Toasting grains enhances flavor and aroma through controlled heat application, while cryogenic toasting uses ultra-low temperatures to alter texture without traditional browning. Toasting intensifies nutty and caramel notes by promoting Maillard reactions, whereas cryogenic methods preserve delicate compounds and prevent moisture loss. Selecting between these techniques depends on desired flavor complexity and texture outcomes in grain processing.

Table of Comparison

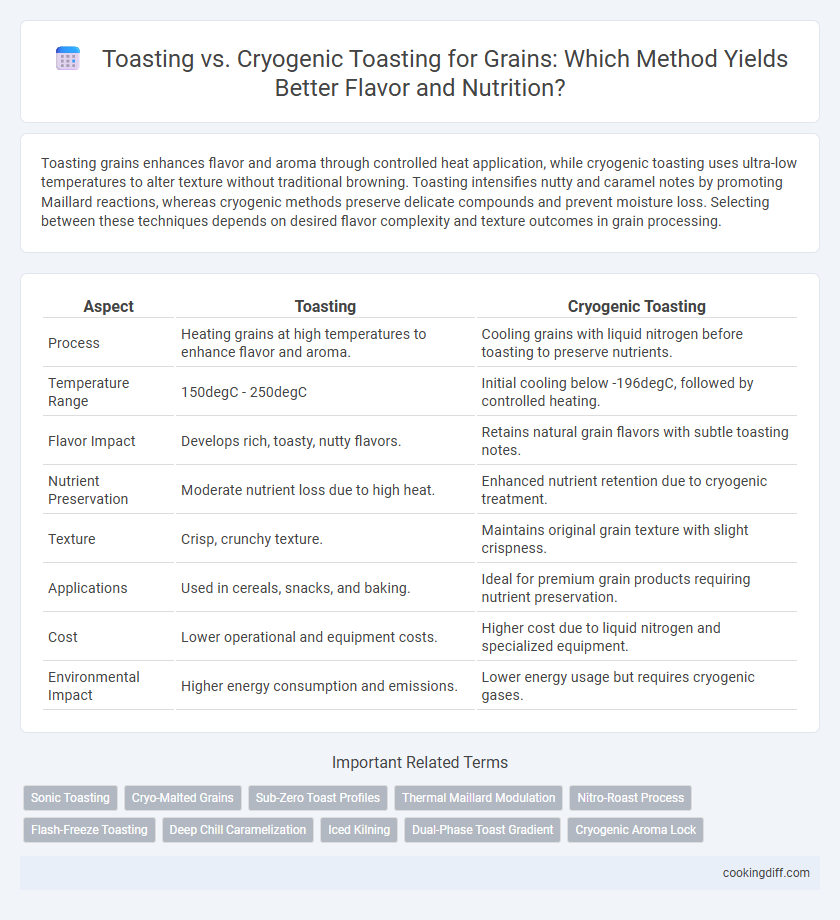

| Aspect | Toasting | Cryogenic Toasting |

|---|---|---|

| Process | Heating grains at high temperatures to enhance flavor and aroma. | Cooling grains with liquid nitrogen before toasting to preserve nutrients. |

| Temperature Range | 150degC - 250degC | Initial cooling below -196degC, followed by controlled heating. |

| Flavor Impact | Develops rich, toasty, nutty flavors. | Retains natural grain flavors with subtle toasting notes. |

| Nutrient Preservation | Moderate nutrient loss due to high heat. | Enhanced nutrient retention due to cryogenic treatment. |

| Texture | Crisp, crunchy texture. | Maintains original grain texture with slight crispness. |

| Applications | Used in cereals, snacks, and baking. | Ideal for premium grain products requiring nutrient preservation. |

| Cost | Lower operational and equipment costs. | Higher cost due to liquid nitrogen and specialized equipment. |

| Environmental Impact | Higher energy consumption and emissions. | Lower energy usage but requires cryogenic gases. |

Understanding Traditional Toasting for Grains

What distinguishes traditional toasting from cryogenic toasting when processing grains? Traditional toasting involves heating grains at moderate temperatures to enhance flavor, aroma, and color through Maillard reactions and caramelization. This method effectively develops complex taste profiles but may result in some nutrient loss compared to cryogenic toasting, which preserves more nutrients by using extremely low temperatures.

What Is Cryogenic Toasting?

Cryogenic toasting involves rapidly freezing grains using liquid nitrogen before subjecting them to a controlled toasting process, preserving the structural integrity and enhancing flavor profiles. Unlike traditional toasting, this method minimizes damage to the grain's cellular structure, resulting in improved texture and increased nutritional retention. Cryogenic toasting is especially effective for specialty grains used in high-quality baking and brewing applications.

Key Differences: Conventional vs. Cryogenic Toasting

Conventional toasting uses high heat for rapid flavor development in grains, while cryogenic toasting employs ultra-low temperatures to preserve nutritional value and enhance aroma. Cryogenic toasting minimizes oxidation and maintains grain integrity, contrasting with conventional methods that can cause nutrient loss and structural damage. The choice between these methods impacts the final product's taste profile, texture, and nutritional quality.

Impact on Flavor Profiles

Toasting grains intensifies their nutty and caramelized flavors by applying controlled heat, whereas cryogenic toasting preserves the grain's natural aroma through rapid freezing. This contrast leads to distinct flavor profiles, with traditional toasting enhancing richness and cryogenic methods maintaining freshness.

- Toasting enhances Maillard reactions - promotes complex, roasted flavor compounds in grains.

- Cryogenic toasting limits thermal degradation - retains original grain aroma and subtle sweet notes.

- Flavor intensity varies - toasting produces deeper, bolder flavors while cryogenic preserves delicate nuances.

Choosing between toasting and cryogenic toasting depends on the desired flavor character in the final product.

Nutritional Changes: Toasting vs. Cryogenic Methods

Toasting grains induces Maillard reactions that can decrease some heat-sensitive nutrients but enhance flavor profiles and antioxidant levels. Cryogenic toasting preserves the nutritional integrity by minimizing thermal degradation through rapid freezing and low-temperature processing.

- Enhanced Antioxidant Activity - Toasting increases antioxidant compounds like melanoidins formed during Maillard reactions.

- Nutrient Retention - Cryogenic methods better retain heat-sensitive vitamins and amino acids compared to conventional toasting.

- Flavor and Texture Impact - Toasting improves grain flavor and texture, whereas cryogenic toasting primarily maintains original sensory properties.

Texture and Appearance Comparison

Toasting grains enhances their texture by creating a crisp, crunchy exterior, while cryogenic toasting preserves a softer, more pliable interior. The appearance after toasting is typically darker and more uniform, whereas cryogenic toasting results in a lighter, less browned surface.

- Texture Crunchiness - Traditional toasting produces a hard, crunchy texture ideal for snacking.

- Texture Softness - Cryogenic toasting maintains an inner softness, retaining some natural grain moisture.

- Appearance Coloration - Conventional toasting yields a deep golden to brown color due to Maillard reactions.

Equipment and Process Requirements

| Equipment Requirements | Toasting utilizes standard roasting machines with controlled heat settings to achieve uniform grain color, while cryogenic toasting requires specialized chambers equipped with liquid nitrogen cooling systems to rapidly freeze grains during processing. |

| Process Requirements | Conventional toasting involves gradual heating at temperatures between 150-200degC to develop flavor and color, whereas cryogenic toasting incorporates rapid temperature changes to minimize thermal degradation and preserve nutritional integrity of grains. |

| Operational Complexity | Toasting systems are relatively simple with easy temperature adjustments; cryogenic toasting demands advanced monitoring and safety protocols due to handling of ultra-low temperatures and cryogenic gases. |

Energy Efficiency and Environmental Impact

Toast processing of grains typically consumes less energy than cryogenic toasting because it operates at moderate temperatures without the need for expensive refrigerants. This efficiency reduces greenhouse gas emissions, making conventional toasting more environmentally friendly in many contexts.

Cryogenic toasting uses liquid nitrogen or carbon dioxide to rapidly cool and toast grains, which requires substantial energy to produce and maintain these gases. The high energy demand and potential release of greenhouse gases during gas production can increase the environmental footprint of cryogenic methods compared to traditional toasting.

Industrial Applications and Scalability

Industrial applications favor toasting for grains due to its scalability and cost-effectiveness, allowing large batch processing with consistent heat distribution. Cryogenic toasting, while offering precise temperature control and preservation of grain nutrients, presents challenges in scalability due to high operational costs and complex infrastructure requirements.

Toasting systems can be integrated into continuous production lines, enhancing throughput and minimizing downtime, which is essential for large-scale grain processing facilities. Cryogenic toasting is better suited for specialized or smaller scale applications where grain quality and biochemical integrity are prioritized over volume.

Related Important Terms

Sonic Toasting

Sonic toasting employs ultrasonic waves to precisely heat grains, preserving nutritional content and enhancing flavor without the intense heat exposure typical in cryogenic toasting. This technique contrasts with traditional cryogenic toasting, which relies on freezing grains to extreme temperatures, potentially causing structural damage and nutrient loss.

Cryo-Malted Grains

Cryo-malted grains undergo cryogenic toasting using liquid nitrogen to instantly freeze the grain, preserving enzyme activity and unique flavor profiles that traditional toasting can diminish at high heat. This process enhances malt quality by maintaining fermentable sugars and producing consistent, vibrant malt character favored in craft brewing.

Sub-Zero Toast Profiles

Sub-zero toasting profiles utilize cryogenic cooling to rapidly reduce grain temperature during toasting, preserving volatile aroma compounds and enhancing flavor complexity compared to traditional toasting methods. This technique minimizes thermal damage and oxidation, resulting in grains with improved sensory attributes and extended shelf life.

Thermal Maillard Modulation

Toasting grains enhances flavor through Maillard reactions by applying controlled heat, creating complex thermal Maillard modulation that develops aromas and color. Cryogenic toasting, using ultra-low temperatures, limits Maillard reaction progression, preserving raw grain characteristics while offering subtle flavor nuances without the full thermal transformation.

Nitro-Roast Process

The Nitro-Roast process combines cryogenic cooling with controlled toasting, preserving grain aroma and enhancing flavor complexity by minimizing heat degradation and oxidation. Compared to traditional toasting, this technique delivers a more consistent roast profile and improved sensory qualities, making it ideal for premium grain applications in brewing and distilling.

Flash-Freeze Toasting

Flash-freeze toasting combines rapid freezing with high-temperature exposure, preserving grain flavor and aroma by minimizing heat damage and moisture loss compared to traditional cryogenic toasting. This method enhances the Maillard reaction efficiency, resulting in a superior toasted profile with uniform color and improved shelf stability.

Deep Chill Caramelization

Deep Chill Caramelization achieved through cryogenic toasting preserves the grain's structural integrity while enhancing complex flavor profiles by applying ultra-low temperatures during the toasting process. In contrast, traditional toasting relies on consistent heat exposure, which can cause more extensive Maillard reactions but often compromises the grain's texture and subtle aromatic compounds.

Iced Kilning

Iced kilning, a specialized form of toasting, uses controlled low-temperature airflows to enhance grain flavor profiles without the harshness typical of cryogenic toasting, preserving delicate aromatic compounds. This method optimizes Maillard reactions and enzymatic activity, delivering a balanced color development and improved malt extract yield compared to traditional cryogenic approaches.

Dual-Phase Toast Gradient

Dual-phase toast gradient in toasting grains combines initial low-temperature drying with a higher-temperature finish, enhancing flavor complexity and aroma development compared to cryogenic toasting which primarily uses rapid freezing to preserve grain integrity without extensive Maillard reactions. This method optimizes enzyme activation and starch modification, resulting in superior malt character and mouthfeel in brewed products.

Toasting vs Cryogenic toasting for grains. Infographic

cookingdiff.com

cookingdiff.com