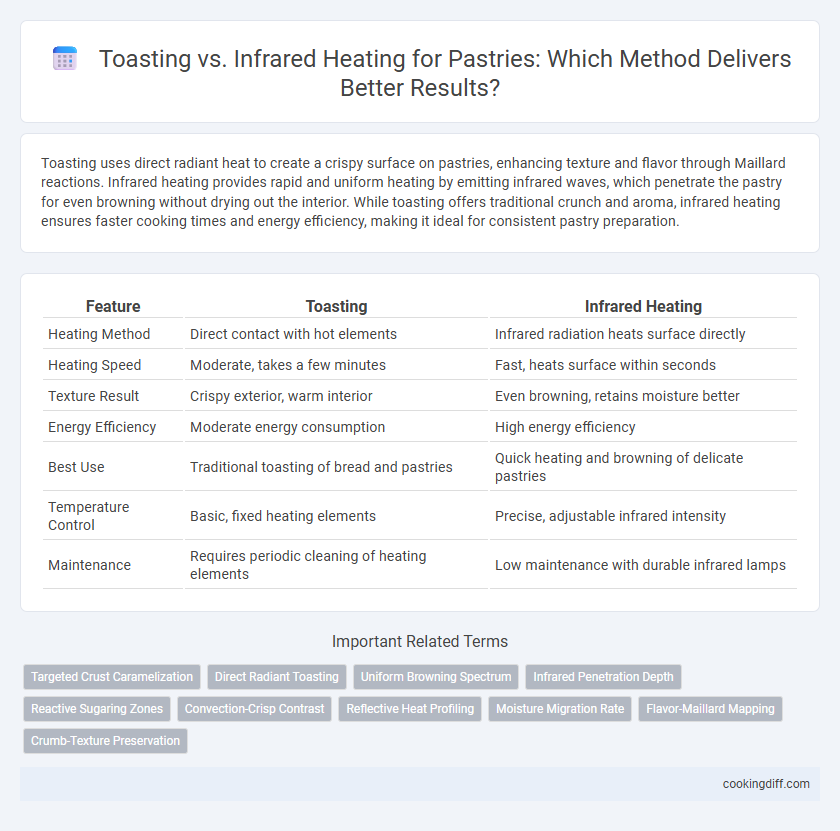

Toasting uses direct radiant heat to create a crispy surface on pastries, enhancing texture and flavor through Maillard reactions. Infrared heating provides rapid and uniform heating by emitting infrared waves, which penetrate the pastry for even browning without drying out the interior. While toasting offers traditional crunch and aroma, infrared heating ensures faster cooking times and energy efficiency, making it ideal for consistent pastry preparation.

Table of Comparison

| Feature | Toasting | Infrared Heating |

|---|---|---|

| Heating Method | Direct contact with hot elements | Infrared radiation heats surface directly |

| Heating Speed | Moderate, takes a few minutes | Fast, heats surface within seconds |

| Texture Result | Crispy exterior, warm interior | Even browning, retains moisture better |

| Energy Efficiency | Moderate energy consumption | High energy efficiency |

| Best Use | Traditional toasting of bread and pastries | Quick heating and browning of delicate pastries |

| Temperature Control | Basic, fixed heating elements | Precise, adjustable infrared intensity |

| Maintenance | Requires periodic cleaning of heating elements | Low maintenance with durable infrared lamps |

Introduction to Toasting and Infrared Heating

Toasting uses direct heat to brown and crisp pastry surfaces, enhancing texture and flavor through Maillard reactions. This method provides controlled, even heating ideal for finishing pastries with a desirable golden crust.

Infrared heating employs radiant energy to heat pastries rapidly, penetrating surfaces without relying on air circulation. It offers efficient energy use and precise temperature control, making it suitable for delicate pastry applications requiring quick, uniform cooking.

How Toasting Works: Principles and Methods

Toasting operates by applying direct radiant heat to the surface of pastries, causing Maillard reactions that create a crisp, browned exterior and enhance flavor complexity. This process typically involves convection currents and conduction when the pastry contacts heated surfaces inside the toaster.

Infrared heating emits electromagnetic waves that penetrate the pastry's surface, rapidly elevating temperature and ensuring even browning without over-drying the interior. Unlike traditional toasting, infrared methods provide precise control over heat intensity and distribution for consistent pastry texture.

Understanding Infrared Heating Technology

Infrared heating technology uses electromagnetic waves to directly heat the surface of pastries, resulting in faster and more even toasting compared to conventional methods. This precise heat transfer minimizes moisture loss, preserving the pastry's texture while enhancing browning efficiency.

- Direct Surface Heating - Infrared waves penetrate the pastry surface, providing uniform heat distribution without overheating the interior.

- Energy Efficiency - Infrared technology consumes less energy by focusing heat where it's needed, reducing cooking time and operational costs.

- Enhanced Browning - The precise control of infrared wavelengths promotes Maillard reactions, improving the color and flavor profile of pastries.

Flavor and Texture Differences in Pastries

| Toasting | Enhances flavor by caramelizing sugars on the pastry surface, creating a rich, toasted aroma and a slightly crispy crust. |

| Infrared Heating | Provides even heating that preserves moisture inside the pastry, resulting in a soft texture with less pronounced caramelization. |

| Flavor Comparison | Toasting develops deeper, nuttier notes due to Maillard reactions, while infrared heating maintains a more subtle, natural pastry flavor. |

| Texture Comparison | Toasting creates a firmer, crunchier outer layer contrasted with a tender interior, whereas infrared heating yields a uniformly soft and moist pastry. |

Energy Efficiency: Toasting vs Infrared Heating

Toasting generally consumes less energy than infrared heating when warming pastries due to targeted heat application and reduced preheating time. Infrared heating, while effective for uniform browning, often requires higher energy input for continuous operation.

- Lower Power Consumption - Toasting appliances typically use lower wattage compared to infrared heaters, resulting in reduced energy usage.

- Faster Heat Transfer - Toasting delivers heat directly to the pastry surface, minimizing energy waste and shortening heating duration.

- Energy Loss in Infrared - Infrared heating may cause heat dispersion to surrounding air, decreasing overall energy efficiency in pastry preparation.

Time and Convenience: Which Method is Faster?

Toasting typically heats pastries faster than infrared heating due to direct contact with the heating element, reducing overall preparation time. This method is especially convenient for quick snacks and small batches.

Infrared heating, while slower to warm the interior evenly, provides consistent heat distribution that prevents over-toasting the exterior. For larger quantities or more delicate pastries, infrared heating may offer better quality results. However, in terms of pure speed and convenience, toasting remains the more efficient choice for rapid preparation.

Equipment and Maintenance Considerations

Toasting equipment for pastries typically requires regular cleaning and occasional replacement of heating elements to maintain consistent browning, while infrared heating systems often feature sealed units that reduce maintenance frequency. Infrared heaters provide precise temperature control, minimizing equipment wear compared to traditional toasters that may experience uneven heat distribution. Choosing between toasting and infrared heating depends on balancing the ease of upkeep with equipment durability and repair costs.

Impact on Nutritional Value of Pastries

How does toasting compare to infrared heating in preserving the nutritional value of pastries? Toasting typically uses direct heat that can degrade heat-sensitive nutrients like vitamins B and C. Infrared heating offers a more uniform cooking process, minimizing nutrient loss and maintaining the pastry's overall nutritional profile.

Cost Comparison: Initial and Long-term Expenses

Toasting systems generally require higher initial investment compared to infrared heating units but offer lower long-term maintenance costs. Infrared heating devices have a cheaper upfront cost but may incur higher energy consumption and replacement expenses over time.

- Initial Cost Difference - Toasting equipment often costs 20-30% more to purchase and install than infrared heaters for pastry applications.

- Energy Efficiency - Infrared heating tends to consume 10-15% more energy, increasing operational expenses in the long run.

- Maintenance and Durability - Toasting systems typically have longer lifespans and fewer repairs, reducing total cost of ownership.

Choosing between toasting and infrared heating depends on balancing upfront investment with ongoing operational costs for pastry production.

Related Important Terms

Targeted Crust Caramelization

Toasting delivers targeted crust caramelization by applying direct, consistent heat that enhances Maillard reactions, resulting in a crispier, golden-brown exterior on pastries. Infrared heating, while effective for overall warming, often lacks the precision needed for uniform crust browning, making toasting the preferred method for achieving the ideal caramelized texture.

Direct Radiant Toasting

Direct radiant toasting delivers intense, focused heat that rapidly caramelizes pastry surfaces, enhancing flavor and texture more effectively than infrared heating. Unlike infrared methods, which distribute heat more diffusely, direct radiant toasting ensures precise browning and crispness essential for high-quality pastries.

Uniform Browning Spectrum

Toasting provides a more uniform browning spectrum on pastries by evenly distributing heat through radiant and convective means, enhancing texture and flavor without burning. Infrared heating, while faster, often creates hot spots that lead to uneven browning and inconsistent pastry quality.

Infrared Penetration Depth

Infrared heating offers deeper penetration into pastries, ensuring uniform internal cooking and enhanced moisture retention compared to surface-level toasting. This deeper heat distribution improves texture and flavor by gently heating the pastry's core without overcooking the exterior.

Reactive Sugaring Zones

Toasting creates distinct reactive sugaring zones by applying direct, high heat that caramelizes sugars unevenly, enhancing flavor and texture in pastries. Infrared heating offers more uniform heat distribution but results in less pronounced caramelization and fewer visible sugaring zones, impacting the sensory appeal.

Convection-Crisp Contrast

Toasting uses convection heat to uniformly crisp pastries, creating a golden, crunchy texture that enhances flavor depth, whereas infrared heating primarily delivers direct radiant energy that can cook unevenly and lacks the same convection-crisp contrast. Convection toasting promotes consistent moisture evaporation and Maillard reaction on pastry surfaces, yielding superior crispiness compared to the more superficial heating of infrared methods.

Reflective Heat Profiling

Reflective heat profiling in toasting ensures even browning and crispiness by using radiant heat that targets pastry surfaces uniformly, unlike infrared heating which often creates hot spots due to its direct energy emission. This precise heat distribution enhances texture and flavor consistency, making toasting the preferred method for delicate pastries requiring gentle, controlled heat exposure.

Moisture Migration Rate

Toasting exhibits a higher moisture migration rate compared to infrared heating, accelerating the drying process and creating a crispier pastry surface. Infrared heating maintains internal moisture longer, resulting in a softer texture and reduced risk of over-drying during baking.

Flavor-Maillard Mapping

Toasting enhances flavor through the Maillard reaction by applying dry heat that triggers complex browning and caramelization, intensifying sweetness and nutty notes in pastries. Infrared heating offers precise temperature control but may result in less uniform Maillard browning, affecting the depth and distribution of flavor layers in baked goods.

Toasting vs Infrared Heating for pastries. Infographic

cookingdiff.com

cookingdiff.com