Metal sifters provide durability and a classic design that ensures consistent flour texture through a fine mesh screen, ideal for delicate baking tasks. Rotary flour sifters feature a crank handle mechanism that allows for quick and efficient sifting, reducing effort and preventing clumps in batter or dough. Choosing between the two depends on personal preference for speed versus control in achieving smooth, aerated flour for baking.

Table of Comparison

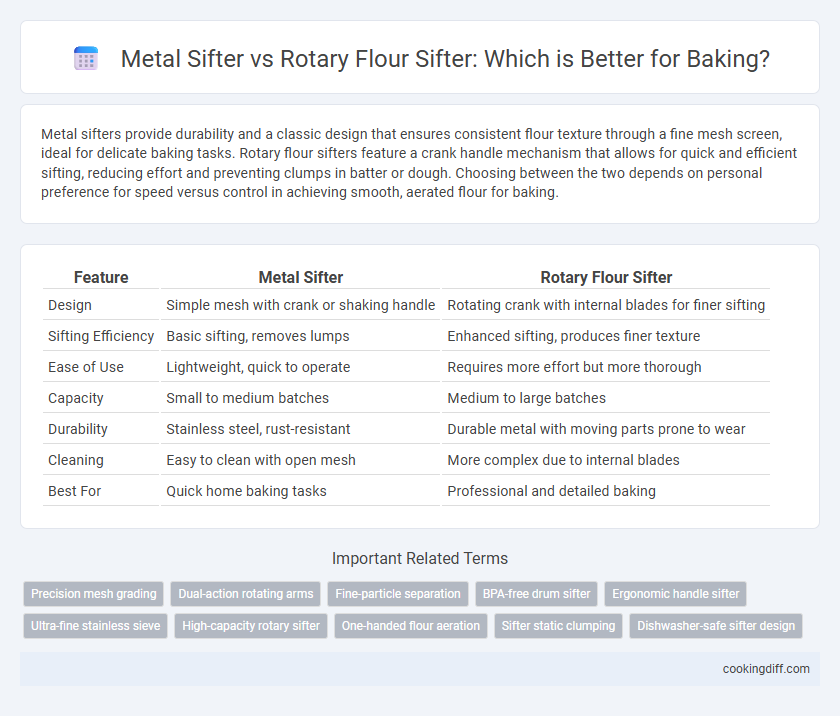

| Feature | Metal Sifter | Rotary Flour Sifter |

|---|---|---|

| Design | Simple mesh with crank or shaking handle | Rotating crank with internal blades for finer sifting |

| Sifting Efficiency | Basic sifting, removes lumps | Enhanced sifting, produces finer texture |

| Ease of Use | Lightweight, quick to operate | Requires more effort but more thorough |

| Capacity | Small to medium batches | Medium to large batches |

| Durability | Stainless steel, rust-resistant | Durable metal with moving parts prone to wear |

| Cleaning | Easy to clean with open mesh | More complex due to internal blades |

| Best For | Quick home baking tasks | Professional and detailed baking |

Introduction to Flour Sifters in Baking

What are the key differences between a metal sifter and a rotary flour sifter in baking? Metal sifters feature a simple design with a fine mesh screen that requires manual shaking to sift flour, providing consistent texture for cakes and pastries. Rotary sifters use a crank mechanism to push flour through the mesh, offering faster sifting and better control over flour aeration for delicate baked goods.

What is a Metal Sifter?

A metal sifter is a baking tool made from stainless steel or tin, designed to aerate and remove clumps from flour. It typically features a fine mesh screen and a handle-operated mechanism that shakes or taps the flour through the screen for uniform texture.

This type of sifter ensures even distribution of dry ingredients, improving dough consistency and resulting in lighter baked goods. Metal sifters are durable, easy to clean, and often preferred for their precision compared to rotary flour sifters.

What is a Rotary Flour Sifter?

A rotary flour sifter is a baking tool designed with a crank handle that rotates internal blades to sift flour evenly and efficiently. It separates clumps and aerates the flour, resulting in lighter and more consistent batter or dough. This type of sifter is preferred for its ease of use and ability to process large quantities of flour quickly compared to a traditional metal sifter.

Comparing Sifting Efficiency: Metal vs Rotary

Metal sifters typically offer faster flour sifting due to their simple mesh design, allowing flour to pass through with minimal effort. Rotary flour sifters use a crank mechanism to push flour through fine mesh, which can provide more consistent sifted texture and reduce clumps. However, rotary sifters may require more time and manual effort compared to metal sifters, impacting overall sifting efficiency based on baker preference and recipe requirements.

Ease of Use: Metal Sifter vs Rotary Sifter

The metal sifter features a straightforward design with a handle that requires a simple shaking motion, making it quick and easy to use for most bakers. Its durable construction ensures consistent performance without much effort or maintenance.

The rotary flour sifter offers more control with a crank mechanism that evenly distributes flour, ideal for intricate baking tasks requiring precision. However, it may demand more hand coordination and can be slightly slower to operate compared to the metal sifter. Both tools enhance baking accuracy, but the choice depends on user preference for speed versus control.

Cleaning and Maintenance Differences

Metal sifters are typically easier to clean due to their simple construction and fewer moving parts. Rotary flour sifters require more detailed maintenance to prevent flour buildup in the crank mechanism.

- Metal Sifter Cleaning - Can be washed quickly by hand or placed in a dishwasher without damage.

- Rotary Sifter Maintenance - Needs regular disassembly and thorough cleaning to avoid clogging.

- Durability Considerations - Metal sifters tend to resist rust and corrosion better than rotary sifters with exposed parts.

Sifting Speed and Consistency

Metal sifters typically offer faster sifting speed due to their wide mesh and simple crank mechanism, allowing larger quantities of flour to pass through quickly. Their sturdy design ensures consistent particle size, which helps in achieving uniform dough texture.

Rotary flour sifters provide more controlled sifting with a rotating handle that evenly distributes flour, improving consistency in smaller batches. The slower, deliberate process enhances precision but may require more time compared to metal sifters.

Durability and Material Quality

Metal sifters are typically crafted from stainless steel, offering superior durability and resistance to rust compared to rotary flour sifters, which often use thinner metals or plastic components. This robustness ensures metal sifters maintain their structural integrity and performance over prolonged use in baking environments.

- Material Composition - Metal sifters use high-grade stainless steel, enhancing longevity and corrosion resistance.

- Wear Resistance - Rotary flour sifters may show wear or bending due to thinner materials or plastic parts.

- Maintenance - Metal sifters are easier to clean and sustain quality after repeated use, preventing flour clumping or retention.

Best Uses: When to Choose Each Sifter

| Sifter Type | Best Uses |

|---|---|

| Metal Sifter | Ideal for quickly aerating flour and removing lumps when baking cakes, cookies, and pastries that require a light, consistent texture. |

| Rotary Flour Sifter | Best for sifting larger quantities of flour or dry ingredients in recipes like bread or layered cakes, where thorough mixing and fine texture are essential. |

Related Important Terms

Precision mesh grading

Metal sifters offer consistent precision mesh grading that ensures uniform flour texture, enhancing dough quality and baking consistency. Rotary flour sifters typically feature adjustable mesh sizes, allowing bakers to customize flour fineness for specific recipes, optimizing ingredient integration and final product texture.

Dual-action rotating arms

Metal sifters with dual-action rotating arms provide precise flour aeration and removal of lumps, enhancing batter consistency for baking. Rotary flour sifters also feature dual-action mechanisms, but their ergonomic design allows faster sifting while maintaining fine flour texture ideal for delicate pastries.

Fine-particle separation

Metal siftors produce consistent fine-particle separation by forcing flour through tightly spaced mesh screens, ensuring uniform texture for delicate baked goods. Rotary flour sifters use a crank mechanism to agitate the flour, effectively breaking up clumps and aerating ingredients, but may allow larger particles to pass through compared to metal mesh sifters.

BPA-free drum sifter

BPA-free metal sifters provide durable, rust-resistant performance ideal for precise flour aeration, while rotary flour sifters offer efficient, hands-on control with a comfortable grip for consistent sifting results. Choosing a BPA-free drum sifter ensures food safety by eliminating harmful chemicals, enhancing both the quality and healthfulness of baked goods.

Ergonomic handle sifter

Ergonomic handle sifters provide enhanced grip and comfort, reducing hand fatigue during extended baking sessions compared to traditional rotary flour sifters. Metal sifters with ergonomic designs offer durability and precision, ensuring consistent flour aeration while minimizing strain on the wrist.

Ultra-fine stainless sieve

The ultra-fine stainless steel sieve in metal sifters ensures precise flour aeration and removal of impurities, enhancing dough texture and consistency. Rotary flour sifters, while efficient for quick sifting, often feature coarser meshes, making ultra-fine stainless sifters ideal for delicate pastries requiring finer flour distribution.

High-capacity rotary sifter

High-capacity rotary sifters improve baking efficiency by quickly sifting large amounts of flour, preventing clumps and ensuring consistent texture. Unlike metal sifters, rotary models handle higher volumes with less effort, making them ideal for commercial baking or heavy home use.

One-handed flour aeration

Metal sifters provide quick, one-handed flour aeration through a simple squeeze mechanism that evenly distributes flour and removes lumps. Rotary flour sifters require both hands to turn the crank, making them less convenient for one-handed operation but offer consistent, fine sifting ideal for delicate baked goods.

Sifter static clumping

Metal sifters often cause static clumping due to friction between flour particles and the metal mesh, leading to uneven sifting. Rotary flour sifters, equipped with a crank mechanism and enclosed design, minimize static buildup and provide a consistent, clump-free flour texture essential for precise baking results.

Metal Sifter vs Rotary Flour Sifter for baking. Infographic

cookingdiff.com

cookingdiff.com