A wire cooling rack offers an open grid design that promotes maximum air circulation, allowing baked goods to cool evenly and preventing sogginess. Stackable cooling grids save space in smaller kitchens by allowing multiple layers of baked goods to cool simultaneously without restricting airflow. Choosing between the two depends on your kitchen size and cooling needs, with wire racks ideal for larger batches and stackable grids perfect for compact storage.

Table of Comparison

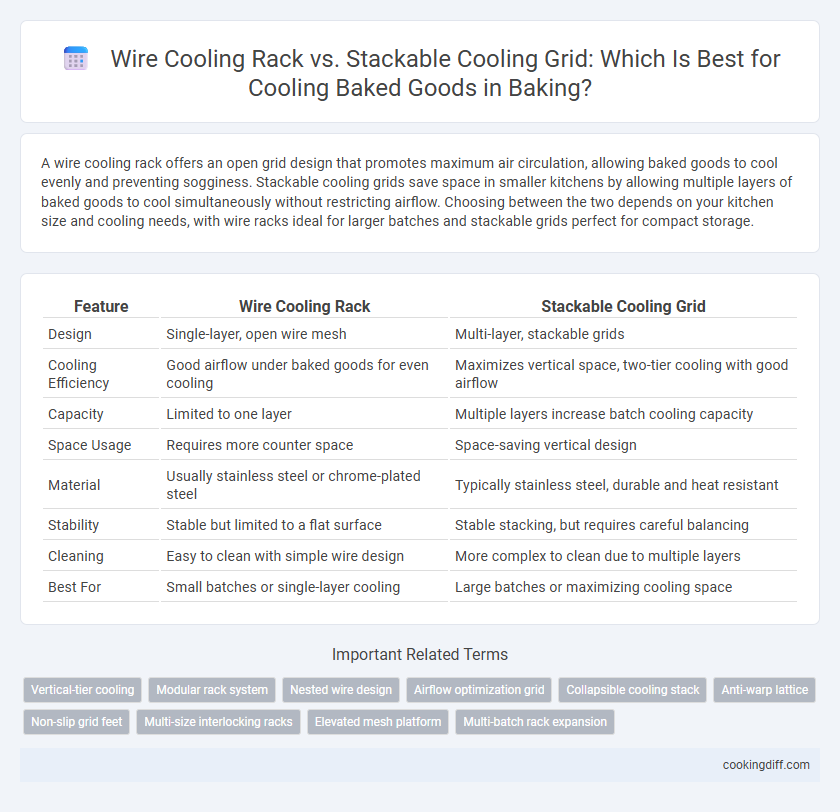

| Feature | Wire Cooling Rack | Stackable Cooling Grid |

|---|---|---|

| Design | Single-layer, open wire mesh | Multi-layer, stackable grids |

| Cooling Efficiency | Good airflow under baked goods for even cooling | Maximizes vertical space, two-tier cooling with good airflow |

| Capacity | Limited to one layer | Multiple layers increase batch cooling capacity |

| Space Usage | Requires more counter space | Space-saving vertical design |

| Material | Usually stainless steel or chrome-plated steel | Typically stainless steel, durable and heat resistant |

| Stability | Stable but limited to a flat surface | Stable stacking, but requires careful balancing |

| Cleaning | Easy to clean with simple wire design | More complex to clean due to multiple layers |

| Best For | Small batches or single-layer cooling | Large batches or maximizing cooling space |

Introduction to Cooling Baked Goods

Cooling baked goods properly is essential to preserve their texture and prevent sogginess. Choosing between a wire cooling rack and a stackable cooling grid can impact airflow and space efficiency during the cooling process.

- Wire Cooling Rack - Provides superior air circulation by elevating baked goods, allowing moisture to escape evenly.

- Stackable Cooling Grid - Maximizes kitchen space by enabling multiple layers of baked goods to cool simultaneously without crowding.

- Cooling Efficiency - Both tools enhance cooling but differ in airflow and capacity, influencing the final texture of cakes, cookies, and breads.

What Is a Wire Cooling Rack?

A wire cooling rack is a kitchen tool designed to elevate baked goods, allowing air to circulate freely for even cooling. It is typically made from stainless steel or chrome-plated metal, providing a sturdy surface for pastries, cakes, and cookies.

- Material - Made from durable stainless steel or chrome, preventing rust and ensuring longevity.

- Design - Features a grid or wire pattern that supports baked goods while promoting airflow on all sides.

- Functionality - Prevents sogginess by lifting food off flat surfaces, which aids in maintaining texture and freshness.

Wire cooling racks are essential for proper baking results, offering superior airflow compared to stackable cooling grids.

What Is a Stackable Cooling Grid?

| Stackable Cooling Grid Overview | A stackable cooling grid is a space-saving kitchen tool designed to cool multiple batches of baked goods simultaneously by stacking vertically, promoting optimal air circulation around each layer. |

| Material and Design | Typically made from stainless steel or non-stick coated metal, stackable grids feature interlocking edges ensuring stability and durability, ideal for cooling cookies, cakes, and bread evenly without moisture buildup. |

| Comparison to Wire Cooling Rack | Unlike a traditional wire cooling rack that sits flat and occupies more countertop space, stackable cooling grids maximize vertical storage, improving kitchen efficiency and allowing for faster cooling of larger batches. |

Space Efficiency: Wire Rack vs Stackable Grid

Wire cooling racks provide a single-layer surface that allows air to circulate around baked goods, but their limited footprint can consume significant counter space. Stackable cooling grids maximize vertical space by enabling multiple layers of baked items to cool simultaneously within the same horizontal area. This design enhances space efficiency, making stackable grids ideal for small kitchens or large batches requiring optimal air flow without overcrowding.

Air Circulation and Even Cooling Comparison

Wire cooling racks provide excellent air circulation by allowing air to flow freely beneath baked goods, promoting faster and more even cooling. Their open grid design minimizes moisture buildup, preventing sogginess in cookies, cakes, and breads.

Stackable cooling grids offer space-saving solutions by enabling multiple layers of cooling without compromising airflow around each layer. These grids maintain consistent temperature distribution, ensuring even cooling across all stacked baked goods.

Suitability for Different Baked Goods

Wire cooling racks are ideal for delicate baked goods such as cookies and cupcakes, allowing even air circulation to prevent sogginess. Stackable cooling grids are better suited for larger batches or denser items like bread and pastries, providing space-saving vertical cooling options.

Wire racks offer open grid designs that minimize moisture buildup, enhancing the texture of fragile treats. Stackable grids maximize kitchen efficiency by enabling multiple layers of baked goods to cool simultaneously. Choosing the right cooling tool depends on the type and quantity of baked items to ensure optimal freshness and texture.

Cleaning and Maintenance Considerations

Wire cooling racks typically feature a simple grid design that allows easy access for cleaning, making them less prone to trapping crumbs and residue. Stackable cooling grids, while space-efficient, often have multiple layers that may require more thorough scrubbing to prevent buildup between levels. Choosing between the two should consider the ease of maintenance and cleaning frequency based on baking volume and storage needs.

Durability and Material Differences

Wire cooling racks are typically made from stainless steel, offering excellent durability and resistance to rust and warping, which makes them suitable for frequent use in high-temperature environments. Stackable cooling grids often use coated metal or plastic materials, which may be less durable and prone to wear over time but provide space-saving benefits through their modular design.

Stainless steel wire racks maintain structural integrity longer and allow better airflow for evenly cooling baked goods, contributing to consistent baking results. In contrast, stackable grids, while convenient for storing multiple items simultaneously, can suffer from coating chipping or plastic brittleness, reducing their lifespan under heavy or repeated use.

Price and Value Comparison

Which option offers better value, a wire cooling rack or a stackable cooling grid? Wire cooling racks typically cost less, ranging from $10 to $20, providing a budget-friendly solution for basic cooling needs. Stackable cooling grids, priced between $20 and $40, offer enhanced capacity and efficient space-saving benefits, delivering greater long-term value for frequent bakers.

Related Important Terms

Vertical-tier cooling

Wire cooling racks with vertical-tier designs maximize airflow and space efficiency, allowing baked goods to cool evenly and quickly by stacking multiple layers without compromising ventilation. Stackable cooling grids offer modular flexibility, enabling bakers to customize cooling capacity while maintaining optimal air circulation between tiers for consistent texture and moisture retention.

Modular rack system

A modular wire cooling rack system offers customizable configurations for cooling multiple baked goods simultaneously while maximizing airflow to prevent sogginess. Stackable cooling grids enhance storage efficiency by allowing vertical layering without compromising the even cooling essential for quality texture and crust retention.

Nested wire design

Wire cooling racks with nested wire designs provide optimal airflow and support for delicate baked goods, preventing sogginess by allowing even cooling on all sides. Stackable cooling grids offer space-saving convenience but may restrict airflow between layers, potentially impacting the texture and crispness of baked items.

Airflow optimization grid

Wire cooling racks feature open grids that maximize airflow, ensuring even cooling and preventing sogginess in baked goods. Stackable cooling grids offer space-saving vertical layers but may restrict airflow compared to single-layer wire racks, potentially slowing the cooling process.

Collapsible cooling stack

Collapsible cooling stacks maximize kitchen space by allowing multiple layers of baked goods to cool simultaneously while easily folding for compact storage. Wire cooling racks generally provide single-layer cooling but lack the vertical stacking efficiency and collapsibility that streamline busy baking environments.

Anti-warp lattice

A wire cooling rack with an anti-warp lattice provides a durable, flat surface that maintains structural integrity under heat, preventing bending or warping when cooling baked goods. Stackable cooling grids may save space but often lack the reinforced lattice design, making them more prone to warping and uneven airflow during the cooling process.

Non-slip grid feet

Wire cooling racks with non-slip grid feet provide stable ventilation, preventing baked goods from sliding during cooling and ensuring even air circulation to maintain texture. Stackable cooling grids feature raised, non-slip feet as well, allowing secure layering without compromising airflow or stability in compact baking spaces.

Multi-size interlocking racks

Multi-size interlocking wire cooling racks provide versatile cooling solutions that optimize airflow beneath baked goods, preventing sogginess and ensuring even temperature distribution. Stackable cooling grids maximize kitchen space efficiency by allowing vertical storage of multiple trays, making them ideal for batch baking and rapid cooling without compromising structural stability.

Elevated mesh platform

Wire cooling racks provide an elevated mesh platform that promotes optimal air circulation around baked goods, preventing sogginess and ensuring even cooling. Stackable cooling grids maximize space efficiency by allowing multiple layers of elevation but may restrict airflow compared to a single wire rack's open mesh design.

Wire Cooling Rack vs Stackable Cooling Grid for cooling baked goods Infographic

cookingdiff.com

cookingdiff.com