrared Salamander |

|---|---|---|

| Heat Source | Electric or gas heating element | Infrared radiation |

| Toasting Speed | Slower, 5-10 minutes | Faster, 1-3 minutes |

| Temperature Range | 300degF to 550degF (150degC to 288degC) | 600degF to 1200degF (315degC to 650degC) |

| Heat Distribution | Indirect, oven cavity | Direct, focused heat |

| Energy Efficiency | Lower, heats entire oven | Higher, targets food directly |

| Application | General toasting and broiling | Quick toasting, finishing, browning |

| Control Precision | Moderate, set by oven thermostat | High, fine temperature and time control |

| Common Use | Home kitchens, baking | Professional kitchens, restaurants |

Understanding Oven Broilers and Infrared Salamanders

Oven broilers use direct radiant heat from above to toast bread quickly and evenly, making them ideal for achieving a crispy crust. Infrared salamanders utilize infrared radiation to deliver intense, focused heat, allowing precise control over toasting without drying out the food.

- Heat Source Difference - Oven broilers emit heat from electric or gas elements, while infrared salamanders rely on specialized infrared lamps.

- Toasting Speed - Infrared salamanders typically toast faster due to their concentrated heat emission compared to the broader heat distribution in broilers.

- Precision Control - Infrared salamanders offer more accurate temperature control for delicate toasting tasks, whereas broilers provide more generalized heat.

How Each Appliance Works for Toasting

The oven broiler uses high-temperature radiant heat from above to toast bread evenly by directly exposing it to intense heat. Infrared salamanders employ infrared radiation that quickly browns and crisps the bread's surface through focused heat energy.

- Oven Broiler Heat Source - Utilizes gas or electric coils positioned atop the oven to emit radiant heat for toasting.

- Infrared Salamander Mechanism - Generates infrared waves that penetrate the bread's surface, ensuring rapid browning.

- Heat Distribution - Broilers provide broader heat coverage, while salamanders offer concentrated, precise toasting.

Each appliance delivers distinct heat methods suitable for different toasting preferences and speeds.

Heat Distribution: Broiler vs Salamander

Oven broilers use direct radiant heat from above, producing intense, uneven heat that can create hot spots, ideal for rapid toasting but requiring careful attention to prevent burning. Infrared salamanders emit infrared radiation that provides more uniform heat distribution, ensuring consistent toasting across the entire surface.

Broilers tend to concentrate heat more aggressively in certain areas, making them suitable for quick browning but less reliable for even cooking. Infrared salamanders maintain steady temperatures with minimal heat variation, enhancing texture and color uniformity in toasted foods.

Toasting Speed and Efficiency Comparison

Infrared salamanders offer faster toasting speeds due to their intense, focused heat, significantly reducing cooking time compared to oven broilers. While oven broilers provide even, consistent heat, they usually require more time and energy to achieve similar toasting results.

- Infrared Salamander Efficiency - Uses concentrated radiant heat for rapid surface toasting, optimizing speed and energy use.

- Oven Broiler Heating - Employs broader heat distribution, resulting in slower toasting but more uniform cooking.

- Energy Consumption - Infrared salamanders consume less energy due to shorter cooking cycles versus the longer cycles of oven broilers.

Toast Quality and Consistency

The oven broiler provides even heat distribution, resulting in consistent toasting but can sometimes lead to uneven browning due to varying rack positions. Infrared salamanders deliver intense, direct heat that ensures a crisp exterior and uniform toasting surface, enhancing overall toast quality. For professional kitchens prioritizing precision, infrared salamanders offer superior consistency and faster toasting times compared to traditional oven broilers.

Energy Consumption and Cost Implications

| Oven Broiler | Energy consumption ranges between 2,000 to 5,000 watts, leading to higher electricity bills during prolonged use. Initial setup costs tend to be lower, but operational expenses increase with frequent toasting due to inefficient heat transfer. |

| Infrared Salamander | Consumes approximately 1,200 to 2,000 watts, offering more efficient energy use through direct infrared heating. Although upfront costs are higher, reduced energy consumption results in lower long-term operating expenses and better cost-efficiency for commercial toasting applications. |

Versatility: Beyond Toasting Capabilities

Oven broilers provide versatile cooking options beyond toasting, enabling tasks such as broiling meats, melting cheese, and roasting vegetables with consistent heat distribution. Infrared salamanders excel at rapid, high-temperature toasting and finishing dishes but generally lack the broader cooking functions of oven broilers.

Broilers offer adjustable temperature settings suitable for various culinary techniques, supporting both delicate and intensive cooking processes. Infrared salamanders specialize in intense, direct heat ideal for caramelizing and crisping, making them less adaptable but highly effective for specific applications.

Space and Installation Considerations

Oven broilers typically require more kitchen space due to their larger size and built-in installation needs. Infrared salamanders are compact and designed for wall mounting, optimizing space in smaller kitchens.

Installing an oven broiler demands proper ventilation and clearance, which can complicate placement in tight areas. Infrared salamanders install easily with minimal clearance, making them flexible for various kitchen layouts. Their energy efficiency also reduces the need for extensive exhaust systems compared to traditional broilers.

Ease of Use and Maintenance

Oven broilers offer straightforward operation with standard temperature controls, making them easy to use for consistent toasting. Infrared salamanders provide rapid, intense heat, but require careful monitoring to avoid burning, which can complicate use for novices. Maintenance of oven broilers is simpler, as they typically have removable racks and accessible heating elements, whereas infrared salamanders demand regular cleaning of their quartz or metal infrared elements to ensure optimal performance.

Related Important Terms

Zoned Radiant Toasting

Oven broilers provide zoned radiant toasting by using upper heating elements to deliver direct heat, ideal for even browning and crisping of bread or toppings. Infrared salamanders offer more precise, intense zoned radiant heat focused on smaller areas, allowing faster, controlled toasting and caramelization in professional kitchens.

Directed Heat Broiling

The oven broiler uses intense radiant heat from above, providing consistent, even browning ideal for achieving perfect directed heat broiling on bread or meats. Infrared salamanders emit concentrated infrared radiation, resulting in rapid surface caramelization and crisping with precise temperature control for high-quality toasting results.

Salamander Toasting Intensity

Infrared salamanders deliver intense radiant heat that enables rapid and even toasting, producing a perfectly caramelized surface without drying out the interior. Unlike oven broilers, salamanders focus high-temperature energy directly onto the food, resulting in faster cooking times and superior browning control.

Dual-Element Crisping

Oven broilers and infrared salamanders both excel in toasting with dual-element crisping, where the broiler uses radiant heat from above to achieve even browning, while the infrared salamander employs concentrated infrared rays for rapid, precise crust formation. The dual-element crisping in infrared salamanders allows faster heat penetration and enhanced caramelization compared to traditional oven broilers, making them ideal for high-volume culinary applications.

Infrared Sear-Level Toasting

Infrared salamanders deliver intense, focused heat enabling precise sear-level toasting with faster surface caramelization compared to oven broilers. Their infrared elements provide consistent, high-temperature output ideal for achieving crisp textures and rich browning in shorter times, optimizing efficiency in professional kitchens.

Broiler Caramelization Efficiency

Oven broilers achieve caramelization through intense, direct radiant heat that efficiently browns the surface of bread and other foods, enhancing flavor and texture. Infrared salamanders provide more precise temperature control and faster heat response, but their caramelization efficiency depends on the wavelength and intensity of the infrared emission.

Flash Finish Crusting

Oven broilers and infrared salamanders both achieve Flash Finish Crusting by rapidly applying intense heat to the surface, but infrared salamanders offer more precise temperature control and faster heat-up times, resulting in evenly toasted crusts without overcooking the interior. The concentrated infrared radiation from salamanders enhances flavor development through Maillard reactions, providing superior browning and crispness compared to conventional oven broilers.

Fast-Ramp Toast Profile

Oven broilers provide a fast-ramp toast profile by using high, direct heat, quickly crisping surfaces and achieving uniform browning ideal for toasting bread and small pastries. Infrared salamanders offer even faster heat-up times with precise control, delivering rapid, intense heat that caramelizes sugars efficiently while minimizing moisture loss for perfectly toasted results.

Vertical Salamander Heat Zoning

Infrared salamanders provide precise vertical heat zoning for toasting, ensuring even browning and quicker cooking times compared to traditional oven broilers. The focused infrared radiation targets the surface uniformly, minimizing hot spots and reducing energy consumption during the toasting process.

Oven Broiler vs Infrared Salamander for toasting. Infographic

cookingdiff.com

cookingdiff.com