Traditional ovens provide consistent dry heat suitable for achieving a crispy crust and even browning in bread baking. Steam ovens introduce moisture during the baking process, creating a humid environment that promotes better oven spring, a softer crust, and improved crumb texture. Choosing between the two depends on the desired crust crispness and moisture retention in the final loaf.

Table of Comparison

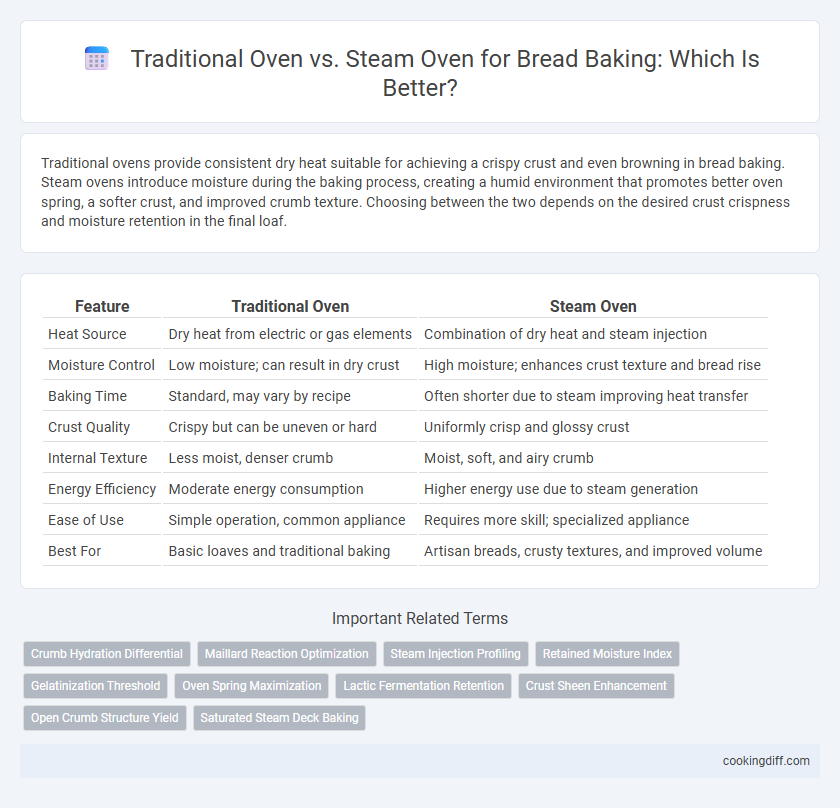

| Feature | Traditional Oven | Steam Oven |

|---|---|---|

| Heat Source | Dry heat from electric or gas elements | Combination of dry heat and steam injection |

| Moisture Control | Low moisture; can result in dry crust | High moisture; enhances crust texture and bread rise |

| Baking Time | Standard, may vary by recipe | Often shorter due to steam improving heat transfer |

| Crust Quality | Crispy but can be uneven or hard | Uniformly crisp and glossy crust |

| Internal Texture | Less moist, denser crumb | Moist, soft, and airy crumb |

| Energy Efficiency | Moderate energy consumption | Higher energy use due to steam generation |

| Ease of Use | Simple operation, common appliance | Requires more skill; specialized appliance |

| Best For | Basic loaves and traditional baking | Artisan breads, crusty textures, and improved volume |

Introduction: Traditional Ovens vs Steam Ovens

Traditional ovens use dry heat to bake bread, resulting in a crusty exterior and soft interior. Steam ovens inject moisture during baking, which enhances crust development and improves crumb texture. Comparing traditional and steam ovens highlights differences in moisture control, heat distribution, and baking efficiency.

How Traditional Ovens Work for Bread Baking

Traditional ovens use radiant heat from electric or gas sources to bake bread, creating a dry environment that promotes a crisp crust. The heat is distributed unevenly through natural convection, which can result in variable browning and texture.

- Radiant Heat - Traditional ovens rely on radiant heat to cook bread from the outside in, forming a crust while baking the interior.

- Dry Atmosphere - The lack of moisture in traditional ovens helps produce a firm and crunchy bread crust.

- Natural Convection - Heat circulates through natural convection, often causing hot spots that affect the evenness of bread baking.

How Steam Ovens Enhance Bread Baking

Steam ovens introduce precise humidity control during baking, resulting in bread with a crisp crust and moist interior. Unlike traditional ovens, steam ovens prevent the dough from drying out, enabling better oven spring and enhanced texture.

- Moisture retention - Steam ovens inject steam that keeps the crust hydrated, forming a glossy and crackly surface.

- Improved rise - The controlled steam environment promotes yeast activity, leading to a higher and lighter loaf.

- Even baking - Steam heat distribution reduces hot spots, ensuring uniform crumb structure and consistent bake.

Steam ovens elevate artisanal bread quality by optimizing humidity, temperature, and heat circulation for superior baking results.

Crust Development: Comparing Results

Steam ovens enhance crust development by maintaining a moist environment that allows for better oven spring and a crispier, shinier crust compared to traditional ovens. Traditional ovens often produce a thicker, harder crust due to dry heat but lack the same level of gloss and optimal texture achieved with steam.

- Steam Retention - Steam ovens trap moisture during baking, improving crust elasticity and color.

- Crust Thickness - Traditional ovens create a thicker crust due to rapid moisture evaporation.

- Texture and Gloss - Steam ovens yield a crisper crust with a shiny, appetizing appearance.

Interior Texture and Crumb Differences

Traditional ovens produce bread with a thicker, crunchier crust due to dry heat, which draws moisture from the dough's surface. The crumb tends to be denser and less moist compared to steam oven results.

Steam ovens maintain high humidity during baking, resulting in a thinner, glossier crust and a softer, more open crumb structure. This environment allows the dough to expand more fully, enhancing the bread's interior texture and moistness.

Flavor Profiles: Steam vs Dry Heat

Traditional ovens use dry heat, which produces a thicker, chewier crust and a robust, caramelized flavor in bread. Steam ovens inject moisture during baking, creating a crisp, glossy crust and enhancing the bread's aromatic complexity by preserving volatile compounds. The choice between steam and dry heat significantly affects the texture and flavor profile, with steam ovens delivering a lighter crumb and nuanced taste compared to the bold richness from dry heat baking.

Energy Efficiency and Baking Time

Traditional ovens generally consume more energy due to longer preheating times and extended baking durations, whereas steam ovens operate with shorter baking cycles and use moisture to enhance heat transfer efficiency. Energy efficiency in steam ovens also stems from their ability to maintain consistent temperature and humidity, reducing overall heat loss.

Steam ovens can cut baking time by up to 20%, which significantly lowers energy consumption compared to traditional ovens. The moisture in steam ovens accelerates dough expansion and crust formation, allowing for faster baking with less energy. Traditional ovens often require manual adjustments to maintain optimal humidity, leading to potential energy waste and inconsistent baking results.

Ease of Use and Maintenance

| Oven Type | Ease of Use | Maintenance |

|---|---|---|

| Traditional Oven | Simple controls with basic temperature settings; widely understood by most bakers. | Requires regular cleaning to remove burnt residues; fewer components reduce the chance of mechanical issues. |

| Steam Oven | Offers precise steam and temperature control, which can improve bread quality but requires familiarization. | Needs routine descaling and water reservoir cleaning to prevent mineral buildup and maintain optimal performance. |

Cost Analysis: Investment and Longevity

Which oven offers better long-term value for bread baking: traditional or steam? Traditional ovens typically require a lower initial investment but may lead to higher energy costs due to longer baking times. Steam ovens, although more expensive upfront, enhance bread quality and durability, potentially reducing replacement frequency and operational costs over time.

Related Important Terms

Crumb Hydration Differential

Traditional ovens create a drier baking environment resulting in a crust with lower moisture content and a denser crumb, while steam ovens maintain higher humidity, promoting better crumb hydration and a softer, more open texture. This differential in crumb hydration significantly impacts the bread's chewiness, shelf life, and overall mouthfeel.

Maillard Reaction Optimization

Traditional ovens provide a dry heat environment that enhances the Maillard reaction, resulting in a deeply browned crust and rich flavors in bread. Steam ovens introduce moisture, which delays crust formation, allowing for better oven spring but can reduce the intensity of Maillard browning unless steam is carefully controlled and then released to optimize crust development.

Steam Injection Profiling

Steam ovens enhance bread baking by injecting precise steam profiles that improve crust development and crumb texture through controlled humidity levels. Traditional ovens lack this capability, often resulting in less consistent crust quality and moisture retention.

Retained Moisture Index

Traditional ovens often result in lower Retained Moisture Index in bread due to dry heat exposure, causing crusts to form quickly and moisture to escape during baking. Steam ovens maintain higher Retained Moisture Index by injecting steam into the baking chamber, promoting moisture retention, enhanced crust texture, and extended freshness in bread.

Gelatinization Threshold

Traditional ovens typically reach temperatures that promote starch gelatinization in bread dough between 60degC and 70degC, creating a firm crust and soft crumb, while steam ovens maintain higher humidity, ensuring more even heat transfer and delaying crust formation to enhance gelatinization and improve bread volume and texture. The controlled moisture environment in steam ovens rises above the gelatinization threshold more consistently, preventing premature crust hardening and allowing optimal starch swelling and gelatinization for superior crumb structure.

Oven Spring Maximization

Traditional ovens promote oven spring by creating dry heat that crisps the crust early, allowing rapid expansion of bread dough. Steam ovens enhance oven spring by injecting moisture, delaying crust formation, and enabling prolonged gas retention for a lighter, airier crumb.

Lactic Fermentation Retention

Traditional ovens often reduce lactic fermentation retention during bread baking due to dry heat, which can diminish the flavor complexity and texture developed by sourdough cultures. Steam ovens enhance lactic acid bacteria activity by maintaining optimal moisture levels, preserving fermentation benefits for chewier crumb and richer taste profiles.

Crust Sheen Enhancement

Traditional ovens create a thicker, crunchier crust by promoting Maillard reactions through dry heat, while steam ovens enhance crust sheen and elasticity by maintaining high humidity that slows moisture loss and allows sugar caramelization on the bread surface. Steam ovens produce a glossy, golden crust with a tender chew that is difficult to achieve in conventional dry heat baking.

Open Crumb Structure Yield

Traditional ovens rely on radiant heat to create crust, often resulting in denser crumb structures, while steam ovens introduce controlled moisture that enhances yeast activity, leading to an open crumb structure with larger, irregular air pockets. Steam ovens maintain optimal humidity levels during the baking process, improving dough expansion and crust formation essential for artisan bread with a light, airy texture.

Traditional oven vs Steam oven for bread baking. Infographic

cookingdiff.com

cookingdiff.com