Blanching involves briefly boiling food to inactivate enzymes and preserve quality before rapid chilling, while vacuum cooling rapidly reduces temperature by evaporative cooling under low pressure. Compared to blanching, vacuum cooling offers faster cooling rates and better moisture retention, making it ideal for leafy vegetables and delicate produce. However, blanching remains essential for enzyme control and microbial safety prior to subsequent cooling methods.

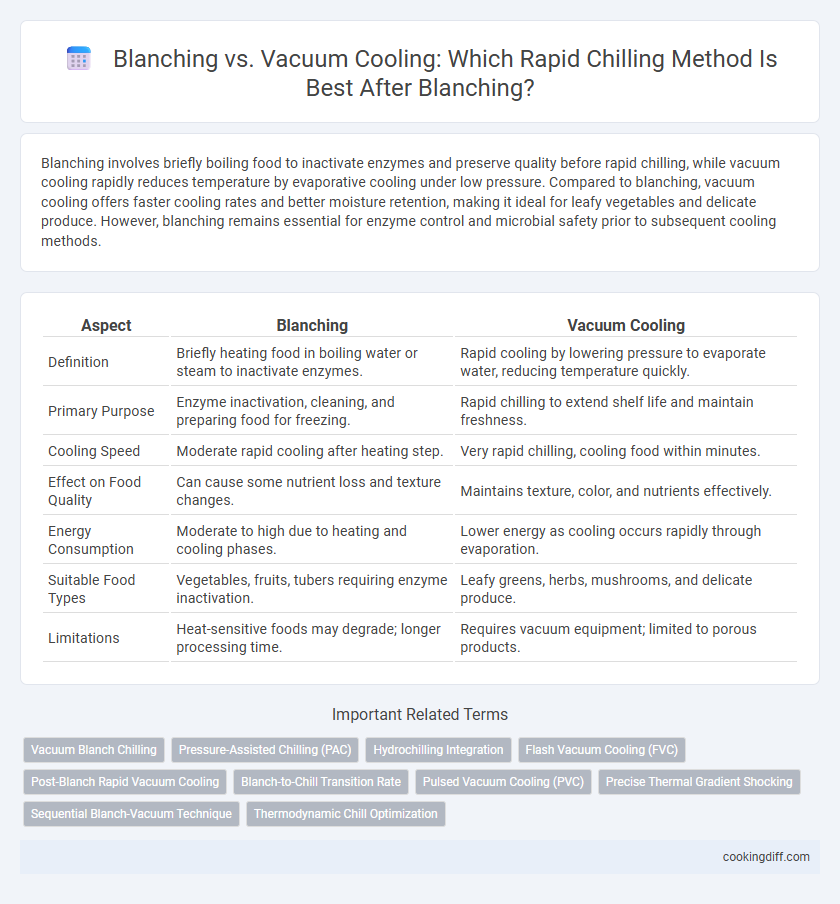

Table of Comparison

| Aspect | Blanching | Vacuum Cooling |

|---|---|---|

| Definition | Briefly heating food in boiling water or steam to inactivate enzymes. | Rapid cooling by lowering pressure to evaporate water, reducing temperature quickly. |

| Primary Purpose | Enzyme inactivation, cleaning, and preparing food for freezing. | Rapid chilling to extend shelf life and maintain freshness. |

| Cooling Speed | Moderate rapid cooling after heating step. | Very rapid chilling, cooling food within minutes. |

| Effect on Food Quality | Can cause some nutrient loss and texture changes. | Maintains texture, color, and nutrients effectively. |

| Energy Consumption | Moderate to high due to heating and cooling phases. | Lower energy as cooling occurs rapidly through evaporation. |

| Suitable Food Types | Vegetables, fruits, tubers requiring enzyme inactivation. | Leafy greens, herbs, mushrooms, and delicate produce. |

| Limitations | Heat-sensitive foods may degrade; longer processing time. | Requires vacuum equipment; limited to porous products. |

Introduction to Blanching and Rapid Chilling

Blanching is a heat treatment process used to inactivate enzymes in vegetables before freezing or further processing. Rapid chilling methods like vacuum cooling are employed to quickly reduce product temperature, preserving quality and extending shelf life.

- Blanching - involves brief exposure to hot water or steam to halt enzymatic activity and reduce microbial load.

- Vacuum Cooling - rapidly cools porous products by evaporative cooling under reduced pressure, minimizing texture damage.

- Comparison - blanching primarily prepares food for preservation, while vacuum cooling focuses on rapid temperature reduction post-blanching.

The Science Behind Blanching

How does blanching scientifically differ from vacuum cooling in rapid chilling processes? Blanching involves briefly exposing food to boiling water or steam to inactivate enzymes and reduce microbial load, which slows down degradation and enhances shelf life. Vacuum cooling rapidly lowers the temperature by evaporative cooling under reduced pressure, focusing on moisture removal rather than enzyme inactivation.

Understanding Vacuum Cooling Technology

Vacuum cooling technology rapidly chills products by reducing atmospheric pressure, causing water to evaporate and remove heat efficiently. This method preserves freshness and extends shelf life by cooling produce more uniformly than traditional blanching.

Unlike blanching, which uses hot water or steam and can degrade texture and nutrients, vacuum cooling minimizes thermal damage. The process is energy-efficient and ideal for leafy greens, herbs, and delicate produce requiring fast, gentle cooling.

Blanching vs Vacuum Cooling: Key Differences

| Aspect | Blanching | Vacuum Cooling |

|---|---|---|

| Process | Brief exposure of food to boiling water or steam to inactivate enzymes. | Rapid cooling by lowering pressure, causing water to evaporate and absorb heat. |

| Purpose | Preserves color, texture, and nutritional value before freezing or drying. | Quickly reduces temperature to inhibit microbial growth post-harvest. |

| Cooling Speed | Slower cooling rate due to heat absorption during blanching. | Extremely fast cooling, reducing product temperature in minutes. |

| Impact on Food Quality | May cause slight nutrient loss and textural changes from heat exposure. | Maintains freshness and moisture with minimal nutrient degradation. |

Efficiency in Rapid Chilling: Which Method Prevails?

Blanching uses high-temperature steam or hot water to rapidly elevate surface temperatures, which is less efficient for cooling compared to vacuum cooling that removes heat through rapid pressure reduction. Vacuum cooling achieves faster temperature drops by evaporating moisture under reduced pressure, resulting in a more energy-efficient chilling process.

- Blanching Efficiency - Blanching requires thermal energy and time to cool, leading to slower overall chilling speed compared to vacuum cooling.

- Vacuum Cooling Speed - Vacuum cooling reduces product temperature within minutes by exploiting rapid vaporization under low pressure environments.

- Energy Consumption - Vacuum cooling generally consumes less energy due to direct evaporation cooling, enhancing rapid chilling efficiency over blanching.

Impact on Nutrient and Color Retention

Blanching involves briefly scalding vegetables in hot water or steam, which can cause some loss of water-soluble vitamins like vitamin C but helps preserve color by inactivating enzymes that cause browning. This process stabilizes chlorophyll in green vegetables, resulting in a brighter appearance after cooling.

Vacuum cooling rapidly reduces temperature by evaporative cooling under low pressure, minimizing nutrient degradation and better preserving natural color compared to blanching. The gentle cooling method maintains the integrity of heat-sensitive nutrients and vibrant pigments such as carotenoids and anthocyanins.

Energy Consumption and Cost Considerations

Blanching consumes less energy than vacuum cooling due to shorter processing times and lower equipment requirements, resulting in reduced operational costs. Vacuum cooling, while effective for rapid chilling, involves higher initial investment and energy usage linked to maintaining low-pressure environments.

- Energy Efficiency - Blanching requires less electricity per kilogram of product compared to vacuum cooling.

- Capital Costs - Vacuum cooling systems demand higher upfront expenditure on specialized vacuum pumps and chambers.

- Operational Costs - Blanching maintains lower ongoing utility costs due to simpler equipment and shorter cycle times.

Considering both energy consumption and cost, blanching is often the more economical choice for rapid chilling in many food processing applications.

Applications in Food Processing Industries

Blanching is widely used in food processing industries to inactivate enzymes and prepare vegetables for freezing, while vacuum cooling rapidly reduces the temperature of cooked foods like leafy greens and pasta by evaporative cooling under reduced pressure. Vacuum cooling offers efficient chilling that preserves texture and extends shelf life, making it ideal for delicate products where moisture retention is crucial. Both methods enhance food safety and quality, but vacuum cooling provides faster cooling rates and energy efficiency in high-throughput operations.

Safety and Food Quality Outcomes

Blanching uses steam or hot water to quickly inactivate enzymes and reduce microbial load, enhancing food safety and preserving color and texture. This method is widely applied in vegetables to maintain quality before freezing or further processing.

Vacuum cooling rapidly lowers food temperature by evaporating surface moisture under reduced pressure, minimizing microbial growth while preserving freshness. It is particularly effective for leafy greens and prepared meals where moisture retention is crucial for texture. Both techniques improve food quality and safety, but blanching offers better enzymatic inactivation, whereas vacuum cooling excels in rapid chilling without cooking effects.

Related Important Terms

Vacuum Blanch Chilling

Vacuum blanch chilling combines the rapid cooling benefits of vacuum cooling with blanching's enzyme inactivation, enhancing shelf life and preserving texture and color in vegetables. This method reduces cooling time by up to 70% compared to traditional blanching, minimizing nutrient loss and microbial growth effectively.

Pressure-Assisted Chilling (PAC)

Pressure-Assisted Chilling (PAC) enhances rapid chilling by utilizing controlled pressure reduction to accelerate heat transfer, offering superior speed and quality preservation compared to traditional blanching and vacuum cooling methods. PAC minimizes moisture loss and maintains food texture by combining pressure modulation with chilling, making it an efficient alternative for high-value perishables.

Hydrochilling Integration

Blanching rapidly heats vegetables to inactivate enzymes, while vacuum cooling quickly reduces temperature by evaporative cooling, offering complementary benefits for preserving quality; integrating hydrochilling before vacuum cooling enhances heat removal efficiency and reduces surface temperature, optimizing the rapid chilling process. The combination of blanching, hydrochilling, and vacuum cooling improves microbial safety, retains texture, and extends shelf life more effectively than either method alone.

Flash Vacuum Cooling (FVC)

Flash Vacuum Cooling (FVC) rapidly chills food products by reducing pressure to vaporize water, enabling faster heat removal compared to conventional blanching. FVC preserves texture, color, and nutrient content better than blanching, making it ideal for maintaining fresh quality in leafy greens and baked goods.

Post-Blanch Rapid Vacuum Cooling

Post-blanch rapid vacuum cooling significantly reduces the temperature of vegetables within minutes, preserving texture, color, and nutritional quality better than traditional methods. This technique minimizes microbial growth and enzymatic activity by combining the heat inactivation of blanching with the accelerated cooling effect of vacuum technology.

Blanch-to-Chill Transition Rate

Blanching rapidly denatures enzymes and initiates cellular structure modification, accelerating the blanch-to-chill transition rate compared to vacuum cooling, which primarily removes heat via pressure reduction but lacks enzymatic effect. This faster transition in blanching improves microbial safety and preserves texture by reducing the time produce remains in the temperature danger zone.

Pulsed Vacuum Cooling (PVC)

Pulsed Vacuum Cooling (PVC) offers a faster chilling process compared to traditional blanching by rapidly reducing the temperature through intermittent vacuum pulses, enhancing the cooling rate without compromising product quality. PVC's controlled pressure cycles improve moisture retention and minimize thermal damage, making it a superior method for preserving texture and nutrient content during rapid chilling.

Precise Thermal Gradient Shocking

Blanching achieves rapid chilling by exposing produce to precise thermal gradient shocking, using hot water or steam to rapidly raise internal temperatures before cooling, which effectively inactivates enzymes and preserves texture. Vacuum cooling, in contrast, relies on pressure reduction to evaporate moisture and cool produce rapidly, but lacks the controlled thermal gradient essential for enzyme inactivation found in blanching.

Sequential Blanch-Vacuum Technique

The Sequential Blanch-Vacuum Technique combines the thermal inactivation benefits of blanching with the rapid moisture evaporation in vacuum cooling, resulting in faster chilling rates and improved microbial safety. This method enhances shelf life and preserves texture by minimizing enzymatic activity and optimizing heat removal under reduced pressure conditions.

Blanching vs Vacuum Cooling for rapid chilling. Infographic

cookingdiff.com

cookingdiff.com