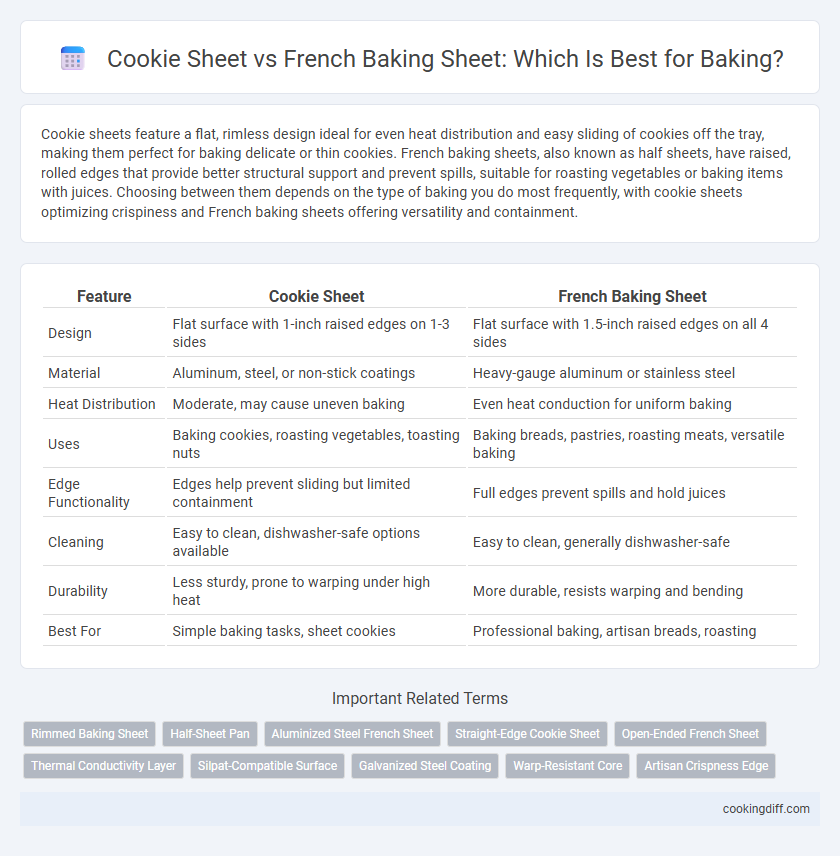

Cookie sheets feature a flat, rimless design ideal for even heat distribution and easy sliding of cookies off the tray, making them perfect for baking delicate or thin cookies. French baking sheets, also known as half sheets, have raised, rolled edges that provide better structural support and prevent spills, suitable for roasting vegetables or baking items with juices. Choosing between them depends on the type of baking you do most frequently, with cookie sheets optimizing crispiness and French baking sheets offering versatility and containment.

Table of Comparison

| Feature | Cookie Sheet | French Baking Sheet |

|---|---|---|

| Design | Flat surface with 1-inch raised edges on 1-3 sides | Flat surface with 1.5-inch raised edges on all 4 sides |

| Material | Aluminum, steel, or non-stick coatings | Heavy-gauge aluminum or stainless steel |

| Heat Distribution | Moderate, may cause uneven baking | Even heat conduction for uniform baking |

| Uses | Baking cookies, roasting vegetables, toasting nuts | Baking breads, pastries, roasting meats, versatile baking |

| Edge Functionality | Edges help prevent sliding but limited containment | Full edges prevent spills and hold juices |

| Cleaning | Easy to clean, dishwasher-safe options available | Easy to clean, generally dishwasher-safe |

| Durability | Less sturdy, prone to warping under high heat | More durable, resists warping and bending |

| Best For | Simple baking tasks, sheet cookies | Professional baking, artisan breads, roasting |

Overview: Cookie Sheet vs French Baking Sheet

| Type | Description | Key Features |

|---|---|---|

| Cookie Sheet | Flat baking sheet with a raised edge on one or two sides, designed for even heat distribution and crisp cookie edges. | Lightweight aluminum or stainless steel, easy slide-in and slide-out, ideal for uniform cookie baking. |

| French Baking Sheet (Half Sheet Pan) | Deeper pan with four raised edges, crafted from heavier gauge steel for durability and excellent heat conduction. | Non-stick surfaces common, versatile for roasting, baking bread, and cooking larger pastry batches, supports even browning. |

Key Design Differences

Cookie sheets and French baking sheets differ primarily in edge design and heat distribution, impacting baking outcomes. Cookie sheets feature one or two flat, low edges for easy removal of baked goods, while French baking sheets are characterized by their continuous, higher edges on all sides, resembling a shallow pan.

- Edge Design - Cookie sheets have one or two raised edges, which facilitate sliding cookies off, whereas French baking sheets have four raised edges for better containment of dough and batter.

- Heat Distribution - French baking sheets often provide more even heat conduction due to their thicker construction, ideal for crispy, uniform baking.

- Versatility - Cookie sheets are designed mainly for cookies and flat baked goods, while French baking sheets can handle a wider range of items including roast vegetables and sheet cakes.

Choosing between the two depends on the specific baking needs and desired results of the baker.

Material Comparison

Cookie sheets are typically made from aluminum or aluminized steel offering excellent heat conductivity and even baking, while French baking sheets are often constructed from heavier-gauge aluminized steel providing superior durability and consistent heat retention. The material differences impact baking results, with cookie sheets favoring faster heat transfer and French baking sheets delivering more uniform browning.

- Cookie Sheet Material - Aluminum ensures quick heat conduction, ideal for crisp cookies.

- French Baking Sheet Material - Heavy-gauge aluminized steel retains heat evenly, promoting consistent texture.

- Durability Comparison - French baking sheets resist warping better due to thicker metal composition.

Heat Distribution and Performance

Cookie sheets typically feature a flat, rimless design that allows for even heat distribution, making them ideal for baking cookies that require consistent browning. French baking sheets, or half sheets with slightly raised edges, offer superior heat retention and performance by promoting more uniform airflow around the baked goods.

The thicker aluminum construction of French baking sheets enhances heat conductivity, reducing hot spots and ensuring more predictable baking results. In contrast, the thinner metal of standard cookie sheets may lead to uneven cooking and occasional burning along the edges of delicate treats.

Baking Results: Texture and Browning

Cookie sheets, typically flat with a lip on one or two sides, promote even heat distribution, resulting in crisp edges and a softer center in baked goods. French baking sheets, featuring higher sides, encourage better air circulation and more uniform browning, ideal for cookies requiring consistent texture throughout.

The material and thickness of French baking sheets enhance heat retention, producing a golden-brown crust and a chewier interior. Cookie sheets may sometimes cause uneven browning due to thinner metal construction, affecting the final texture of the cookies.

Versatility for Different Recipes

Cookie sheets offer a flat surface without sides, making them ideal for cookies and baked goods that require even heat distribution. French baking sheets feature a slightly raised, angled edge that provides more structure, making them better suited for a wider variety of recipes including roasting and baking pastries.

- Cookie sheets excel in producing evenly baked cookies - Their flat design allows heat to circulate uniformly, preventing soggy bottoms.

- French baking sheets accommodate multiple cooking methods - The rimmed edges allow for containing juices and handling delicate recipes like roasted vegetables and sheet cakes.

- Both sheets vary in thickness and material - This affects heat retention and versatility across different baking applications.

Ease of Handling and Storage

Cookie sheets typically feature a flat surface with one or two raised edges, making them easier to slide cookies on and off but somewhat awkward to store due to their larger size and irregular shape. French baking sheets, also known as half-sheet pans, have uniform edges on all sides, allowing for more secure handling and stackable storage in typical kitchen cabinets.

The cookie sheet's open sides simplify transferring baked goods with a spatula but require more careful handling to avoid spills. French baking sheets provide enhanced stability when carrying or moving trays in and out of the oven due to their rimmed edges. Their standardized dimensions enable efficient stacking, optimizing storage space in limited kitchen environments.

Cleaning and Maintenance

Cookie sheets with flat surfaces and minimal edges are easier to clean since crumbs and residue don't get trapped in corners, making maintenance quick and efficient. French baking sheets feature raised edges, which can retain grease and baked-on food, requiring more thorough scrubbing or soaking to maintain cleanliness. Choosing a non-stick coating on either type simplifies cleaning by preventing stubborn food buildup and reducing the need for harsh detergents.

Price and Durability

Cookie sheets are generally more affordable, making them a budget-friendly option for everyday baking needs. French baking sheets, crafted from thicker materials and featuring rolled edges, offer superior durability and even heat distribution, which justifies their higher price point. Investing in a French baking sheet can enhance baking performance and longevity, especially for frequent bakers.

Related Important Terms

Rimmed Baking Sheet

Rimmed baking sheets, also known as cookie sheets, provide raised edges that prevent dough or batter from spilling, making them ideal for roasting and baking tasks requiring containment. French baking sheets offer thinner, sturdier aluminum construction with low lips for versatile baking and even heat distribution, preferred by professionals for crispier results and easier handling.

Half-Sheet Pan

A half-sheet pan, typically measuring 18 x 13 inches, is a versatile option favored in both home and professional baking for its balanced size and even heat distribution, making it ideal for cookies and pastries. French baking sheets, with their slightly thicker metal and rolled edges, offer superior durability and heat retention but may conduct heat less quickly than standard cookie sheets.

Aluminized Steel French Sheet

Aluminized steel French baking sheets feature a sturdy, warp-resistant construction that ensures even heat distribution and consistent browning, making them superior to standard cookie sheets for baking delicate pastries and cookies. Their rolled edges provide added strength and better heat conduction, enhancing overall baking performance and durability.

Straight-Edge Cookie Sheet

A straight-edge cookie sheet, also known as a cookie tray, features raised edges on all sides, preventing dough or batter from spilling over during baking, unlike traditional rimmed French baking sheets which have shallower, rolled edges designed for better airflow and crispier results. This design makes straight-edge cookie sheets ideal for baking items that require containment or liquid batter, offering versatility in both cookie and small pastry preparations.

Open-Ended French Sheet

Open-ended French baking sheets are designed with higher, straight edges that provide better air circulation around baked goods, making them ideal for even baking and crisping cookies. Unlike traditional cookie sheets with one or more closed sides, these sheets allow steam to escape, preventing sogginess and ensuring a perfect texture.

Thermal Conductivity Layer

Cookie sheets typically feature a thinner aluminum layer for faster heat conduction, promoting even baking and browning, while French baking sheets often use a heavier gauge steel with multiple thermal conductivity layers to provide more consistent heat distribution and superior temperature retention. The enhanced thermal conductivity layer in French baking sheets reduces hot spots, resulting in more uniform cookies or pastries with optimal texture and color.

Silpat-Compatible Surface

Cookie sheets often have raised edges that can interfere with silicone baking mats, whereas French baking sheets feature low, flat sides ideal for a Silpat-compatible surface, ensuring even heat distribution and easy removal of baked goods. The silicone-compatible design of French baking sheets prevents slipping and promotes consistent browning, making them preferred for delicate cookies and pastries.

Galvanized Steel Coating

Galvanized steel coating on cookie sheets provides enhanced resistance to rust and corrosion, making them durable for high-temperature baking tasks. French baking sheets, typically uncoated aluminum, offer superior heat conduction but lack the protective galvanized layer, affecting longevity and maintenance.

Warp-Resistant Core

A French baking sheet features a warp-resistant core, typically made from heavy-gauge aluminum, ensuring even heat distribution and preventing the pan from bending at high temperatures. In contrast, standard cookie sheets often lack this sturdy core, making them prone to warping and uneven baking results during extended or high-heat baking sessions.

Cookie Sheet vs French Baking Sheet for baking. Infographic

cookingdiff.com

cookingdiff.com