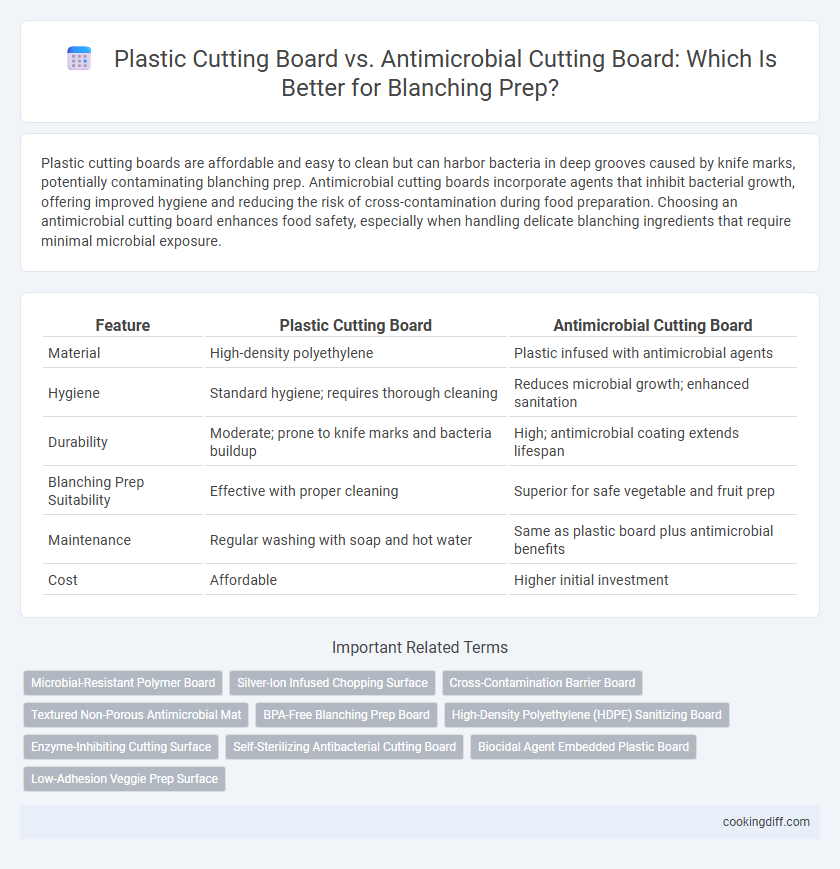

Plastic cutting boards are affordable and easy to clean but can harbor bacteria in deep grooves caused by knife marks, potentially contaminating blanching prep. Antimicrobial cutting boards incorporate agents that inhibit bacterial growth, offering improved hygiene and reducing the risk of cross-contamination during food preparation. Choosing an antimicrobial cutting board enhances food safety, especially when handling delicate blanching ingredients that require minimal microbial exposure.

Table of Comparison

| Feature | Plastic Cutting Board | Antimicrobial Cutting Board |

|---|---|---|

| Material | High-density polyethylene | Plastic infused with antimicrobial agents |

| Hygiene | Standard hygiene; requires thorough cleaning | Reduces microbial growth; enhanced sanitation |

| Durability | Moderate; prone to knife marks and bacteria buildup | High; antimicrobial coating extends lifespan |

| Blanching Prep Suitability | Effective with proper cleaning | Superior for safe vegetable and fruit prep |

| Maintenance | Regular washing with soap and hot water | Same as plastic board plus antimicrobial benefits |

| Cost | Affordable | Higher initial investment |

Introduction to Cutting Boards for Blanching Preparation

Plastic cutting boards are a popular choice for blanching preparation due to their non-porous surface, which resists moisture absorption and minimizes bacterial growth. Their durability and ease of cleaning with hot, soapy water make them ideal for repeated blanching tasks.

Antimicrobial cutting boards incorporate built-in agents to inhibit microbial growth, offering an extra layer of hygiene during food prep, especially when handling vegetables destined for blanching. These boards often feature materials like silver ions or copper, which reduce the risk of cross-contamination and maintain food safety standards.

Understanding Plastic Cutting Boards

Plastic cutting boards offer a non-porous surface that resists moisture absorption, reducing bacterial growth during blanching preparation. Their smooth texture allows for easy cleaning and sanitizing, making them a practical choice for handling vegetables before blanching. While antimicrobial cutting boards inhibit microbial activity, understanding the hygienic properties of plastic boards ensures safe and efficient food prep.

What Are Antimicrobial Cutting Boards?

| Antimicrobial cutting boards are designed with embedded agents that inhibit the growth of bacteria and fungi, making them ideal for blanching prep where food safety is critical. |

| Unlike plastic cutting boards, antimicrobial versions reduce cross-contamination risks by continuously suppressing microbial activity on their surfaces. |

| These boards are especially beneficial in blanching preparation as they maintain hygiene standards and extend the board's usability without frequent chemical sanitization. |

Safety and Hygiene: Plastic vs Antimicrobial Boards

Plastic cutting boards are non-porous, making them resistant to moisture and easy to sanitize, which is crucial for blanching preparation where food safety is a priority. However, they can develop deep knife grooves that harbor bacteria if not properly cleaned.

Antimicrobial cutting boards contain agents that inhibit bacterial growth, reducing contamination risks during repeated use in blanching prep. These boards offer enhanced hygiene by actively preventing microbial buildup, supporting safer food handling practices.

Durability Comparison: Plastic vs Antimicrobial

Plastic cutting boards are generally durable but can develop deep grooves from frequent knife use, which may harbor bacteria during blanching prep. Antimicrobial cutting boards feature built-in agents that inhibit microbial growth, enhancing longevity and hygiene under intensive use.

- Plastic cutting boards tend to wear faster - knife marks accumulate over time, increasing the risk of contamination.

- Antimicrobial boards resist bacterial buildup - prolonging usable surface life and reducing the need for replacement.

- Durability differences impact blanching safety - making antimicrobial boards more suitable for repeated vegetable prep.

Ease of Cleaning and Maintenance

Plastic cutting boards are non-porous and dishwasher-safe, making them easy to clean and sanitize after blanching prep. Antimicrobial cutting boards inhibit bacterial growth but may require hand washing to maintain their protective coating and effectiveness.

- Plastic cutting boards are dishwasher-safe - This allows thorough cleaning at high temperatures, reducing bacterial contamination risks.

- Antimicrobial cutting boards inhibit bacterial growth - They reduce surface bacteria but often need gentle hand washing to preserve their antimicrobial properties.

- Plastic boards tend to show knife marks - These grooves can harbor bacteria if not properly cleaned, requiring regular inspection and replacement.

Choosing between these boards depends on prioritizing ease of cleaning or built-in bacterial resistance for blanching prep.

Impact on Food Quality During Blanching Prep

Plastic cutting boards provide a non-porous surface that minimizes bacterial contamination during blanching preparation, helping maintain food safety and quality. Antimicrobial cutting boards actively reduce microbial presence, further protecting food from spoilage and preserving its freshness before blanching.

- Plastic cutting boards - offer ease of cleaning and resistance to knife marks, reducing microbial buildup that can affect food quality.

- Antimicrobial cutting boards - inhibit growth of bacteria on the surface, lowering the risk of cross-contamination during pre-blanching prep.

- Impact on food quality - cutting board choice directly influences microbial levels, affecting texture, flavor, and safety of blanched food.

Cost Analysis: Which Cutting Board Is More Economical?

Plastic cutting boards typically cost less upfront compared to antimicrobial cutting boards, making them a budget-friendly option for blanching prep. However, antimicrobial boards often reduce the need for frequent replacements due to their durability and resistance to bacteria growth. Considering long-term use, antimicrobial cutting boards may offer better cost efficiency by minimizing maintenance and health-related expenses.

Environmental Considerations

Plastic cutting boards, often made from non-biodegradable materials, contribute to long-term environmental waste when discarded. Antimicrobial cutting boards, typically infused with agents like silver ions, may raise concerns about chemical leaching and environmental toxicity during disposal.

Choosing antimicrobial cutting boards can reduce bacterial contamination during blanching prep, potentially decreasing the need for frequent replacements and lowering overall plastic waste. However, the production and disposal processes of antimicrobial materials might involve environmental trade-offs, including resource consumption and pollution. Evaluating the lifecycle impact of both types helps in making a more sustainable decision for blanching preparation tools.

Related Important Terms

Microbial-Resistant Polymer Board

Microbial-resistant polymer cutting boards offer superior hygiene for blanching prep by significantly reducing bacterial contamination compared to traditional plastic cutting boards. Their engineered surface inhibits microbial growth, ensuring safer food handling and minimizing cross-contamination risks during vegetable and fruit preparation.

Silver-Ion Infused Chopping Surface

Silver-ion infused antimicrobial cutting boards inhibit bacterial growth more effectively than traditional plastic cutting boards, enhancing food safety during blanching prep. Their durable, non-porous surface resists surface damage and microbial contamination, reducing the risk of cross-contamination and maintaining hygiene standards.

Cross-Contamination Barrier Board

Plastic cutting boards provide a smooth, non-porous surface that resists absorption of moisture and bacteria, making them effective for blanching prep by minimizing bacterial transfer. Antimicrobial cutting boards incorporate agents that inhibit microbial growth, enhancing their function as a cross-contamination barrier board during blanching to maintain higher hygiene standards.

Textured Non-Porous Antimicrobial Mat

Textured non-porous antimicrobial mats offer superior hygiene and durability compared to plastic cutting boards for blanching preparation, minimizing bacterial growth while resisting surface knife scars. Their antimicrobial properties and easy-to-clean texture reduce cross-contamination risks and maintain food safety standards critical in blanching processes.

BPA-Free Blanching Prep Board

A BPA-free plastic cutting board offers a safe, non-toxic surface for blanching prep by preventing chemical leaching during food contact, while an antimicrobial cutting board incorporates embedded agents to inhibit bacterial growth. Selecting a BPA-free blanching prep board ensures both food safety and durability, reducing the risk of contamination in high-moisture environments typical of blanching processes.

High-Density Polyethylene (HDPE) Sanitizing Board

High-Density Polyethylene (HDPE) cutting boards are favored for blanching prep due to their non-porous surface, which resists microbial penetration and facilitates effective sanitizing, reducing cross-contamination risks. Compared to antimicrobial cutting boards, HDPE boards offer durability and compatibility with rigorous cleaning protocols, ensuring consistent hygiene standards during intense blanching processes.

Enzyme-Inhibiting Cutting Surface

Plastic cutting boards offer a non-porous surface that resists moisture absorption, reducing bacterial growth during blanching prep; however, antimicrobial cutting boards provide an enzyme-inhibiting surface that actively disrupts enzyme activity responsible for food spoilage and discoloration, enhancing freshness. Selecting an enzyme-inhibiting cutting surface optimizes blanching efficiency by minimizing enzymatic degradation, preserving color and texture in vegetables.

Self-Sterilizing Antibacterial Cutting Board

Self-sterilizing antibacterial cutting boards, embedded with copper or silver ions, actively inhibit bacterial growth, making them superior to traditional plastic cutting boards in maintaining hygiene during blanching prep. Their continuous antimicrobial action reduces cross-contamination risks and ensures safer food handling without frequent chemical sanitizing.

Biocidal Agent Embedded Plastic Board

Plastic cutting boards embedded with biocidal agents offer enhanced antimicrobial protection during blanching prep by inhibiting bacterial growth on the surface, reducing cross-contamination risks. These boards maintain durability and hygiene more effectively than standard plastic cutting boards, ensuring safer food handling in high-moisture blanching environments.

Plastic cutting board vs antimicrobial cutting board for blanching prep. Infographic

cookingdiff.com

cookingdiff.com