Blanching involves briefly heating food in boiling water or steam to inactivate enzymes and improve texture, while vacuum infusion uses reduced pressure to rapidly infuse flavors into food by replacing air with a flavorful liquid. Blanching primarily alters the food's surface and structure, making it less effective for deep flavor penetration compared to vacuum infusion, which ensures more uniform and intense flavor distribution. Vacuum infusion offers precise control over flavor intensity, making it ideal for gourmet applications that require enhanced taste profiles without cooking the food.

Table of Comparison

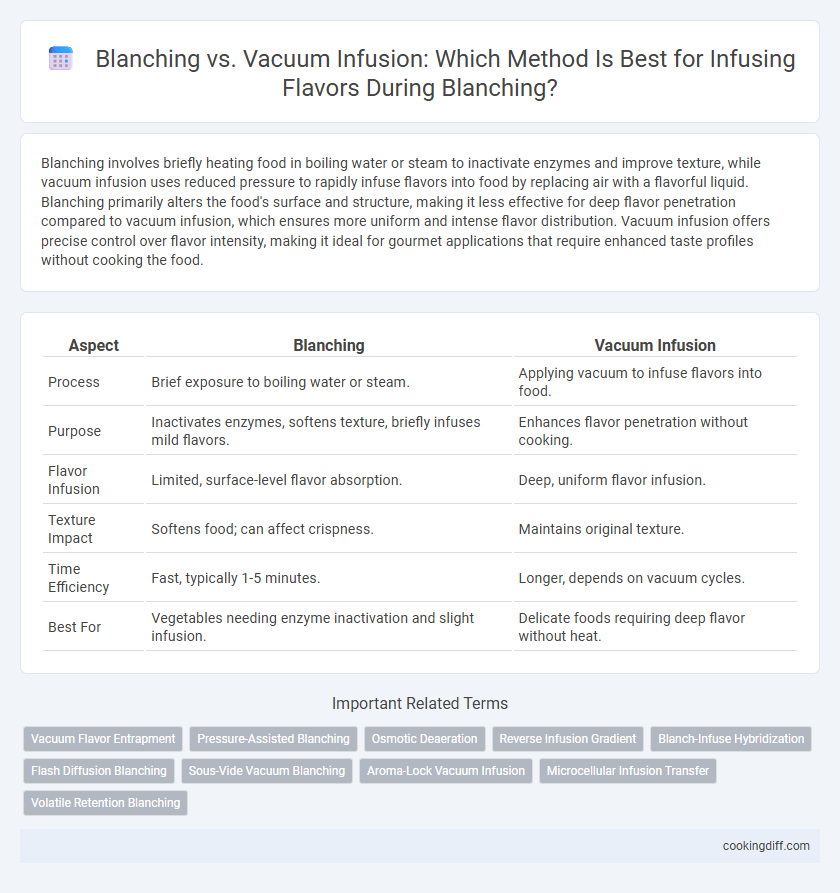

| Aspect | Blanching | Vacuum Infusion |

|---|---|---|

| Process | Brief exposure to boiling water or steam. | Applying vacuum to infuse flavors into food. |

| Purpose | Inactivates enzymes, softens texture, briefly infuses mild flavors. | Enhances flavor penetration without cooking. |

| Flavor Infusion | Limited, surface-level flavor absorption. | Deep, uniform flavor infusion. |

| Texture Impact | Softens food; can affect crispness. | Maintains original texture. |

| Time Efficiency | Fast, typically 1-5 minutes. | Longer, depends on vacuum cycles. |

| Best For | Vegetables needing enzyme inactivation and slight infusion. | Delicate foods requiring deep flavor without heat. |

Introduction to Flavor Infusion Techniques

| Blanching and vacuum infusion are key techniques in flavor infusion, each enhancing food differently. Blanching involves briefly boiling food to alter texture and flavor absorption, while vacuum infusion uses pressure to force flavors into porous foods rapidly and uniformly. Vacuum infusion offers superior penetration and intensity of flavor compared to the more surface-level effect of blanching. |

What is Blanching?

Blanching is a cooking process where food, usually vegetables or fruits, is briefly boiled in water or steamed and then rapidly cooled in ice water to halt the cooking process. This method softens the food and helps preserve its color, texture, and nutritional value.

Unlike vacuum infusion, which uses pressure changes to introduce flavors deep into food, blanching primarily prepares the food for further processing by inactivating enzymes that cause spoilage. It is commonly used before freezing or canning to maintain food quality. Blanching does not directly infuse flavors but enhances the effectiveness of subsequent flavoring techniques.

Understanding Vacuum Infusion

Vacuum infusion involves placing food in a vacuum chamber to remove air and allow flavors to penetrate more deeply than blanching. This method enhances flavor absorption by creating a pressure differential that drives liquids into the food's cellular structure.

- Vacuum pressure - Reduces internal air pockets in food, enabling faster and more uniform flavor infusion.

- Flavor retention - Preserves delicate flavors better than blanching, which uses heat that can degrade taste compounds.

- Texture impact - Maintains the food's structural integrity while introducing new flavors, unlike blanching which softens the texture.

Understanding vacuum infusion enables chefs to optimize flavor infusion while preserving food quality in ways blanching cannot achieve.

Key Differences: Blanching vs Vacuum Infusion

Blanching involves briefly boiling food to inactivate enzymes and preserve color, texture, and flavor, while vacuum infusion uses reduced pressure to rapidly infuse flavors or liquids into food items. Blanching primarily prepares food for storage or further cooking, whereas vacuum infusion enhances flavor penetration and uniformity without heat exposure.

Blanching is a thermal process that partially cooks food, affecting surface properties, while vacuum infusion maintains raw food structure by using negative pressure to draw liquids into tissues. The key difference lies in blanching's enzyme inactivation and partial cooking versus vacuum infusion's flavor enhancement without thermal impact.

Effectiveness in Flavor Transfer

Blanching effectively softens the surface of fruits and vegetables, allowing moderate flavor transfer during infusion processes. This method uses brief exposure to hot water or steam, which partially opens pores but may result in some nutrient loss.

Vacuum infusion creates a stronger and faster flavor transfer by removing air from the produce, enabling deeper penetration of flavors into the cellular structure. This technique preserves texture and nutrients better than blanching, making it more efficient for intense and uniform flavor infusion.

Impact on Ingredient Texture and Color

Blanching involves briefly exposing ingredients to boiling water or steam, which helps preserve vibrant color and crisp texture by deactivating enzymes that cause deterioration. Vacuum infusion uses reduced pressure to force flavors into ingredients, often resulting in softer textures and less intense color retention due to prolonged exposure to liquids. The choice between blanching and vacuum infusion significantly impacts the final product's appearance and mouthfeel, with blanching favoring texture firmness and color vibrancy.

Nutrient Retention Comparison

Blanching involves briefly boiling food to inactivate enzymes, which can cause some nutrient loss, particularly of water-soluble vitamins like vitamin C and B-complex. Vacuum infusion infuses flavors under reduced pressure and generally preserves more nutrients due to lower thermal exposure.

- Vitamin Preservation - Vacuum infusion retains higher levels of vitamin C and folate compared to blanching, which leaches these nutrients into boiling water.

- Enzyme Inactivation - Blanching effectively stops enzymatic activity but at the cost of moderate nutrient degradation from heat exposure.

- Mineral Retention - Vacuum infusion minimizes mineral loss by avoiding direct heat, whereas blanching can cause minerals to leach into blanching water.

Equipment and Preparation Requirements

Blanching requires basic equipment such as a pot of boiling water or steam source and ice water for rapid cooling, making it simple to set up in most kitchens. Vacuum infusion demands specialized vacuum chambers and pumps to create a low-pressure environment for efficient flavor absorption, resulting in higher initial equipment investment. Preparation for blanching is straightforward, while vacuum infusion involves meticulous sealing and monitoring to ensure optimal infusion and texture retention.

Best Applications for Each Method

Blanching is best suited for softening vegetables and stabilizing color before flavor infusion, while vacuum infusion excels at rapidly permeating dense foods with liquids. Each method optimizes flavor transfer depending on the food's texture and the desired infusion depth.

- Blanching - Ideal for leafy greens and vegetables that require texture softening and enzyme inactivation prior to flavor infusion.

- Vacuum Infusion - Best for fruits and meats where rapid and deep penetration of marinades or brines is essential.

- Combination Use - Blanching followed by vacuum infusion can enhance flavor absorption in firmer plant-based foods while preserving color and texture.

Related Important Terms

Vacuum Flavor Entrapment

Vacuum flavor entrapment during infusion enhances the penetration of aromatic compounds into food matrices by creating a low-pressure environment that opens pores and accelerates solvent absorption, resulting in more intense and uniform flavor profiles compared to traditional blanching. Unlike blanching, which uses heat to partially cook and sometimes leach flavors, vacuum infusion preserves delicate sensory qualities while maximizing flavor retention through controlled atmospheric pressure.

Pressure-Assisted Blanching

Pressure-assisted blanching enhances flavor infusion by rapidly heating food under pressure, preserving texture and nutrients while facilitating deeper penetration of marinades compared to conventional vacuum infusion methods. This technique accelerates enzyme inactivation and improves the absorption of flavors by creating a controlled high-pressure environment that boosts diffusion rates within the food matrix.

Osmotic Deaeration

Blanching effectively achieves osmotic deaeration by rapidly removing air from plant tissues, enhancing flavor infusion depth and uniformity compared to vacuum infusion, which relies on pressure differentials but may leave residual air pockets. The osmotic gradient created during blanching facilitates better absorption of flavor compounds, improving both texture and taste in infused products.

Reverse Infusion Gradient

Blanching induces a thermal shock that opens cellular walls, facilitating flavor infusion through a direct concentration gradient, whereas vacuum infusion uses pressure reduction to create a reverse infusion gradient by forcing fluids into intercellular spaces. The reverse infusion gradient in vacuum infusion allows for more uniform flavor penetration and retention compared to the surface-level permeation seen in blanching.

Blanch-Infuse Hybridization

Blanch-infusion hybridization combines the rapid heat inactivation of enzymes during blanching with the enhanced flavor penetration of vacuum infusion, resulting in improved texture retention and intensified taste profiles. This method optimizes nutrient preservation and infusion efficiency by leveraging thermal treatment to open cellular structures before vacuum-assisted flavor absorption.

Flash Diffusion Blanching

Flash Diffusion Blanching enhances flavor infusion by rapidly permeabilizing cell membranes, enabling deeper and faster absorption of solutions compared to Vacuum Infusion, which relies on pressure differentials. This method preserves texture and nutrients while improving the uniformity and intensity of flavor distribution in fruits and vegetables.

Sous-Vide Vacuum Blanching

Sous-vide vacuum blanching combines precise temperature control with vacuum infusion to enhance flavor penetration while preserving texture and nutrients more effectively than traditional blanching or vacuum infusion alone. This method ensures uniform heat distribution and reduced oxidation, resulting in superior flavor retention and improved food quality during infusing processes.

Aroma-Lock Vacuum Infusion

Aroma-Lock Vacuum Infusion outperforms traditional blanching by preserving delicate flavors and enhancing infusion efficiency through controlled pressure and vacuum cycles, which minimize nutrient loss and aroma volatilization. Unlike blanching's heat-induced flavor degradation, Aroma-Lock technology locks in volatile aromatic compounds, ensuring intensified taste and prolonged freshness in infused foods.

Microcellular Infusion Transfer

Blanching uses brief heat treatment to inactivate enzymes and stabilize food texture while minimally affecting flavor infusion through limited microcellular infusion transfer. Vacuum infusion enhances flavor penetration by creating pressure differentials that improve microcellular infusion transfer, allowing deeper and more uniform distribution of flavors within food matrices.

Blanching vs Vacuum infusion for infusing flavors. Infographic

cookingdiff.com

cookingdiff.com