Cookie cutters provide consistent shapes for baking, while 3D printed cookie cutters offer customizable designs tailored to specific themes or intricate patterns. The precision of 3D printing allows for detailed and unique shapes that traditional cookie cutters may not achieve. Using 3D printed cutters can enhance creativity and personalization in pet-themed baking projects.

Table of Comparison

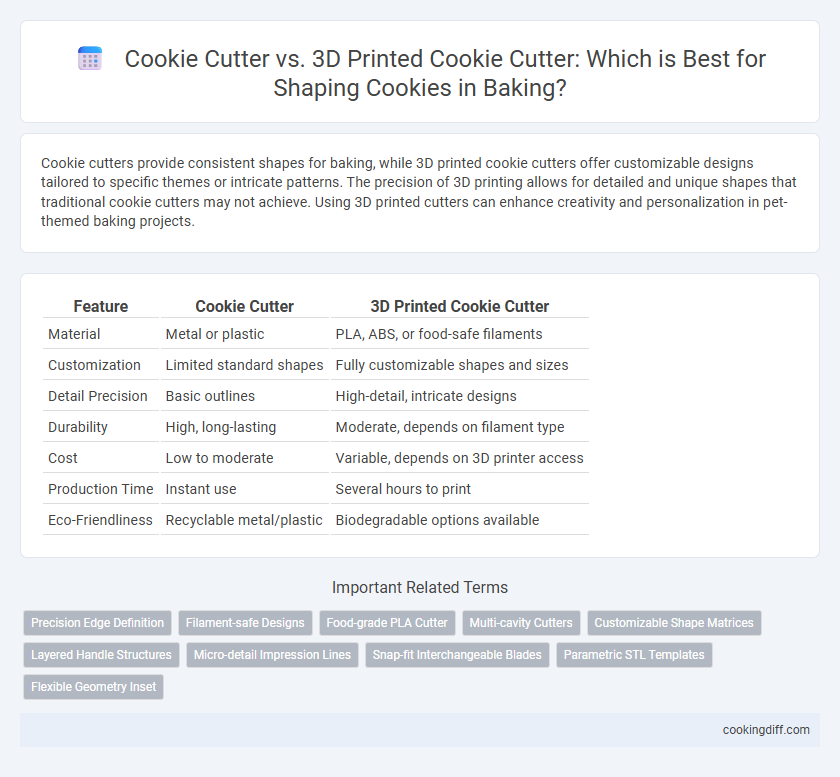

| Feature | Cookie Cutter | 3D Printed Cookie Cutter |

|---|---|---|

| Material | Metal or plastic | PLA, ABS, or food-safe filaments |

| Customization | Limited standard shapes | Fully customizable shapes and sizes |

| Detail Precision | Basic outlines | High-detail, intricate designs |

| Durability | High, long-lasting | Moderate, depends on filament type |

| Cost | Low to moderate | Variable, depends on 3D printer access |

| Production Time | Instant use | Several hours to print |

| Eco-Friendliness | Recyclable metal/plastic | Biodegradable options available |

Introduction to Cookie Cutters: Traditional vs 3D Printed

Traditional cookie cutters are typically made from metal or plastic, offering durable and reusable options for classic, well-defined shapes. 3D printed cookie cutters provide customizable designs, allowing intricate and personalized shapes that are difficult to achieve with conventional tools. Both methods have unique advantages, but 3D printing expands creative possibilities in cookie shaping and baking decoration.

Material Differences: Metal, Plastic, and 3D Printed Options

Metal cookie cutters offer durability and sharp edges for precise shapes, while plastic cutters provide lightweight and flexible options ideal for kids. 3D printed cookie cutters allow for customizable designs with varied materials such as PLA or PETG, balancing strength and food safety. Each material affects cutting performance, ease of cleaning, and longevity, making choice dependent on baking needs and design preferences.

Precision and Shape Variety: Which Offers More Creativity?

Traditional cookie cutters provide consistent shapes but are limited to standard designs, whereas 3D printed cookie cutters offer unparalleled precision and the ability to create intricate and customized shapes. This enhanced precision allows bakers to explore a wider variety of creative options in their baking projects.

- Precision - 3D printed cutters utilize digital models for exact dimensions, resulting in sharper and more detailed cookie shapes.

- Shape Variety - 3D printing enables complex and unique designs that go beyond the standard shapes available in traditional sets.

- Customization - Customers can design and print personalized cookie cutters tailored to specific themes or events.

3D printed cookie cutters thus unlock greater creative potential for bakers seeking precision and diversity in their cookie shapes.

Customization: Design Flexibility with 3D Printed Cookie Cutters

3D printed cookie cutters offer unparalleled customization, allowing bakers to create intricate and unique shapes that traditional metal cookie cutters cannot achieve. Design flexibility with CAD software enables precise adjustments and personalized details for every baking project.

- Complex Shapes - 3D printing allows for the production of detailed and complex cookie cutter designs beyond the capabilities of standard metal cutters.

- Personalized Designs - Custom logos, names, or seasonal themes can be easily integrated into 3D printed cutters for unique baking experiences.

- Rapid Prototyping - 3D printing enables quick iterations and modifications, perfect for bakers experimenting with new shapes or concepts.

Durability and Longevity: Traditional vs 3D Printed

Traditional cookie cutters, typically made from metal or sturdy plastic, offer high durability and can withstand repeated use and washing without losing shape. In contrast, 3D printed cookie cutters, often made from PLA or similar filaments, may be less durable and prone to wear or deformation over time.

The longevity of traditional cutters is enhanced by their resistance to heat and pressure during baking and cleaning processes. 3D printed cutters provide customization and complex shapes but generally require more careful handling to maintain their structural integrity. Material choice and printing quality significantly influence the lifespan of 3D printed cookie cutters compared to conventional options.

Food Safety: Comparing Material Safety Standards

Traditional cookie cutters are often made from food-grade stainless steel or plastic that meets established FDA safety standards, ensuring non-toxicity during baking. 3D printed cookie cutters require careful selection of food-safe filaments like PLA, but variability in printer cleanliness and material certification can pose food safety concerns.

- Material Certification - Stainless steel cookie cutters are typically certified for food contact, whereas 3D printed cutters depend on the filament's FDA compliance.

- Surface Porosity - 3D printed items may have microscopic crevices harboring bacteria, unlike the smooth surfaces of traditional cutters.

- Heat Resistance - Metal cutters withstand high oven temperatures safely; some 3D printing materials may warp or release harmful substances when heated.

Ease of Use: Handling and Cleaning Differences

Traditional cookie cutters are typically easier to handle due to their lightweight metal or plastic construction, providing a straightforward grip for shaping dough. Cleaning is simple since they usually have smooth edges and minimal crevices where dough can get stuck.

3D printed cookie cutters offer customizable shapes but often feature intricate designs that may complicate handling and require more careful dough pressing. Cleaning 3D printed cutters can be challenging as detailed patterns tend to trap bits of dough, necessitating thorough scrubbing or brushing.

Cost Comparison: Affordability and Long-Term Value

Which option offers better cost efficiency: traditional cookie cutters or 3D printed cookie cutters? Traditional cookie cutters tend to be more affordable upfront, with mass-produced designs costing just a few dollars each. However, 3D printed cookie cutters provide long-term value by allowing custom shapes without additional tooling costs, potentially saving money for frequent bakers and businesses needing personalized designs.

Environmental Impact: Sustainability of Materials and Processes

| Cookie Cutter Type | Material Sustainability | Environmental Impact of Production |

| Traditional Metal Cookie Cutters | Typically made from stainless steel or tinplate, these materials are durable but involve energy-intensive mining and refining processes. | Production requires significant energy and may contribute to pollution, though longevity reduces frequent replacement waste. |

| 3D Printed Cookie Cutters | Usually crafted from PLA or biodegradable plastics derived from renewable resources, offering improved sustainability over conventional plastics. | Printing consumes electricity primarily from local grids; the additive process minimizes material waste, enhancing eco-friendliness compared to subtractive manufacturing. |

Related Important Terms

Precision Edge Definition

Traditional cookie cutters offer reliable shapes but often lack the precision edge definition achieved by 3D printed cookie cutters, which utilize advanced design software to create intricate and sharply defined edges. This enhanced precision allows bakers to produce cookies with consistently detailed and clean shapes that are difficult to replicate using conventional metal or plastic cutters.

Filament-safe Designs

Filament-safe designs in 3D printed cookie cutters minimize filament wear and ensure durability against dough pressure compared to traditional metal cookie cutters. This technology allows for intricate, customizable shapes that maintain structural integrity while being food-safe and easy to clean.

Food-grade PLA Cutter

Food-grade PLA cookie cutters offer a safe, non-toxic option for creating intricate shapes with 3D printing technology, ensuring precise, customizable designs that traditional metal cutters cannot easily achieve. These eco-friendly PLA cutters withstand baking processes without degrading, making them ideal for detailed, reusable baking tools that comply with food safety standards.

Multi-cavity Cutters

Multi-cavity cookie cutters offer consistent shape replication for large batches, while 3D printed versions provide customizable designs with intricate details not achievable by traditional methods. The precision of 3D printing ensures uniform dough thickness and shape accuracy, enhancing both visual appeal and baking efficiency.

Customizable Shape Matrices

Customizable shape matrices in 3D printed cookie cutters enable intricate and personalized designs with high precision, surpassing the limited shape options available in traditional metal cookie cutters. This technology allows bakers to easily create unique and complex patterns tailored to specific themes or preferences, enhancing creativity and variety in baked goods.

Layered Handle Structures

Cookie cutters with layered handle structures offer enhanced grip and ergonomic comfort, while 3D printed cookie cutters enable precise customization of layered handle designs, optimizing usability and aesthetic appeal. The additive manufacturing process allows for intricate handle geometries that improve stability and reduce hand fatigue during repetitive baking tasks.

Micro-detail Impression Lines

Traditional cookie cutters create basic shapes but lack the precision to capture fine micro-detail impression lines, resulting in simpler designs. 3D printed cookie cutters utilize advanced modeling techniques to produce intricate micro-detail lines, enabling highly detailed and customizable cookie shapes with sharp, defined textures.

Snap-fit Interchangeable Blades

Snap-fit interchangeable blades in 3D printed cookie cutters offer customizable and precise shape options compared to traditional cookie cutters, enhancing baking creativity and efficiency. These innovative designs enable quick blade swaps without tools, making it easier to produce varied cookie shapes with consistent quality.

Parametric STL Templates

Parametric STL templates enable precise customization of 3D printed cookie cutters, allowing for scalable and intricate shapes that traditional cookie cutters cannot achieve. These templates offer bakers enhanced flexibility and repeatability in design, optimizing cookie shape accuracy and creativity.

Cookie cutter vs 3D printed cookie cutter for shapes Infographic

cookingdiff.com

cookingdiff.com