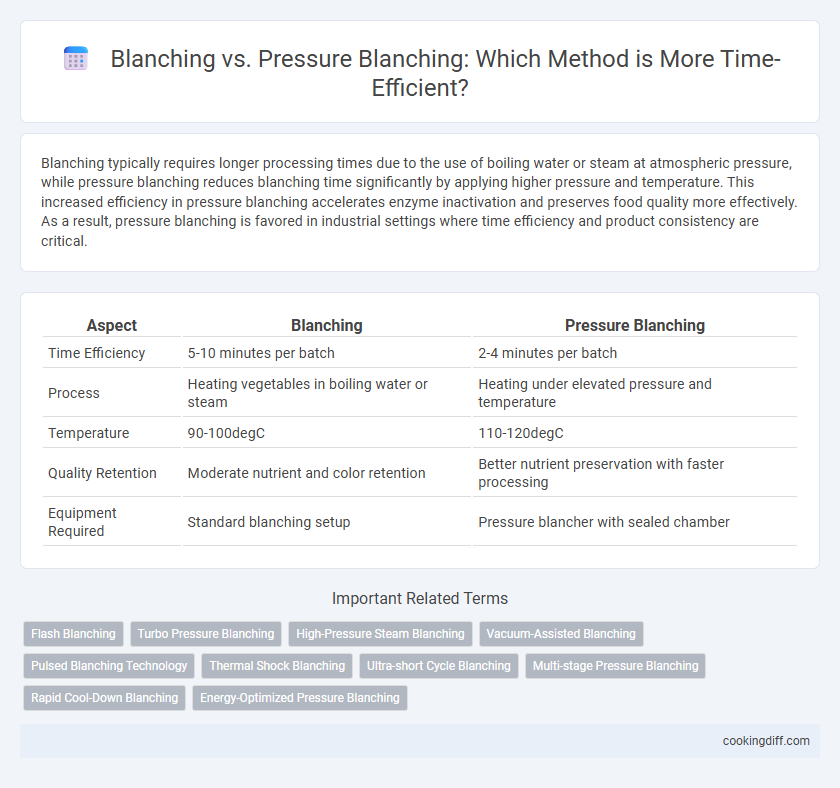

Blanching typically requires longer processing times due to the use of boiling water or steam at atmospheric pressure, while pressure blanching reduces blanching time significantly by applying higher pressure and temperature. This increased efficiency in pressure blanching accelerates enzyme inactivation and preserves food quality more effectively. As a result, pressure blanching is favored in industrial settings where time efficiency and product consistency are critical.

Table of Comparison

| Aspect | Blanching | Pressure Blanching |

|---|---|---|

| Time Efficiency | 5-10 minutes per batch | 2-4 minutes per batch |

| Process | Heating vegetables in boiling water or steam | Heating under elevated pressure and temperature |

| Temperature | 90-100degC | 110-120degC |

| Quality Retention | Moderate nutrient and color retention | Better nutrient preservation with faster processing |

| Equipment Required | Standard blanching setup | Pressure blancher with sealed chamber |

Introduction to Blanching and Pressure Blanching

Blanching is a heat treatment process where vegetables or fruits are briefly boiled or steamed to inactivate enzymes and preserve quality. Pressure blanching uses high pressure steam, allowing faster heat penetration and shorter processing times compared to conventional blanching. This efficiency reduces nutrient loss and energy consumption in food processing operations.

Defining Traditional Blanching Methods

Traditional blanching methods involve briefly boiling or steaming vegetables to inactivate enzymes and preserve color, texture, and nutritional value. This process typically requires immersion in hot water or exposure to steam for several minutes, followed by rapid cooling in ice water. Compared to pressure blanching, traditional blanching is generally less time-efficient due to longer treatment and cooling times.

What is Pressure Blanching?

Pressure blanching uses steam under higher pressure to quickly heat vegetables, significantly reducing blanching time compared to traditional methods. This technique preserves texture and nutrients more effectively by minimizing exposure to heat and water.

- Rapid heat transfer - Pressure blanching accelerates the heating process by increasing steam pressure and temperature.

- Time savings - Typically reduces blanching time by 30% to 50% compared to conventional blanching.

- Nutrient retention - Limits leaching and degradation of vitamins by shortening thermal exposure.

Time Comparison: Blanching vs Pressure Blanching

| Blanching Method | Average Processing Time |

|---|---|

| Traditional Blanching | 3 to 5 minutes per batch |

| Pressure Blanching | 1 to 2 minutes per batch |

| Time Efficiency | Pressure blanching reduces blanching time by up to 60% compared to traditional methods |

Equipment Requirements and Setup Speed

How do equipment requirements and setup speed compare between blanching and pressure blanching for time efficiency? Traditional blanching requires simple equipment with minimal setup, allowing quick start times but longer processing durations. Pressure blanching involves specialized, high-pressure vessels that demand more complex setup but significantly reduce overall blanching time.

Impact on Food Quality and Nutrient Retention

Blanching typically involves boiling vegetables briefly, preserving color and texture but sometimes causing partial nutrient loss, especially water-soluble vitamins. Pressure blanching uses higher temperatures and pressure to reduce blanching time significantly while maintaining better enzyme inactivation.

Pressure blanching enhances nutrient retention by minimizing exposure to heat and oxygen, thus better preserving antioxidants and vitamins like vitamin C. This method improves food quality through faster processing, resulting in crisper texture and more vibrant color compared to conventional blanching.

Energy Consumption Considerations

Blanching typically involves lower energy consumption due to its shorter processing times and moderate temperature requirements. Pressure blanching, by operating at higher temperatures and pressures, consumes more energy but often reduces overall blanching time, leading to potential efficiency gains in large-scale operations.

Energy consumption considerations are critical when choosing between blanching and pressure blanching methods. While pressure blanching uses more energy per unit of time, its faster processing reduces total energy use for high-volume throughput. This makes pressure blanching more energy-efficient for industrial applications, despite higher instantaneous energy demands.

Scalability for Home and Industrial Kitchens

Blanching typically requires longer processing times, making it suitable for small-scale home kitchens where batch size is limited. Pressure blanching significantly reduces blanching time, enhancing scalability for industrial kitchens managing large volumes efficiently.

- Home Kitchen Blanching - Conventional blanching uses simple equipment ideal for occasional, small-batch food preparation.

- Industrial Kitchen Efficiency - Pressure blanching accelerates heat penetration, enabling high throughput without compromising quality.

- Scalability Difference - Pressure blanching systems are designed to handle large quantities, optimizing operational workflow in commercial settings.

Pressure blanching offers superior time efficiency and scalability for industrial applications compared to traditional blanching methods.

Practical Use Cases for Time Efficiency

Traditional blanching typically requires longer times due to lower temperatures and open boiling, making it less time-efficient for high-volume food processing. Pressure blanching uses higher temperatures and steam pressure to dramatically reduce blanching times, optimizing productivity in industrial kitchens and food manufacturing.

- Traditional blanching duration - Often ranges from 3 to 10 minutes, depending on the vegetable type and batch size.

- Pressure blanching efficiency - Reduces blanching time by up to 50% through faster heat penetration under pressure.

- Industrial application - Pressure blanching is preferred in commercial food processing to enhance throughput and maintain product quality.

Related Important Terms

Flash Blanching

Flash blanching significantly reduces processing time compared to traditional and pressure blanching methods by rapidly heating vegetables in near-boiling water or steam for a brief period, typically 15-30 seconds, which preserves color, texture, and nutritional value more effectively. Pressure blanching, while effective for microbial inactivation, requires longer exposure times and higher energy input, making flash blanching a more time-efficient choice for commercial vegetable processing.

Turbo Pressure Blanching

Turbo Pressure Blanching significantly reduces processing time compared to traditional blanching methods by utilizing high pressure and temperature to rapidly inactivate enzymes and preserve food quality. This method enhances time efficiency in industrial applications by minimizing blanching duration while maintaining nutritional and sensory attributes.

High-Pressure Steam Blanching

High-Pressure Steam Blanching significantly reduces processing time compared to traditional blanching by utilizing elevated steam pressure to rapidly raise the temperature, ensuring efficient enzyme inactivation and improved food quality. This method enhances time efficiency by shortening blanching duration while maintaining nutritional value and texture in fruits and vegetables.

Vacuum-Assisted Blanching

Vacuum-Assisted Blanching reduces blanching time significantly compared to traditional and pressure blanching by lowering the boiling point of water, enabling faster heat penetration in vegetables. This method enhances time efficiency through superior heat transfer and reduced nutrient loss, outperforming conventional and pressure blanching techniques in industrial food processing.

Pulsed Blanching Technology

Pulsed Blanching Technology significantly reduces processing time compared to traditional blanching and pressure blanching by delivering rapid, controlled bursts of heat that enhance heat transfer efficiency. This innovative method minimizes nutrient loss and preserves texture while enabling faster throughput in industrial food processing.

Thermal Shock Blanching

Thermal shock blanching drastically reduces processing time compared to traditional blanching by rapidly heating and cooling produce, minimizing nutrient loss and texture degradation. Pressure blanching accelerates heat penetration through increased pressure but often requires longer cycle times than the instantaneous temperature change achieved in thermal shock blanching, enhancing time efficiency in industrial applications.

Ultra-short Cycle Blanching

Ultra-short Cycle Blanching significantly reduces processing time compared to traditional pressure blanching by utilizing rapid heating and cooling phases, often completing the blanching process in under a minute. This method enhances time efficiency while preserving product quality and nutrient retention, making it ideal for high-throughput food processing operations.

Multi-stage Pressure Blanching

Multi-stage pressure blanching significantly reduces processing time by combining controlled pressure and temperature phases, enhancing heat transfer efficiency compared to conventional blanching. This method optimizes enzyme inactivation and texture retention while minimizing nutrient loss in vegetables, making it a time-efficient alternative for commercial food processing.

Rapid Cool-Down Blanching

Rapid Cool-Down Blanching significantly reduces processing time compared to traditional Pressure Blanching by quickly halting enzymatic activity through immediate cooling. This method enhances time efficiency while preserving texture and nutritional quality in vegetables.

Blanching vs Pressure Blanching for time efficiency Infographic

cookingdiff.com

cookingdiff.com