Blanching helps preserve the color and texture of vegetables by briefly boiling or steaming them, but it can lead to nutrient loss, particularly water-soluble vitamins. Vacuum-blanching, performed under reduced pressure, minimizes exposure to oxygen and heat, resulting in better retention of vitamins and antioxidants. This method is especially effective for maintaining the nutritional quality and freshness of delicate produce during food processing.

Table of Comparison

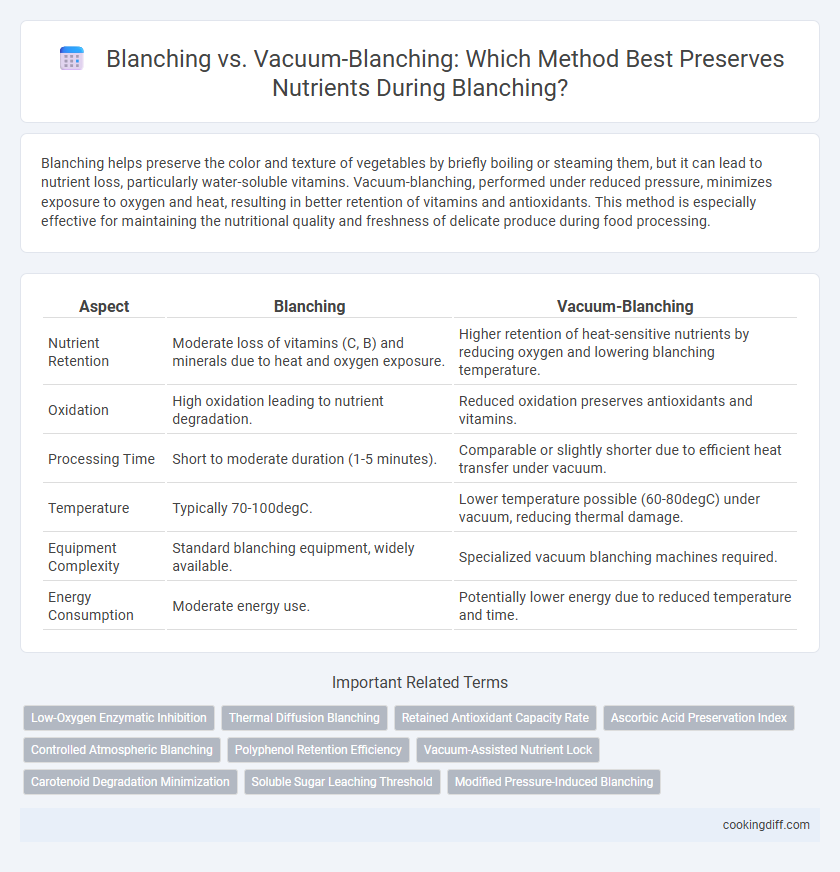

| Aspect | Blanching | Vacuum-Blanching |

|---|---|---|

| Nutrient Retention | Moderate loss of vitamins (C, B) and minerals due to heat and oxygen exposure. | Higher retention of heat-sensitive nutrients by reducing oxygen and lowering blanching temperature. |

| Oxidation | High oxidation leading to nutrient degradation. | Reduced oxidation preserves antioxidants and vitamins. |

| Processing Time | Short to moderate duration (1-5 minutes). | Comparable or slightly shorter due to efficient heat transfer under vacuum. |

| Temperature | Typically 70-100degC. | Lower temperature possible (60-80degC) under vacuum, reducing thermal damage. |

| Equipment Complexity | Standard blanching equipment, widely available. | Specialized vacuum blanching machines required. |

| Energy Consumption | Moderate energy use. | Potentially lower energy due to reduced temperature and time. |

Introduction to Blanching Techniques

Blanching is a thermal process used to inactivate enzymes and preserve the color, texture, and nutritional quality of vegetables. Vacuum-blanching introduces a reduced-pressure environment, potentially enhancing nutrient retention by minimizing oxidation and preserving heat-sensitive vitamins.

- Traditional Blanching - Involves immersing vegetables in hot water or steam at atmospheric pressure to inhibit enzymatic activity.

- Vacuum-Blanching - Utilizes a low-pressure chamber to blanch food, reducing oxygen exposure and preserving delicate nutrients.

- Nutrient Retention Comparison - Vacuum-blanching typically results in higher retention of water-soluble vitamins like vitamin C, compared to conventional blanching.

What Is Traditional Blanching?

Traditional blanching involves briefly boiling or steaming vegetables to inactivate enzymes that cause spoilage and maintain color and texture. This process typically lasts from 1 to 5 minutes depending on the vegetable type and size.

Vacuum-blanching, unlike traditional blanching, removes air by creating a vacuum environment before heating, which helps in better nutrient retention and reduces oxidation. Studies show vacuum-blanching preserves higher levels of vitamin C and antioxidants compared to conventional blanching methods.

Vacuum-Blanching Explained

Vacuum-blanching uses reduced atmospheric pressure to lower the boiling point of water, allowing blanching at lower temperatures and shorter times compared to conventional blanching. This method significantly improves the retention of heat-sensitive nutrients such as vitamin C and folate in vegetables.

The vacuum environment minimizes oxidation and nutrient leaching, preserving color, texture, and flavor integrity while maintaining higher antioxidant levels. Studies show vacuum-blanched produce retains up to 30% more nutrients than traditionally blanched counterparts, enhancing overall food quality.

Scientific Principles Behind Blanching Methods

Blanching involves brief exposure to boiling water or steam to inactivate enzymes and preserve color, texture, and nutrients in vegetables. Vacuum blanching reduces oxidation and nutrient loss by lowering the boiling point of water through reduced pressure, enhancing nutrient retention compared to traditional methods. Scientific studies demonstrate that vacuum blanching maintains higher levels of vitamin C and antioxidants due to minimized thermal degradation and oxygen exposure.

Nutrient Retention: Key Factors in Blanching

Blanching preserves nutrients primarily by inactivating enzymes that cause degradation, but traditional methods often result in significant losses of water-soluble vitamins such as vitamin C and folate. Vacuum-blanching reduces exposure to oxygen and high temperatures, enhancing the retention of sensitive nutrients.

Key factors influencing nutrient retention during blanching include temperature, time, and oxygen levels. Vacuum-blanching operates under reduced pressure, which lowers the boiling point of water and minimizes thermal damage to vitamins and antioxidants. Studies demonstrate that vacuum-blanching can retain up to 30% more vitamin C compared to conventional blanching techniques, making it a superior method for preserving nutritional quality.

Comparative Studies: Nutrient Loss in Blanching vs Vacuum-Blanching

Comparative studies on nutrient loss indicate vacuum-blanching preserves higher levels of vitamin C and chlorophyll compared to traditional blanching. Vacuum-blanching minimizes oxidative degradation and leaching of water-soluble nutrients by reducing exposure to oxygen and water during processing. Research highlights that vacuum-blanched vegetables retain up to 30% more antioxidants and essential vitamins, enhancing overall nutritional quality.

Vitamins and Minerals: Preservation Differences

Vacuum-blanching better preserves vitamins and minerals compared to traditional blanching due to reduced oxygen exposure and lower temperatures. This method minimizes nutrient degradation, especially for vitamin C and B-complex vitamins, which are sensitive to heat and oxidation.

- Vitamin Retention - Vacuum-blanching significantly reduces vitamin C loss by limiting oxidative reactions during processing.

- Mineral Stability - Minerals such as potassium and magnesium remain more stable since vacuum-blanching reduces leaching caused by high-temperature water.

- Heat Sensitivity - Lower blanching temperatures in vacuum conditions help maintain heat-sensitive nutrients compared to conventional methods.

Impact on Color, Texture, and Flavor

| Blanching Method | Impact on Color | Impact on Texture | Impact on Flavor |

|---|---|---|---|

| Traditional Blanching | May cause slight color loss due to oxidation and heat exposure | Softens texture, sometimes leading to overcooking if not timed properly | Can result in mild flavor loss from leaching of soluble compounds |

| Vacuum-Blanching | Better preserves vibrant color by reducing oxygen contact and oxidation | Maintains firmer texture by minimizing thermal degradation and moisture loss | Retains more natural flavor by limiting flavor compound evaporation and leaching |

Practical Considerations for Home and Industry

How do blanching and vacuum-blanching compare in nutrient retention for home and industrial applications? Traditional blanching is effective for enzyme inactivation but can cause nutrient loss due to exposure to high temperature and oxygen. Vacuum-blanching reduces oxidation and preserves vitamins like vitamin C and carotenoids more efficiently, making it favorable for nutrient-sensitive processing in both domestic and commercial settings.

Related Important Terms

Low-Oxygen Enzymatic Inhibition

Vacuum-blanching significantly enhances nutrient retention by creating a low-oxygen environment that inhibits oxidative enzymatic activity more effectively than traditional blanching. This reduction in oxygen exposure limits the degradation of sensitive vitamins such as vitamin C and preserves the antioxidant capacity of vegetables during processing.

Thermal Diffusion Blanching

Thermal Diffusion Blanching enhances nutrient retention by minimizing heat exposure and reducing leaching compared to conventional blanching methods, preserving vitamins and antioxidants more effectively. Vacuum-blanching further improves this process by lowering the boiling point of water, enabling faster heat penetration and better maintenance of heat-sensitive nutrients in fruits and vegetables.

Retained Antioxidant Capacity Rate

Vacuum-blanching preserves higher antioxidant capacity rates compared to traditional blanching by minimizing oxygen exposure and thermal degradation. Studies show vacuum-blanching can retain up to 90% of antioxidant compounds, enhancing nutrient retention in processed vegetables.

Ascorbic Acid Preservation Index

Vacuum-blanching significantly improves the Ascorbic Acid Preservation Index by minimizing oxygen exposure and thermal degradation compared to conventional blanching methods. Studies show vacuum-blanched vegetables retain up to 30% more vitamin C, enhancing overall nutrient retention and product quality.

Controlled Atmospheric Blanching

Controlled Atmospheric Blanching (CAB) significantly enhances nutrient retention compared to traditional vacuum-blanching by regulating oxygen levels and temperature to minimize oxidative degradation of vitamins and phytochemicals. This method preserves higher levels of ascorbic acid, carotenoids, and polyphenols in vegetables, ensuring superior quality and extended shelf life.

Polyphenol Retention Efficiency

Vacuum-blanching significantly enhances polyphenol retention compared to conventional blanching by reducing oxidation through low oxygen exposure and lower temperatures. Studies show vacuum-blanched vegetables retain up to 30-40% more polyphenols, preserving antioxidant capacity and improving nutritional quality.

Vacuum-Assisted Nutrient Lock

Vacuum-blanching enhances nutrient retention by minimizing oxidation and thermal degradation through reduced oxygen exposure and lower blanching temperatures. This vacuum-assisted nutrient lock preserves vitamins, antioxidants, and flavor compounds more effectively than traditional blanching methods.

Carotenoid Degradation Minimization

Vacuum-blanching significantly reduces carotenoid degradation by limiting oxygen exposure and thermal oxidation compared to traditional blanching methods. This preservation technique enhances nutrient retention in vegetables, maintaining higher levels of carotenoids essential for health benefits.

Soluble Sugar Leaching Threshold

Blanching leads to significant soluble sugar leaching due to high-temperature water exposure, whereas vacuum-blanching reduces this leaching by lowering boiling points and limiting sugar diffusion. Studies show vacuum-blanching can retain up to 30% more soluble sugars by minimizing thermal degradation and solute loss during processing.

Blanching vs Vacuum-blanching for nutrient retention. Infographic

cookingdiff.com

cookingdiff.com