Blanching effectively preserves the color of vegetables by inactivating enzymes responsible for browning, yet it may cause some loss of vibrancy due to heat exposure. Cryo-blanching utilizes extremely low temperatures to halt enzymatic activity, maintaining brighter and more natural colors compared to traditional blanching methods. This cold-based approach reduces pigment degradation and enhances overall visual appeal in processed produce.

Table of Comparison

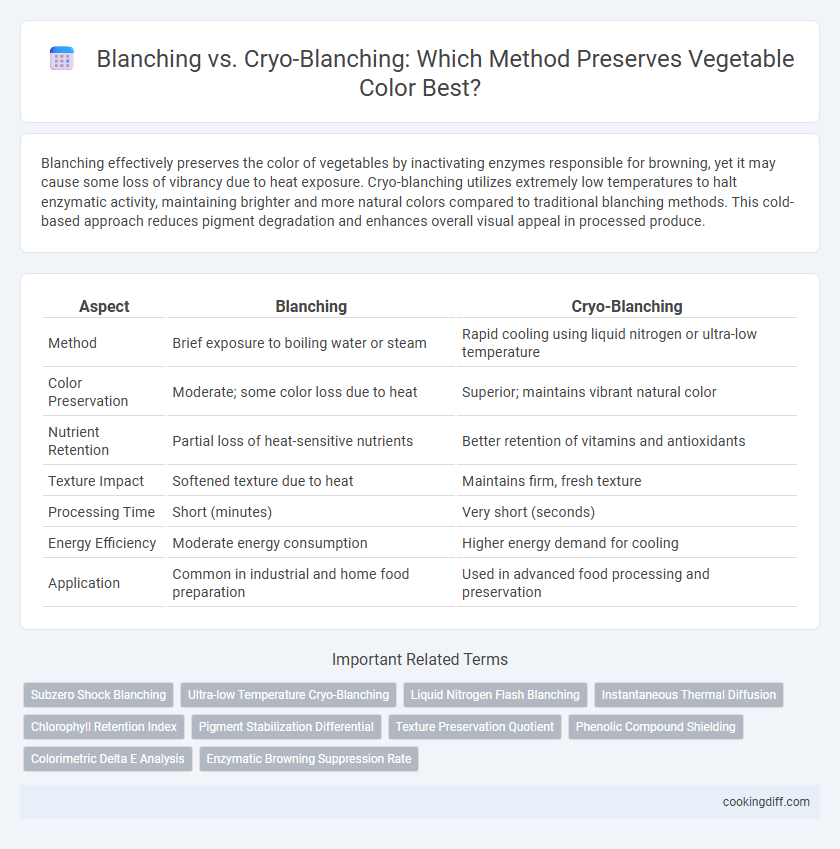

| Aspect | Blanching | Cryo-Blanching |

|---|---|---|

| Method | Brief exposure to boiling water or steam | Rapid cooling using liquid nitrogen or ultra-low temperature |

| Color Preservation | Moderate; some color loss due to heat | Superior; maintains vibrant natural color |

| Nutrient Retention | Partial loss of heat-sensitive nutrients | Better retention of vitamins and antioxidants |

| Texture Impact | Softened texture due to heat | Maintains firm, fresh texture |

| Processing Time | Short (minutes) | Very short (seconds) |

| Energy Efficiency | Moderate energy consumption | Higher energy demand for cooling |

| Application | Common in industrial and home food preparation | Used in advanced food processing and preservation |

Understanding Blanching: Traditional Techniques Explained

How do traditional blanching and cryo-blanching compare in preserving the color of vegetables? Traditional blanching uses hot water or steam to inactivate enzymes, often causing some color loss due to heat exposure. Cryo-blanching applies ultra-low temperatures using liquid nitrogen or carbon dioxide, reducing enzymatic browning and better maintaining vibrant colors in vegetables.

What is Cryo-Blanching? A Modern Approach

Cryo-blanching is a modern food processing technique that uses ultra-low temperatures, typically with liquid nitrogen or carbon dioxide, to rapidly blanch vegetables and fruits. This method minimizes thermal damage, preserving vibrant colors better than traditional hot water or steam blanching.

By exposing produce to cryogenic temperatures, enzymatic activity is quickly halted, which helps maintain chlorophyll and other natural pigments responsible for the fresh appearance. Unlike conventional blanching, cryo-blanching reduces nutrient loss and does not cause texture softening. This innovative approach offers enhanced visual appeal and extended shelf life for fresh-cut products.

Importance of Color Preservation in Cooking

Color preservation in cooking significantly impacts the visual appeal and perceived freshness of food, influencing consumer preference and satisfaction. Blanching and cryo-blanching techniques differ in their effectiveness at maintaining vibrant colors during food processing.

- Blanching - Uses hot water or steam to inactivate enzymes, but can cause some color loss due to heat exposure.

- Cryo-blanching - Utilizes ultra-low temperatures to better retain natural pigments by minimizing thermal degradation.

- Color preservation importance - Enhances nutritional quality perception and market value of produce in processed foods.

The Science Behind Color Loss in Vegetables

Color loss in vegetables during blanching primarily results from the degradation of chlorophyll and the oxidation of carotenoids caused by heat exposure. Conventional blanching at high temperatures disrupts cell membranes, accelerating pigment leaching and enzymatic browning.

Cryo-blanching employs ultra-low temperatures, freezing the vegetable surface to better preserve pigment integrity by limiting enzyme activity and pigment oxidation. This method maintains vibrancy in chlorophyll-rich vegetables by minimizing thermal damage and pigment breakdown.

Blanching vs Cryo-Blanching: Step-by-Step Processes

Blanching involves briefly boiling vegetables in hot water or steam to deactivate enzymes that cause spoilage and color loss, followed by rapid cooling in ice water. Cryo-blanching uses liquid nitrogen to freeze vegetables quickly, preserving color and nutrients more effectively by minimizing thermal degradation. Step-by-step, blanching requires heating, cooling, and drying, while cryo-blanching integrates rapid freezing and thawing processes to maintain vibrant color and texture.

Comparative Effects on Nutrient Retention

Blanching and cryo-blanching both aim to preserve the color and nutrients of vegetables, but cryo-blanching utilizes freezing temperatures that better maintain vitamin C and antioxidant levels. Compared to traditional blanching, cryo-blanching reduces nutrient loss by minimizing thermal degradation and enzymatic activity during processing.

- Vitamin C Retention - Cryo-blanching preserves up to 20% more vitamin C than conventional blanching methods.

- Antioxidant Levels - The freezing step in cryo-blanching significantly limits oxidation, enhancing antioxidant preservation.

- Thermal Damage Reduction - Cryo-blanching exposes vegetables to lower temperatures, preventing heat-induced nutrient breakdown.

These advantages make cryo-blanching a superior technique for maintaining nutritional quality during color preservation processing.

Visual Results: Side-by-Side Color Analysis

Blanching often results in a slight dulling of vegetable colors due to enzyme inactivation through heat exposure. Cryo-blanching, using liquid nitrogen or ultra-cold temperatures, preserves vibrant hues by immediately halting enzymatic activity without thermal degradation.

Side-by-side color analysis reveals cryo-blanched samples maintain higher color saturation and brightness compared to conventionally blanched counterparts. This visual advantage makes cryo-blanching preferable for products where visual appeal directly influences consumer preference.

Pros and Cons of Blanching for Color Preservation

Blanching is a common thermal process used to inactivate enzymes and preserve the color of vegetables, but it can cause some loss of vibrancy due to heat exposure. In contrast, cryo-blanching uses liquid nitrogen to rapidly cool products, better maintaining their natural colors and freshness.

- Effective enzyme inactivation - Blanching helps prevent enzymatic browning, preserving color during storage and processing.

- Color degradation risk - The heat in blanching can cause partial color loss and texture changes in sensitive vegetables.

- Energy intensive - Blanching requires high temperatures and longer processing times compared to cryo-blanching.

Advantages and Limitations of Cryo-Blanching

| Advantages of Cryo-Blanching | Cryo-blanching preserves vibrant food color by using liquid nitrogen or carbon dioxide, which rapidly cools and stabilizes pigments such as chlorophyll and carotenoids. This method reduces enzymatic browning more effectively than traditional hot water blanching, maintaining visual quality in vegetables and fruits. It also minimizes nutrient loss by avoiding exposure to high temperatures for extended periods. |

|---|---|

| Limitations of Cryo-Blanching | Cryo-blanching requires specialized equipment and cryogenic fluids, increasing operational costs and limiting accessibility for small-scale producers. The rapid cooling process can cause textural changes or surface damage if not carefully controlled. Additionally, safety concerns arise from handling extremely low-temperature gases, necessitating stringent protocols. |

Related Important Terms

Subzero Shock Blanching

Subzero Shock Blanching preserves color more effectively than traditional blanching by rapidly exposing vegetables to temperatures below zero, which inactivates enzymes without causing pigment degradation. This advanced cryo-blanching technique maintains vibrant hues and nutrient retention by minimizing thermal damage and cellular disruption.

Ultra-low Temperature Cryo-Blanching

Ultra-low Temperature Cryo-Blanching utilizes temperatures far below conventional blanching methods, effectively preserving the vibrant color and nutrient content of vegetables by minimizing enzymatic degradation and pigment loss. This advanced technique enhances visual appeal and shelf life, outperforming traditional blanching through superior retention of chlorophyll and carotenoids.

Liquid Nitrogen Flash Blanching

Liquid nitrogen flash blanching significantly enhances color preservation in vegetables by rapidly lowering the temperature, minimizing pigment degradation compared to traditional hot water blanching methods. This cryo-blanching technique retains chlorophyll and carotenoids more effectively, maintaining vibrant green and yellow hues during subsequent processing and storage.

Instantaneous Thermal Diffusion

Instantaneous thermal diffusion in cryo-blanching achieves superior color preservation by rapidly stabilizing pigments such as chlorophyll and anthocyanins, preventing enzymatic degradation more effectively than conventional blanching. This advanced heat transfer mechanism minimizes thermal exposure time, reducing pigment oxidation and maintaining vibrant color in processed fruits and vegetables.

Chlorophyll Retention Index

Cryo-blanching significantly enhances the Chlorophyll Retention Index compared to traditional blanching by reducing enzymatic degradation and preserving vibrant green pigments in vegetables. This method maintains higher chlorophyll content, resulting in superior color retention and improved visual quality in processed produce.

Pigment Stabilization Differential

Blanching stabilizes pigments like chlorophyll and carotenoids by inactivating enzymes, but conventional heat blanching often causes pigment degradation due to thermal stress. Cryo-blanching preserves color more effectively by using low temperatures that inhibit enzymatic activity while minimizing pigment breakdown, resulting in superior pigment stabilization and retention.

Texture Preservation Quotient

Cryo-blanching significantly improves the Texture Preservation Quotient by rapidly cooling vegetables, which minimizes cellular damage and maintains a firmer, crisper texture compared to conventional blanching. This advanced method reduces moisture loss and enzymatic degradation, resulting in enhanced color retention alongside superior structural integrity.

Phenolic Compound Shielding

Cryo-blanching significantly enhances the preservation of phenolic compounds compared to traditional blanching by minimizing enzymatic degradation and oxidative reactions during processing. This superior phenolic compound shielding helps maintain vibrant color and antioxidant properties in fruits and vegetables, optimizing nutritional quality and shelf-life.

Colorimetric Delta E Analysis

Colorimetric Delta E analysis reveals that cryo-blanching significantly reduces color degradation in vegetables compared to traditional blanching, preserving their vibrant hues more effectively by minimizing enzymatic browning and pigment loss. Studies indicate that the DE values for cryo-blanched samples remain consistently lower, demonstrating superior retention of natural color attributes critical for consumer acceptance and quality control in food processing.

Blanching vs Cryo-Blanching for color preservation. Infographic

cookingdiff.com

cookingdiff.com