Using an ice bath after blanching rapidly cools vegetables to stop the cooking process and preserve texture and color, but it can be time-consuming and less energy-efficient. A blast chiller offers a faster and more consistent cooling method, reducing the risk of bacterial growth while maintaining the quality of blanched produce. Choosing between an ice bath and a blast chiller depends on batch size, cooling speed requirements, and available resources.

Table of Comparison

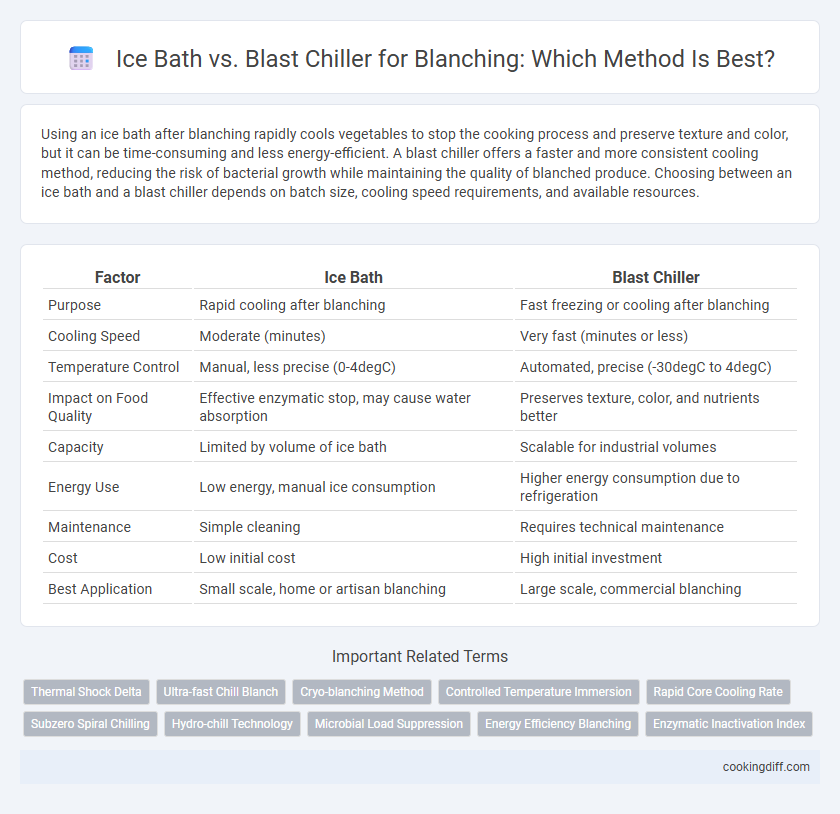

| Factor | Ice Bath | Blast Chiller |

|---|---|---|

| Purpose | Rapid cooling after blanching | Fast freezing or cooling after blanching |

| Cooling Speed | Moderate (minutes) | Very fast (minutes or less) |

| Temperature Control | Manual, less precise (0-4degC) | Automated, precise (-30degC to 4degC) |

| Impact on Food Quality | Effective enzymatic stop, may cause water absorption | Preserves texture, color, and nutrients better |

| Capacity | Limited by volume of ice bath | Scalable for industrial volumes |

| Energy Use | Low energy, manual ice consumption | Higher energy consumption due to refrigeration |

| Maintenance | Simple cleaning | Requires technical maintenance |

| Cost | Low initial cost | High initial investment |

| Best Application | Small scale, home or artisan blanching | Large scale, commercial blanching |

Introduction to Blanching: Why Cooling Matters

Blanching is a crucial food processing step that involves briefly boiling vegetables to halt enzyme activity and preserve color, texture, and nutritional value. Rapid cooling after blanching prevents overcooking and microbial growth, ensuring product quality and safety.

Ice baths and blast chillers are two common cooling methods used post-blanching; ice baths cool vegetables quickly through direct contact with chilled water, while blast chillers use cold air circulation to reduce temperature rapidly. Choosing the appropriate cooling technique impacts the efficiency of heat removal and the final texture of the blanched produce.

What is an Ice Bath? Process and Benefits

An ice bath rapidly cools blanched vegetables by submerging them in ice water to halt the cooking process and preserve texture and color. This method is simple and effective for small batches but can be less efficient for large-scale operations.

- Rapid cooling - Ice baths quickly stop the cooking process to prevent overcooking and nutrient loss.

- Texture preservation - Immersing foods in ice water maintains crispness and vibrant color.

- Cost-effective - Requires minimal equipment, making it affordable for small kitchens.

Understanding Blast Chillers in the Kitchen

| Ice Bath | Rapidly cools blanched foods by immersing them in cold water, effectively halting the cooking process and preserving color and texture. Ideal for small batches but can be labor-intensive and less consistent in temperature control. |

| Blast Chiller | Utilizes powerful refrigeration to quickly reduce the temperature of food, ensuring uniform cooling and reducing bacterial growth. Suitable for large-scale kitchens where consistent and hygienic cooling is critical for food safety and quality. |

| Understanding Blast Chillers | Blast chillers rapidly lower the internal temperature of blanched foods, optimizing preservation of nutrients and texture while minimizing thermal shock. They provide precise temperature control and energy efficiency, making them essential in professional culinary environments. |

How Ice Baths Work for Blanching

Ice baths rapidly cool blanched vegetables by immersing them in chilled water, effectively halting the cooking process and preserving texture, color, and nutrients. The cold temperature, typically between 0degC to 4degC, inhibits enzyme activity that can cause deterioration. This method is simple, cost-effective, and widely used in both home kitchens and commercial food preparation to ensure optimal quality after blanching.

Blast Chiller Mechanics in Blanching

Blast chillers rapidly reduce the temperature of blanched vegetables by circulating cold air at high velocity, preserving texture and nutrients better than traditional ice baths. This method minimizes microbial growth by swiftly passing through the temperature danger zone after blanching.

Blast chiller mechanics rely on powerful refrigeration systems and optimized airflow to uniformly cool produce within minutes. Unlike an ice bath, which can waterlog vegetables and dilute flavor, blast chillers maintain product integrity and firmness. Energy efficiency and reduced water usage make blast chillers an eco-friendly choice in commercial blanching processes.

Speed of Cooling: Ice Bath vs Blast Chiller

Ice baths cool blanched vegetables by rapidly reducing their temperature through direct contact with cold water, typically achieving cooling within 2 to 5 minutes. This method helps preserve texture and color but may introduce excess moisture, affecting product quality.

Blast chillers use powerful refrigeration fans to remove heat quickly, cooling produce evenly in 20 to 40 minutes without added water, minimizing moisture uptake. This technology ensures consistent temperature control and extends shelf life by reducing microbial growth after blanching.

Food Quality and Texture After Cooling

Ice baths rapidly stop the cooking process after blanching, preserving vibrant color and crisp texture by preventing overcooking and enzymatic browning. Blast chillers cool vegetables more evenly and quickly, reducing microbial growth while maintaining firmness and nutrient retention. Both methods enhance food quality, but blast chillers offer superior control over texture and safety in large-scale operations.

Safety and Foodborne Pathogen Control

Ice baths are commonly used to halt cooking after blanching but present risks of cross-contamination if not properly managed. Blast chillers rapidly reduce food temperature, significantly minimizing the growth of foodborne pathogens during cooling.

- Ice Bath Contamination Risk - Ice baths can harbor bacteria if the water is not regularly changed and sanitized.

- Blast Chiller Efficiency - Blast chillers cool food quickly, reducing the time food spends in the temperature danger zone (40degF-140degF).

- Pathogen Control - Rapid cooling with blast chillers limits pathogen proliferation better than ice baths.

Using blast chillers after blanching offers a safer method for controlling foodborne pathogens compared to traditional ice baths.

Cost and Accessibility: Which Method Wins?

Which method is more cost-effective and accessible for blanching, ice bath or blast chiller? Ice baths require minimal investment and use common household items, making them highly accessible for small-scale or home cooks. Blast chillers involve higher initial costs and complex maintenance, but they provide consistent temperature control and faster cooling times for commercial kitchens.

Related Important Terms

Thermal Shock Delta

Ice baths create a rapid thermal shock delta by quickly lowering the temperature of blanched vegetables, preserving texture and color through immediate cooling. Blast chillers offer a controlled, uniform temperature drop with a smaller thermal shock delta, optimizing food safety while reducing moisture loss and preventing quality degradation.

Ultra-fast Chill Blanch

Ultra-fast Chill Blanch using a blast chiller rapidly cools vegetables after blanching by reducing their temperature within minutes, preserving texture, color, and nutritional quality more effectively than traditional ice baths. While ice baths slow cooling and risk water absorption, blast chillers ensure hygienic, consistent, and energy-efficient chilling, ideal for high-volume commercial blanching processes.

Cryo-blanching Method

Cryo-blanching uses rapid cooling with a blast chiller to preserve color, texture, and nutrients, outperforming traditional ice bath methods that often leave vegetables waterlogged and less crisp. The blast chiller's precise temperature control minimizes enzymatic activity and microbial growth, ensuring superior quality and extended shelf life in processed vegetables.

Controlled Temperature Immersion

Controlled temperature immersion during blanching is most effectively achieved with an ice bath, which rapidly reduces the temperature of vegetables to preserve texture and nutrients by halting the cooking process. Blast chillers, while efficient at cooling larger volumes quickly, typically do not provide the precise temperature control necessary for optimal blanching and may result in uneven cooling or compromised product quality.

Rapid Core Cooling Rate

Ice baths provide rapid core cooling by immediate immersion in chilled water, effectively halting enzymatic activity after blanching with high thermal conductivity. Blast chillers achieve accelerated core temperature reduction through forced cold air circulation, offering consistent cooling rates ideal for large batches but with slightly slower core cooling compared to ice baths.

Subzero Spiral Chilling

Subzero Spiral Chilling offers precise temperature control and rapid cooling rates compared to traditional ice baths, significantly preserving texture and nutrient retention in blanched vegetables. Unlike blast chillers, the spiral design maximizes airflow and minimizes chilling time, enhancing overall product quality and food safety efficiency during the blanching process.

Hydro-chill Technology

Hydro-chill technology uses rapid cooling with ice water immersion, effectively preserving color, texture, and nutrient content after blanching by quickly halting enzymatic activity. Compared to blast chillers that cool through cold air, hydro-chilling provides uniform temperature reduction, reducing physiological damage and extending the shelf life of blanched vegetables.

Microbial Load Suppression

Ice baths rapidly cool blanched vegetables to suppress microbial growth by quickly reducing surface temperature, while blast chillers provide uniform cooling at controlled low temperatures, effectively minimizing microbial load through consistent thermal shock. Studies indicate blast chillers enhance food safety by lowering bacterial counts more efficiently than traditional ice baths in post-blanching processes.

Energy Efficiency Blanching

Ice baths consume significantly more water and energy due to continuous ice replenishment, whereas blast chillers optimize energy use by rapidly cooling blanched vegetables with controlled airflow and temperature settings. Blast chillers minimize thermal shock and microbial growth while reducing overall energy consumption, making them a more sustainable choice for energy-efficient blanching processes.

Ice bath vs Blast chiller for blanching. Infographic

cookingdiff.com

cookingdiff.com