Toasting offers precise, even browning and faster preparation for breakfast foods compared to conveyor-belting, which provides higher volume but can compromise texture and consistency. Toasting preserves the crispness and flavor of bread, bagels, and English muffins, while conveyor-belting tends to produce less uniform results. For quality-focused breakfast service, toasting remains the preferred method over conveyor-belt systems.

Table of Comparison

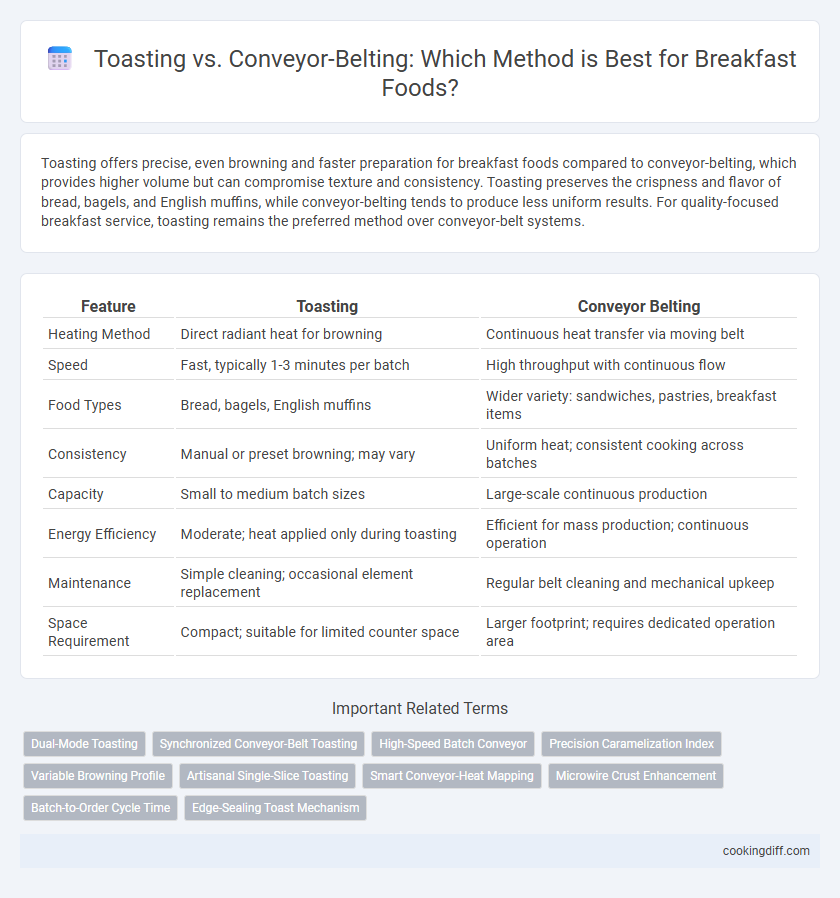

| Feature | Toasting | Conveyor Belting |

|---|---|---|

| Heating Method | Direct radiant heat for browning | Continuous heat transfer via moving belt |

| Speed | Fast, typically 1-3 minutes per batch | High throughput with continuous flow |

| Food Types | Bread, bagels, English muffins | Wider variety: sandwiches, pastries, breakfast items |

| Consistency | Manual or preset browning; may vary | Uniform heat; consistent cooking across batches |

| Capacity | Small to medium batch sizes | Large-scale continuous production |

| Energy Efficiency | Moderate; heat applied only during toasting | Efficient for mass production; continuous operation |

| Maintenance | Simple cleaning; occasional element replacement | Regular belt cleaning and mechanical upkeep |

| Space Requirement | Compact; suitable for limited counter space | Larger footprint; requires dedicated operation area |

Introduction: Comparing Toasting and Conveyor-Belting

Toasting and conveyor-belting are two popular methods used in preparing breakfast foods, each offering unique advantages in texture and speed. Understanding the differences between these techniques is essential for optimizing breakfast preparation efficiency and quality.

- Toasting - Utilizes radiant heat to evenly brown bread and pastries, enhancing flavor and crunchiness.

- Conveyor-belting - Continuously moves food items through a heated chamber for consistent cooking and higher throughput.

- Cooking Time - Toasting typically requires shorter batch processing, while conveyor-belting supports large volume output during busy breakfast hours.

Choosing between toasting and conveyor-belting depends on balancing speed, texture preference, and serving volume in breakfast food production.

How Toasting Works: A Traditional Approach

Toasting uses radiant heat elements to brown the surface of bread or breakfast foods by causing Maillard reactions, which enhance flavor and texture. Traditional toasters rely on electric heating coils or gas flames to evenly heat each slice, producing a crispy exterior while maintaining a soft interior. This method allows precise control over browning levels, ideal for quick, consistent results without the need for conveyor belts or extended cooking times.

Understanding Conveyor-Belting in Breakfast Preparation

Conveyor-belting in breakfast preparation offers uniform heat distribution, ensuring consistent toasting of bread, bagels, and English muffins. This method speeds up production, accommodating high-volume demand in commercial kitchens and cafeterias.

The conveyor system's adjustable speed and temperature controls provide precise customization for varying bread types and desired crispness levels. Compared to traditional toasting, conveyor-belting reduces manual handling, minimizing food waste and enhancing operational efficiency.

Speed and Efficiency: Which Method Wins?

Conveyor-belting systems can toast breakfast foods at a continuous pace, handling large volumes efficiently with consistent heat distribution that reduces cooking time. Traditional toasting methods often require manual handling, which slows down the process and limits throughput. In commercial kitchens, conveyor-belting clearly outperforms in speed and energy efficiency, making it ideal for high-demand environments.

Consistency and Quality of Toasted Foods

Toasting using traditional toasters ensures even heat distribution, resulting in consistently browned and crispy breakfast foods with minimal risk of uneven cooking. Conveyor-belting systems may create varying toast textures due to inconsistent speed and heat exposure across the conveyor belt surface.

Consistent quality in toasted foods relies heavily on precise temperature control, which traditional toasters typically maintain better than conveyor-belt machines. Conveyor-belting can cause some slices to be under-toasted or over-toasted, reducing overall product uniformity and consumer satisfaction.

Energy Consumption and Environmental Impact

How does toasting compare to conveyor-belting in terms of energy consumption and environmental impact for breakfast foods? Toasting typically uses less energy as it directly applies heat to the food, resulting in faster cooking times and reduced electricity usage. Conveyor-belting systems consume more power due to continuous belt movement and longer cooking durations, leading to a higher carbon footprint.

Versatility for Different Breakfast Foods

Toasting offers precise control over heat distribution, making it ideal for a wide variety of breakfast foods such as bagels, English muffins, and artisan breads. Conveyor-belting excels in handling high volumes consistently, yet it may lack the nuanced heat control required for diverse breakfast items.

- Versatility in Food Types - Toasting accommodates delicate items like croissants and thick-cut bread with adjustable heat settings.

- Consistent Throughput - Conveyor belts optimize speed and quantity, perfect for fast-paced breakfast service.

- Texture and Crust Quality - Toasting enhances texture by delivering even browning and crisp crusts on various bread products.

Maintenance and Cleaning Considerations

Toasting devices generally require less frequent deep cleaning compared to conveyor-belt systems, as their exposed surfaces and removable crumb trays simplify routine maintenance. Conveyor-belting breakfast equipment demands regular cleaning of belts and internal components to prevent food buildup and ensure consistent hygiene standards.

Maintenance of conveyor belts often involves dismantling parts to thoroughly clean crevices where grease and crumbs accumulate, increasing downtime and labor costs. Toasting machines benefit from straightforward access to heating elements and catch trays, allowing quick removal of debris and reducing contamination risk. Proper cleaning protocols for both systems are essential to maintain operational efficiency and prolong device lifespan in commercial kitchens.

Cost Analysis: Toasting vs Conveyor-Belting

Toasting breakfast foods generally incurs lower initial costs compared to conveyor-belting systems, which require significant investment in equipment and installation. However, conveyor-belting offers higher throughput and energy efficiency, potentially reducing long-term operational expenses.

- Initial Investment - Toasting machines have a lower upfront cost, making them suitable for small-scale operations.

- Operational Efficiency - Conveyor-belting systems streamline continuous cooking processes, improving productivity and reducing labor costs.

- Energy Consumption - Conveyor-belting devices typically consume less energy per unit processed, offering savings over time despite higher capital expenditure.

Related Important Terms

Dual-Mode Toasting

Dual-mode toasting combines the speed and even heat distribution of conveyor-belting with the artisanal quality of traditional toasting, ensuring consistently crisp textures and enhanced flavor profiles for breakfast foods. This hybrid approach optimizes energy efficiency and throughput while maintaining precise control over browning levels, ideal for high-volume foodservice environments.

Synchronized Conveyor-Belt Toasting

Synchronized conveyor-belt toasting ensures uniform browning and precise timing for breakfast foods by coordinating belt speed and heat distribution, reducing inconsistencies common in traditional toasters. This method enhances efficiency in high-volume settings, maintaining product quality while minimizing waste and energy consumption.

High-Speed Batch Conveyor

High-speed batch conveyor toasting systems deliver consistent, evenly browned breakfast foods at a rapid pace, outperforming traditional conveyor-belting by optimizing heat distribution and reducing cycle times. These systems enable precise control over toasting parameters, ensuring enhanced product quality and higher throughput in commercial kitchen environments.

Precision Caramelization Index

The Precision Caramelization Index in toasting provides consistent and controlled browning, ensuring uniform caramelization of breakfast foods compared to conveyor-belting systems that often result in uneven heat distribution and variable texture. This precise control enhances flavor development and visual appeal, making toasting superior for achieving optimal breakfast food quality.

Variable Browning Profile

Toasting offers a variable browning profile that allows precise control over crust color and texture, enhancing flavor complexity for breakfast items like bread and bagels. Conveyor-belting systems typically produce uniform browning but lack the adaptability needed for customizable crispness and visual appeal.

Artisanal Single-Slice Toasting

Artisanal single-slice toasting delivers precise heat control and superior browning ideal for breakfast foods, enhancing flavor and texture far beyond the uniform, mass-produced results of conveyor-belting systems. This method preserves the artisanal quality and craftsmanship, providing a customizable toast profile that meets diverse consumer preferences in gourmet breakfast settings.

Smart Conveyor-Heat Mapping

Smart Conveyor-Heat Mapping technology enhances conveyor-belting systems by ensuring uniform temperature distribution, significantly improving the consistency and quality of breakfast foods like toast, waffles, and bagels. This advanced heat control reduces uneven cooking and recalls, outperforming traditional toasting methods through precise thermal management and real-time monitoring.

Microwire Crust Enhancement

Microwire crust enhancement offers superior browning and crispiness compared to traditional conveyor-belting methods by directly applying intense, focused heat to breakfast foods. This technology improves texture and flavor without compromising cooking speed, making it ideal for consistent, high-quality toasting in commercial kitchens.

Batch-to-Order Cycle Time

Batch-to-order cycle time for toasting breakfast foods is significantly shorter with toasters compared to conveyor-belting systems, enabling faster product turnaround and minimizing wait times. Toasters achieve rapid heat distribution and consistent browning, optimizing efficiency for small to medium batch sizes in fast-paced foodservice environments.

Toasting vs Conveyor-belting for breakfast foods. Infographic

cookingdiff.com

cookingdiff.com